Project description

In the city center of Leiden, the current, temporary bridge called the ‘Valkbrug’ is being replaced by a new permanent bridge. The project is part of the renovation of the adjacent square called the ‘Lammermarkt’.

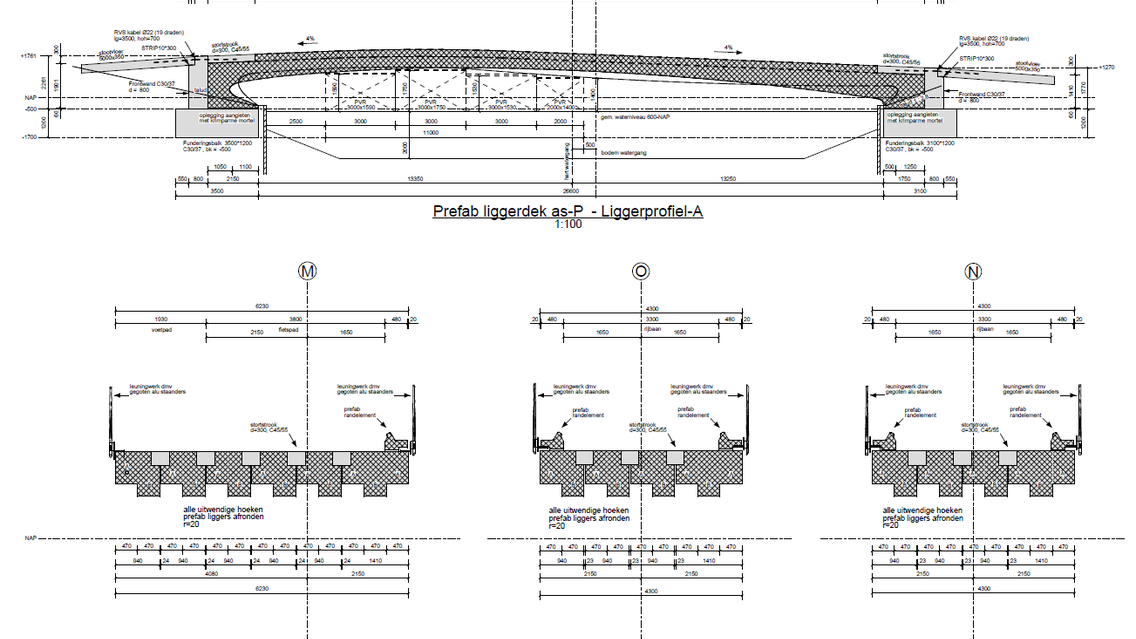

The bridge has been designed by NEY & Partners and consists of four bridges with a span of over 30 meters. The four bridges merge together on the south side. The bottom of the bridge has been designed to be a variation of two different concrete beams that vary in profile. This accentuates the space underneath the bridge and gives it a very special feeling. In this way, the architect emphasizes the importance of water for the city of Leiden. To keep the bridge as slender as possible, it is constructed as an integral bridge and will be integrally linked with its abutments and piles. In addition to that, there will be no visible seams and the bridge will blend into the surrounding terrain. The railing is constructed from cast aluminum and will be connected to the bridge with steel plates. Because the railing is slightly bent and the uprights can be placed in eight different orientations, the bridge will look like it is surrounded by a curtain of reeds.

Special challenges

The big challenge within this project was the urban environment combined with the shape of the bridge. Between the two banks of the canal there was a relatively large difference in height. The difference had to be bridged and within the stated requirements (maximum slope and clearance gauge underneath the bridge) combined with the high design requirements in accordance with the aesthetic quality plan. To realize this, we looked at three different variants to minimize the necessary embankment on the south side. Eventually, in consultation with the client, the bridge moved a few meters to the south to blend the bridge in its environment to the best extent possible.

