Detailing 3 moving structures for the coke production plant

Cube has been appointed by Paul Wurth Spa as the company responsible for calculation, detailing of 3 moving structures for the coke production plant in Cherepovets, Russia.

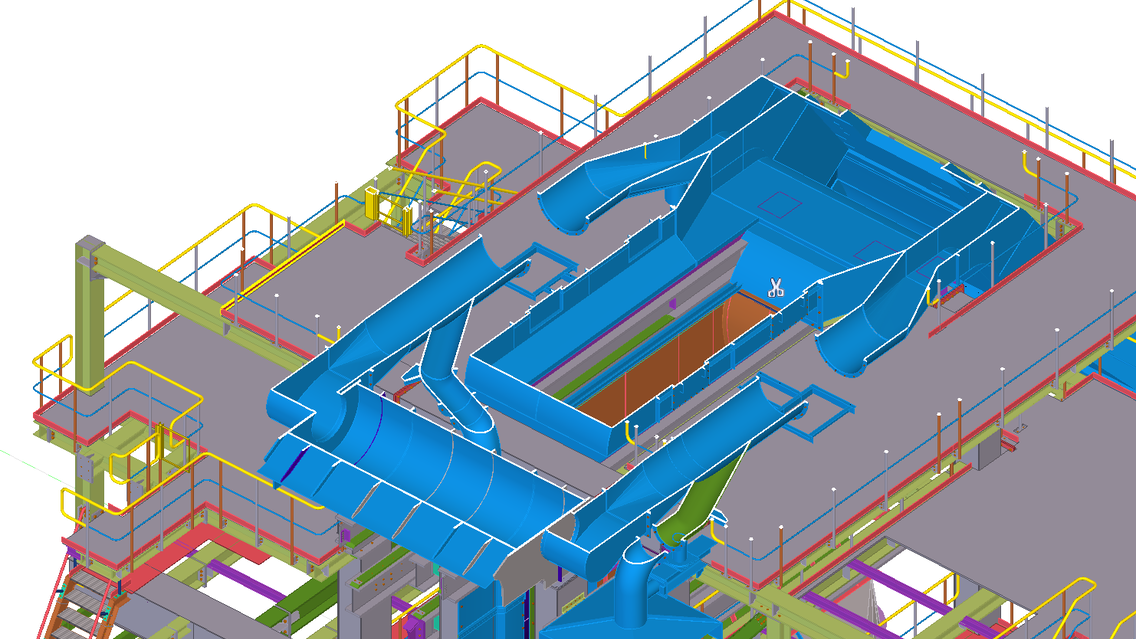

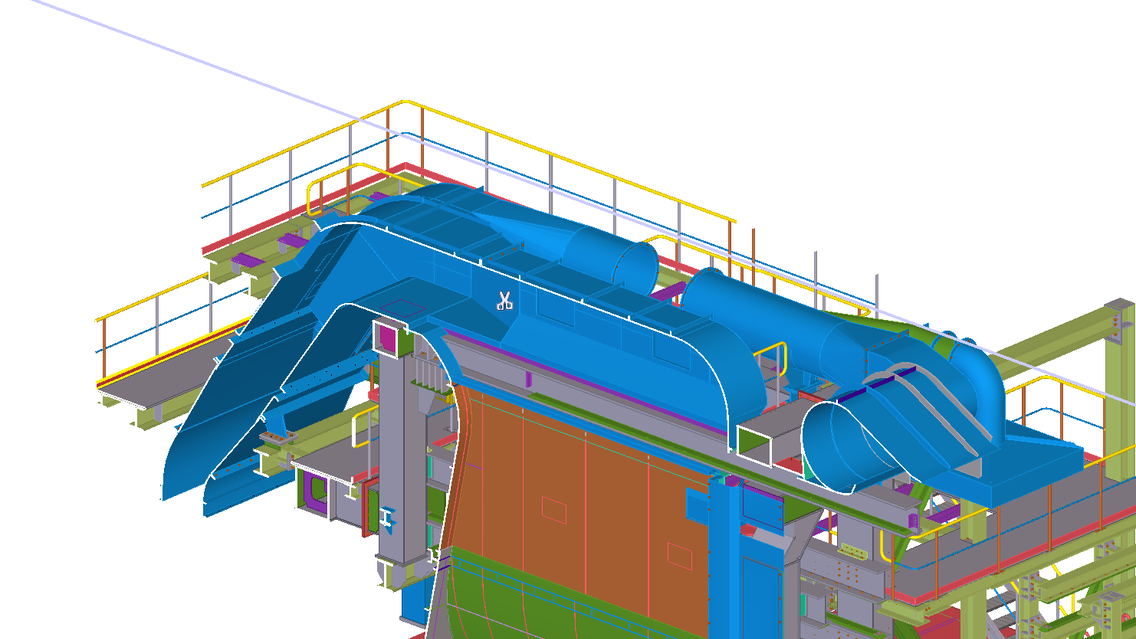

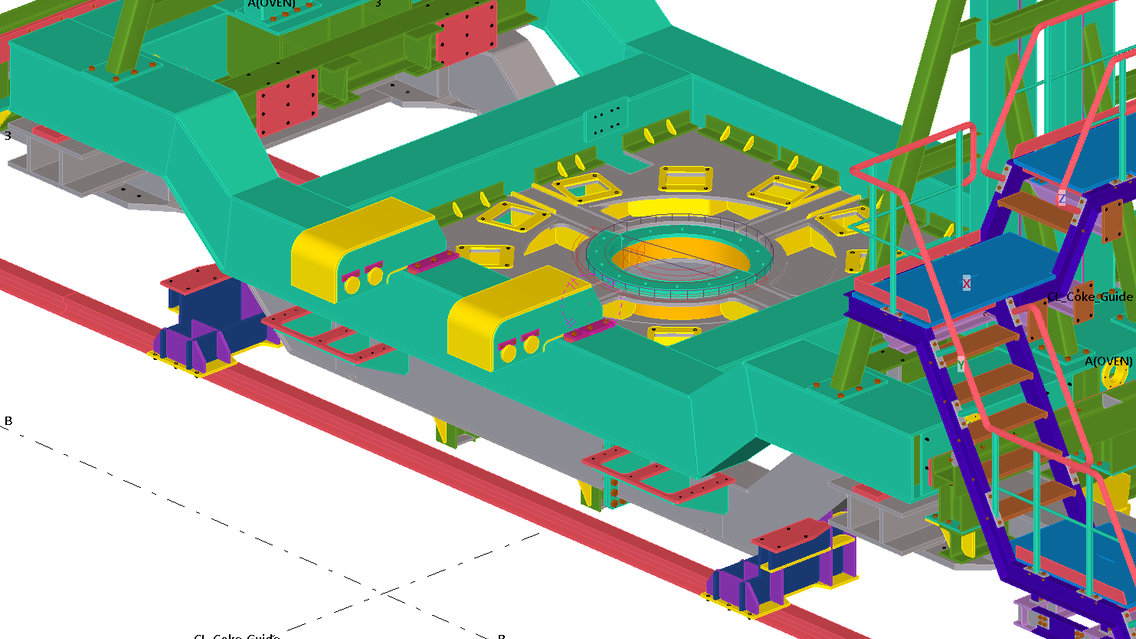

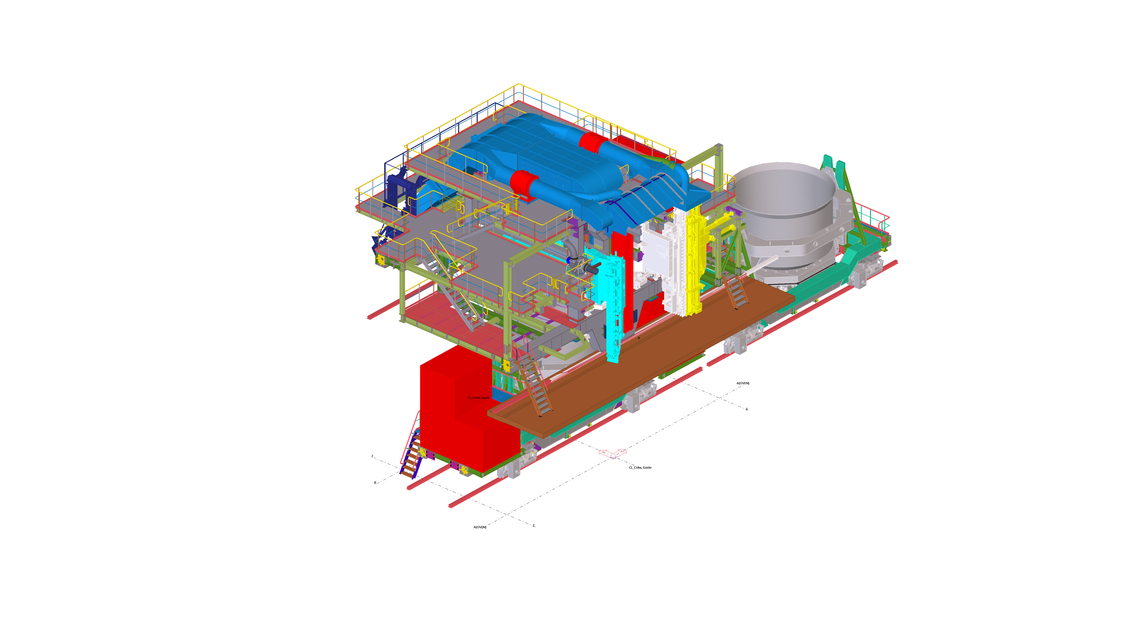

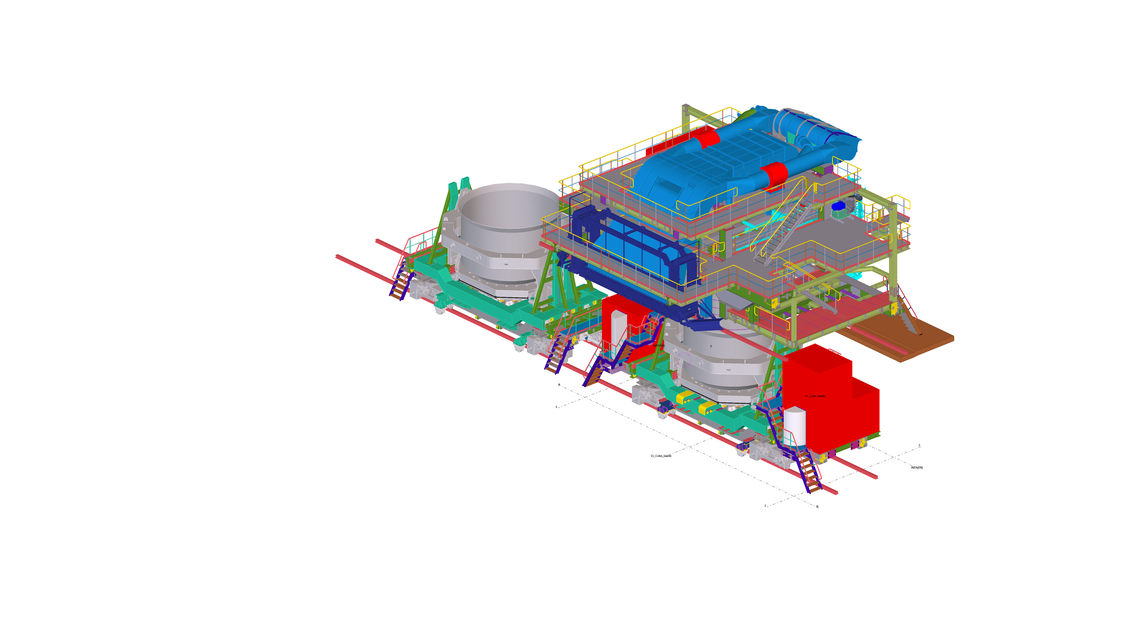

