New production building for the paper factory

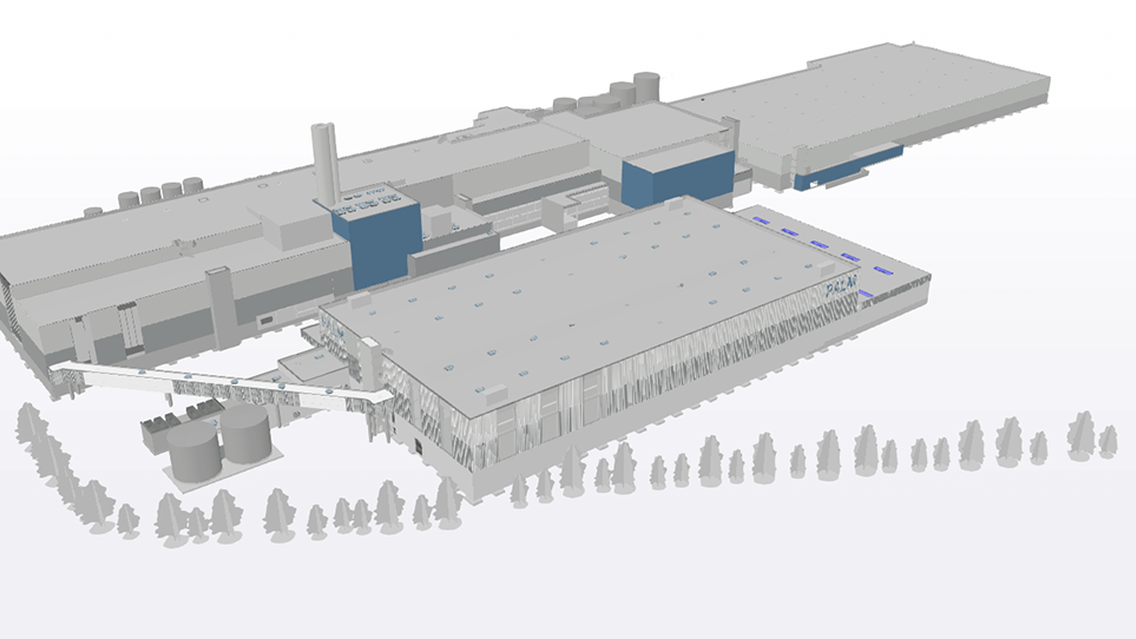

The project is a new production building for the paper factory Papierfabrik Palm GmbH & Co. KG at the headquarters of the company in Aalen-Neukochen.

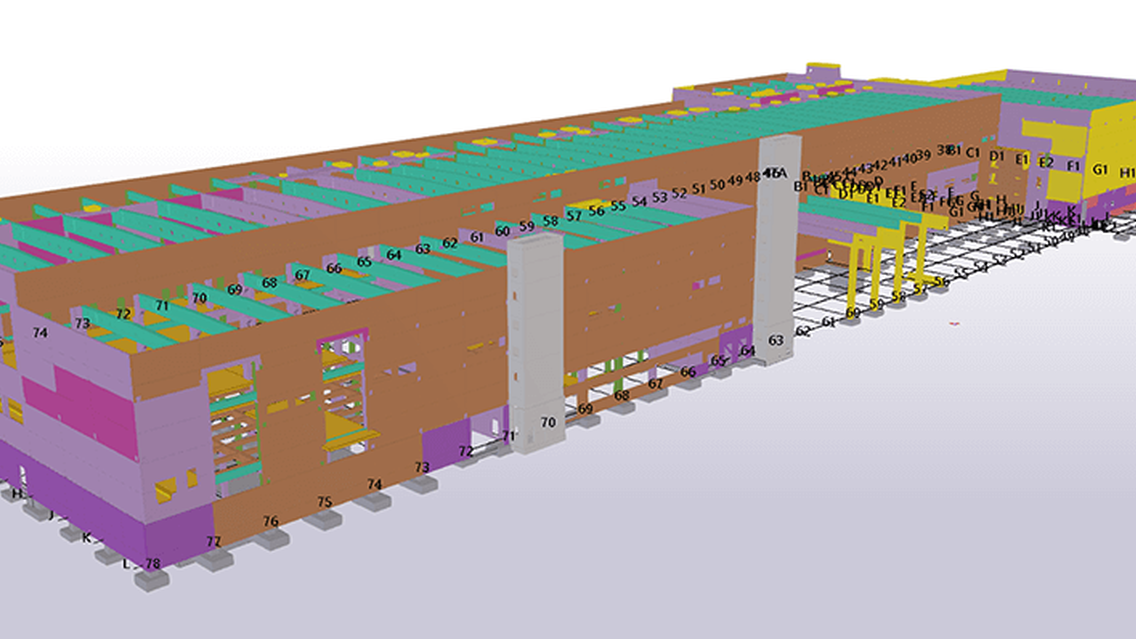

In total, Bau-Consult Hermsdorf is responsible for the construction of five individual buildings. These accommodate the entire production chain for corrugated base paper – from raw material preparation to production and delivery. The BIM awards entry focuses on paper factory 5 (PM 5).