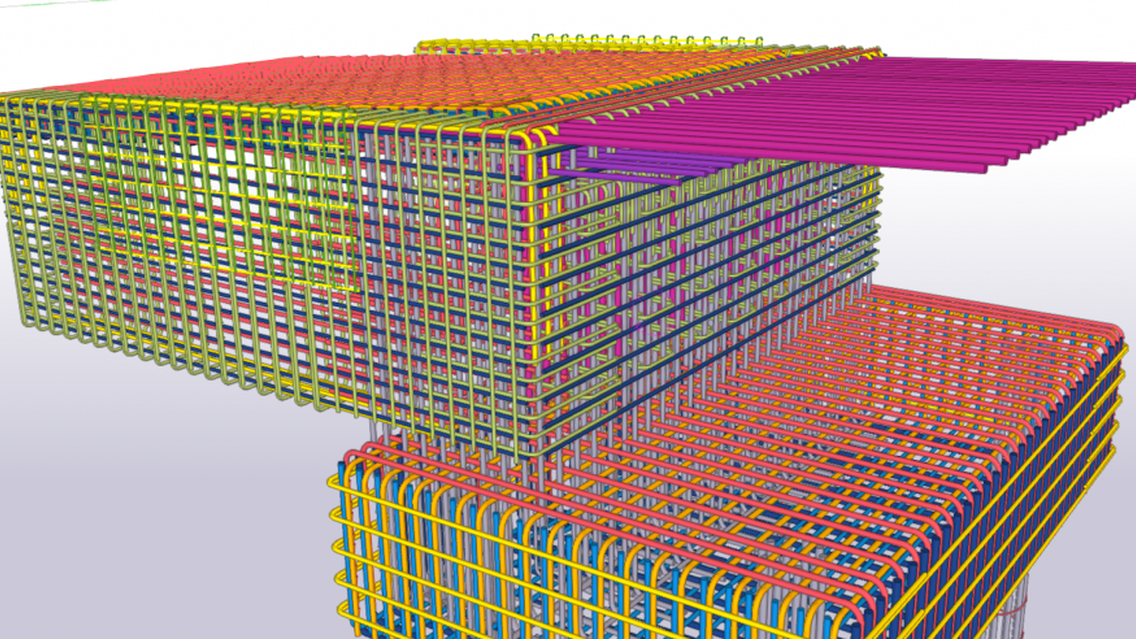

Taking into account the complex shape of the beams and the required aesthetics, the decision was made to prefabricate them. The biggest beams each have a weight of over 90 metric tons and are produced in a formwork made especially for this project.

What made the project successful

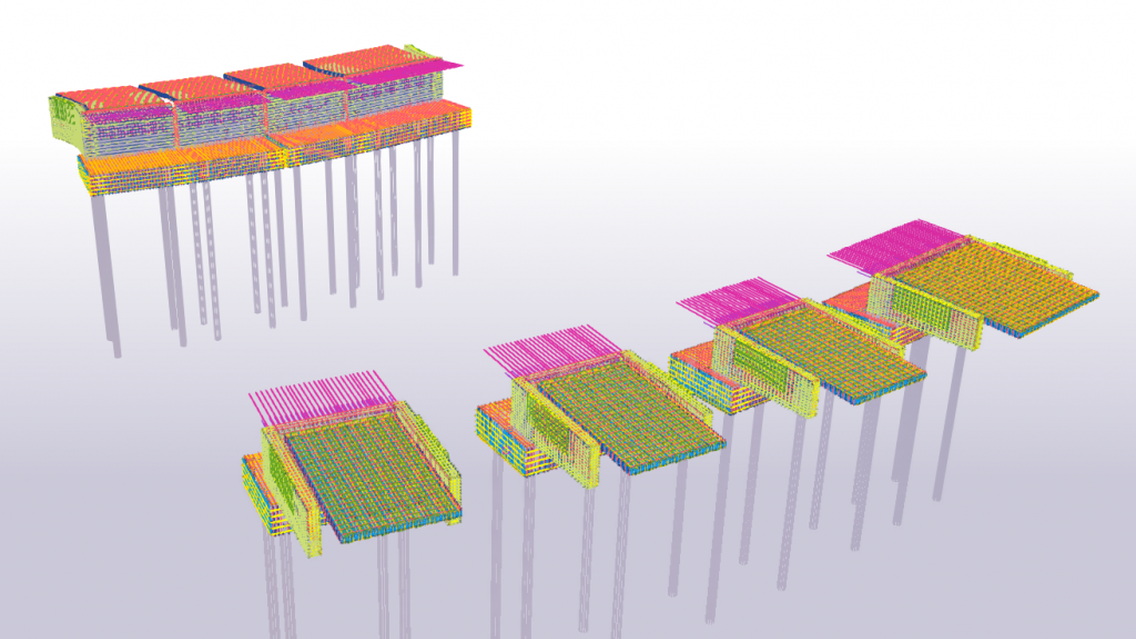

The construction of the bridge has been completely elaborated in a 3D BIM model. Within this model, the overlapping fields of engineering are optimally managed and also the aesthetics are guaranteed. In a later stage of the project, the rebar was also incorporated into the model. Therefore, all the cast-in-place concrete parts were completely modeled in 3D in Tekla, including the rebar. With the model as a base, the production drawings of the beams, the railing and the bump protections were created. By incorporating the rebar in the model, we have solved some complex intersections in advance, thereby avoiding issues in the execution phase.