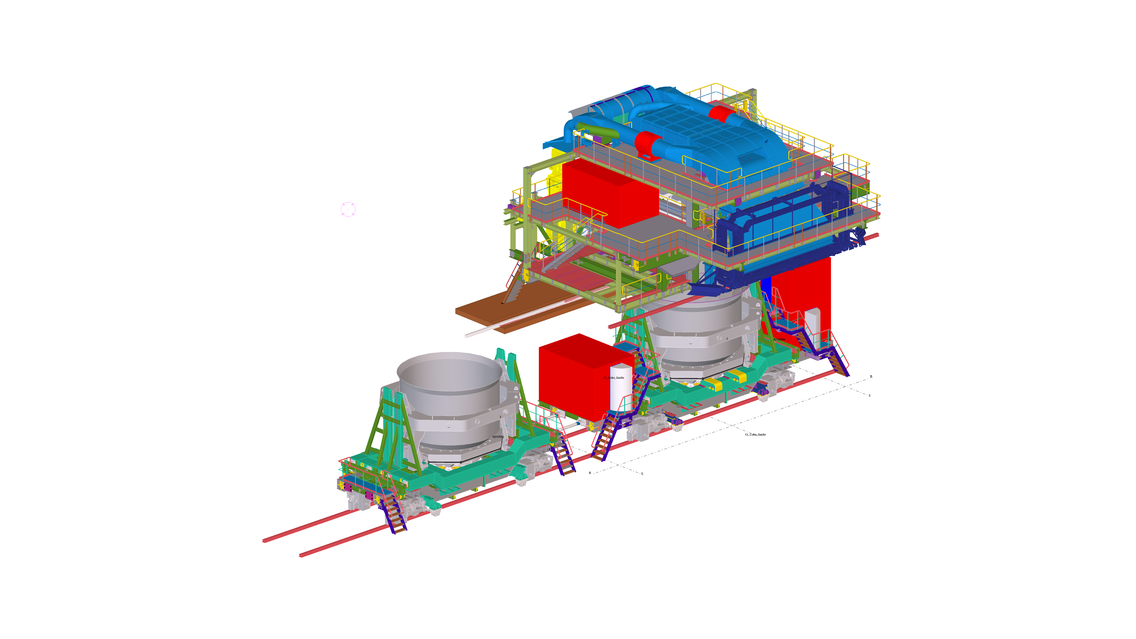

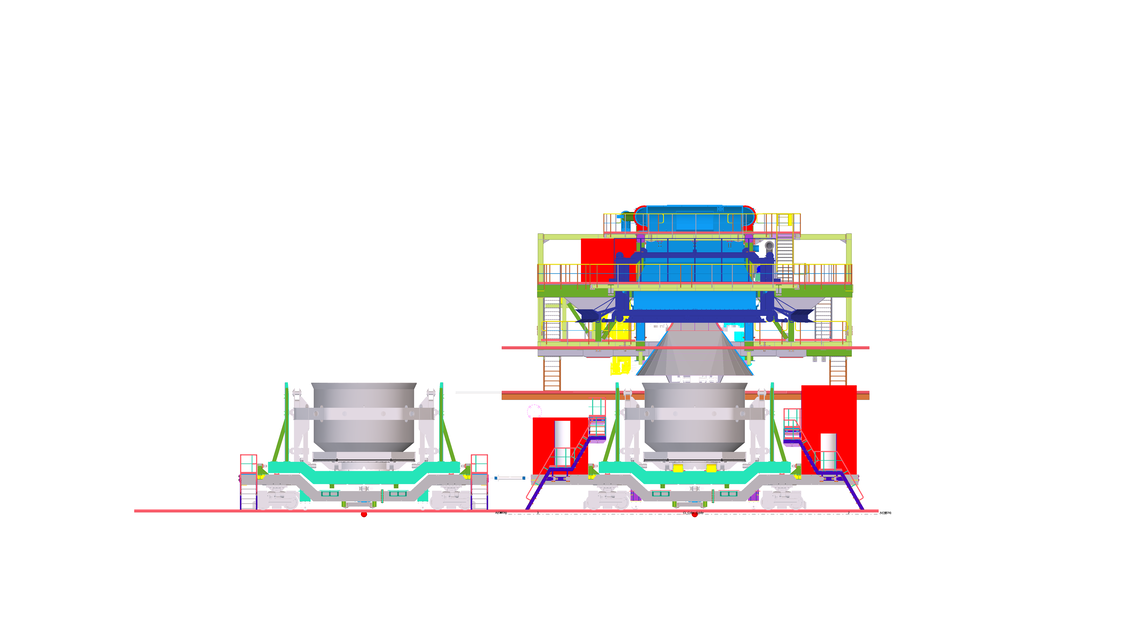

The 3 structures (respectively idle and driven bucket cars and coke transfer car) are similar to machines due to complexity and numbers of mechanical interfaces and devices, and are moving along rail-like boogies.

The coke transfer car extracts coke directly from the coke oven and transfers it on bucket cars running below with a capacity of 60 tons.

