With Tekla's rebar detailing, you can:

Recommended products and services for you

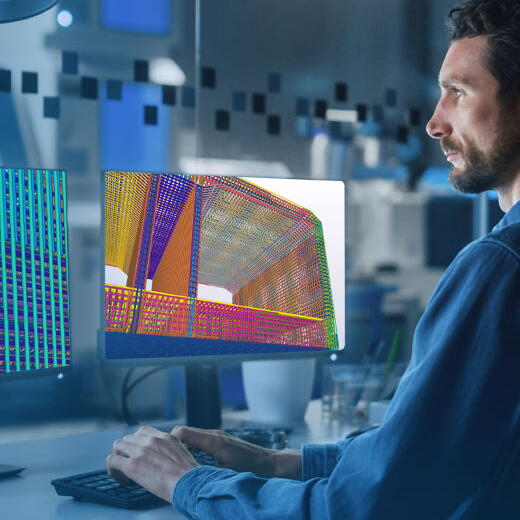

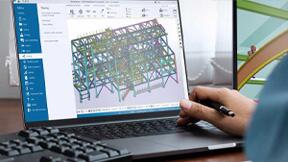

Tekla Structures

Structural design engineers, detailers, fabricators, contractors, and project managers can create, combine, manage and share accurate models for every project.

Learn more & try for free

Tekla Model Sharing for Tekla Structures

Tekla Structures users can work with a truly innovative BIM collaboration platform on local copies of a model.

Learn more

Trimble Connect

Everyone involved in your project can handle truly constructible data with the Trimble Connect collaboration platform.

Learn more

Tekla Warehouse

This is a free, global BIM storage of Tekla Structures add-ons, libraries, and templates. Have an easy, convenient way to produce your high-quality models efficiently.

Visit Tekla WarehouseLearn more about rebar detailing

We are here to help you

Find your local Tekla contact or send a request for us to contact you.