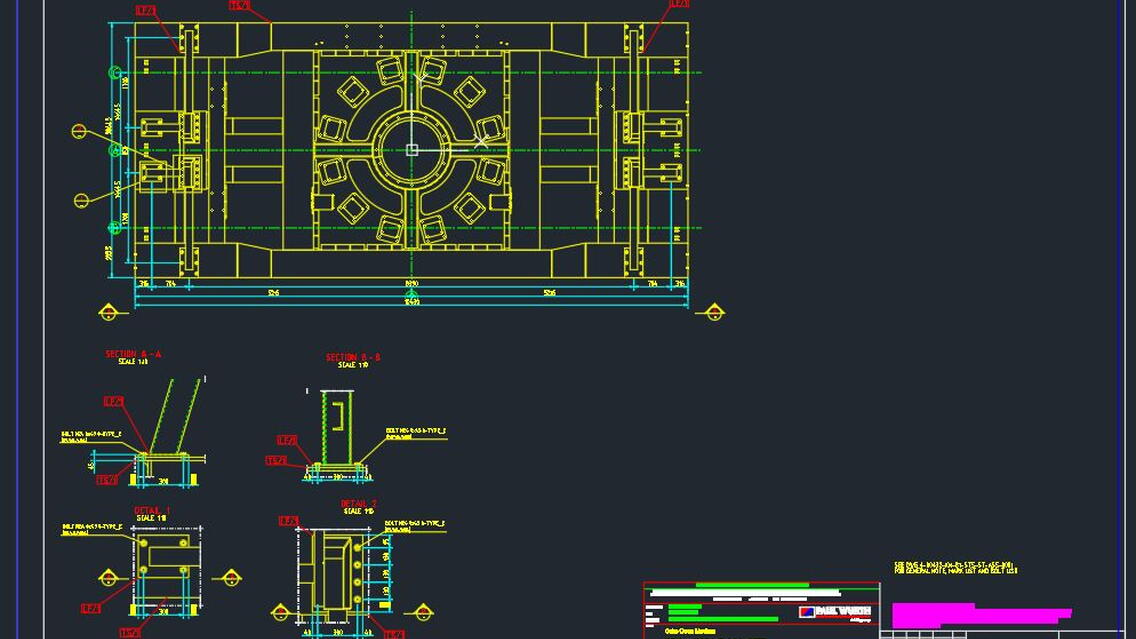

The overall weight of the machines is over 600 tons. They have been developed via over 250 drawings other than model sharing for take-off quantity.

Challenges and success

Key points of the project can be summed up in the following:

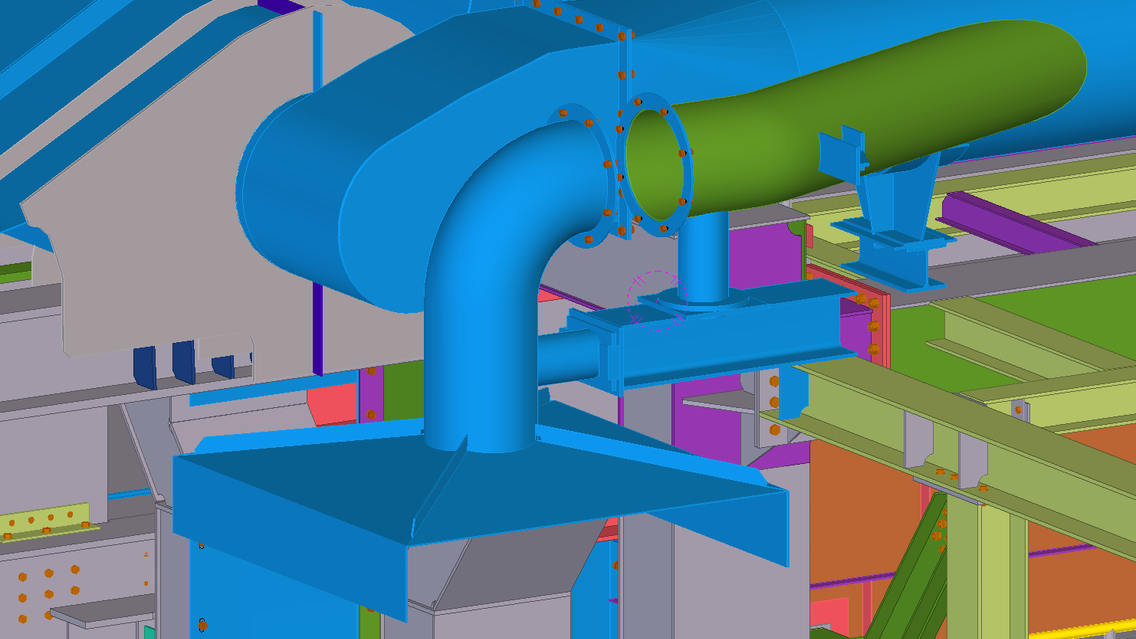

- Multi-disciplinary project with continuous monitoring and checking of interfaces, movable parts and piping items.

- Continuous design variables in terms of mechanical input that, while being a leader for milestones and structural deliverables, was constantly late. Consequently the structural engineering had to be readily adaptable to changing in terms of modeling and drafting retrofit.

- The cars have been built in different production sites with consequent requests for personalization in terms of output, shipping dimensions and transportation means.

- Strict time line due to inaccessibility of the site plant during the winter period.

This has been a non-typical project where integration of Tekla parametric modeling has been used in interface with calculation model (SAP2000) and as a shared data model for mechanical sides, together with instruments for time valuation and scheduling.

A whole 3D model has been managed and consequently transformed in a wide data-base (federate model)