The new building will replace three operating paper machines on the company premises. In order to minimize downtimes in ongoing production, the plant was planned on the basis of sub-projects. The projects for ’material preparation’ and ’paper machine’ are currently in the shell construction phase. The overall project is scheduled to be completed in 2022. Bau-Consult Hermsdorf (BCH) is responsible for the precast design and detailing as well as parts of the structural design, formwork and reinforcement planning for the entire project.

Success factors & challenges

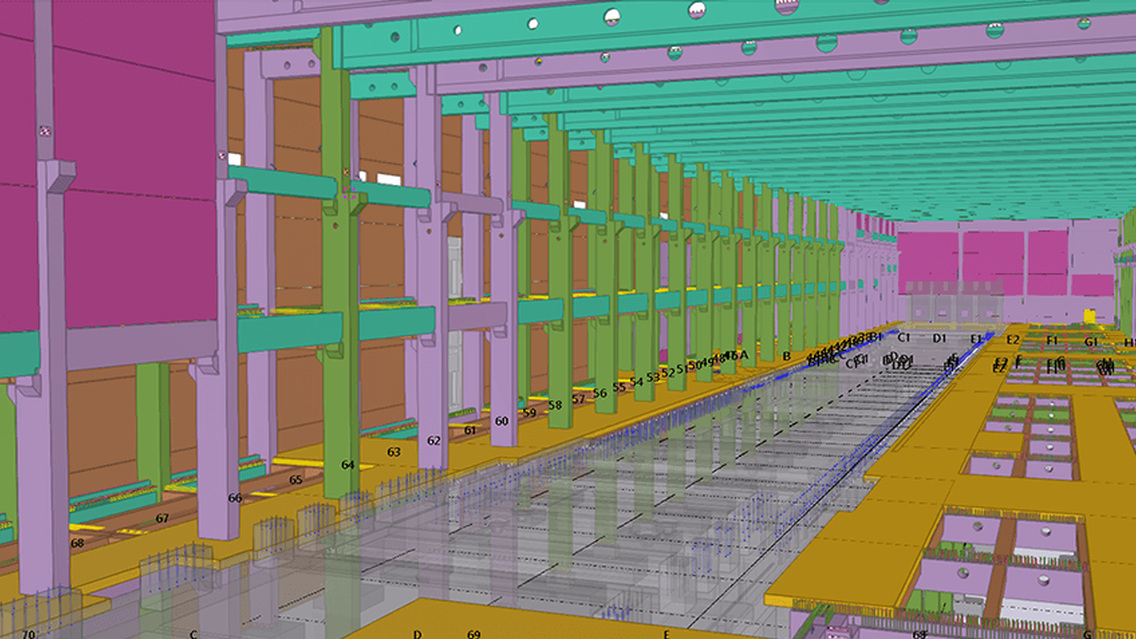

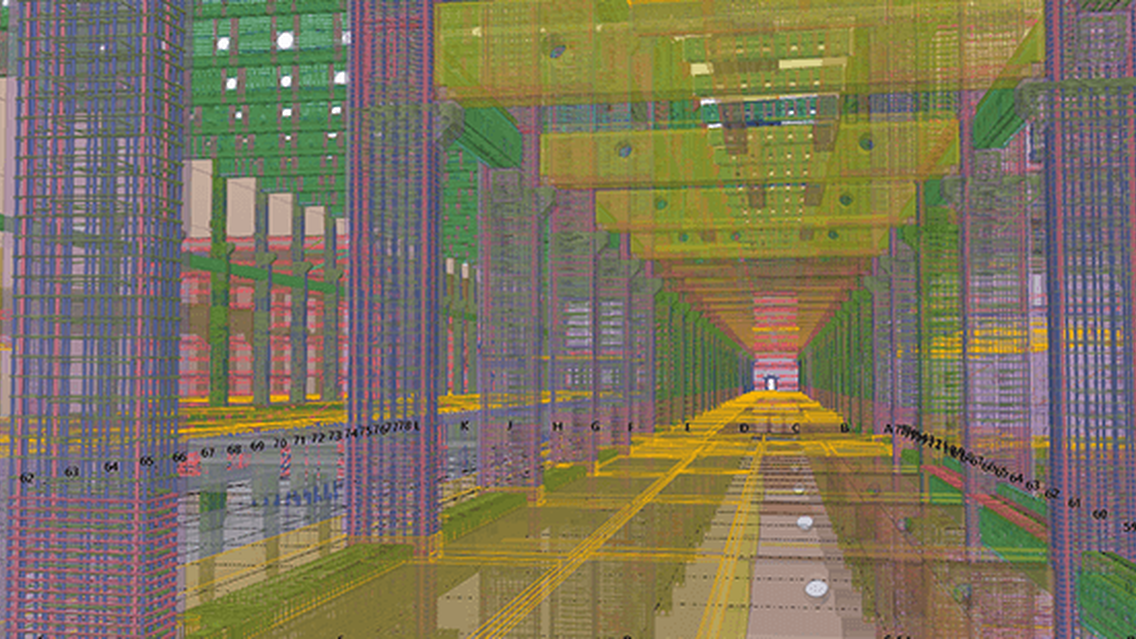

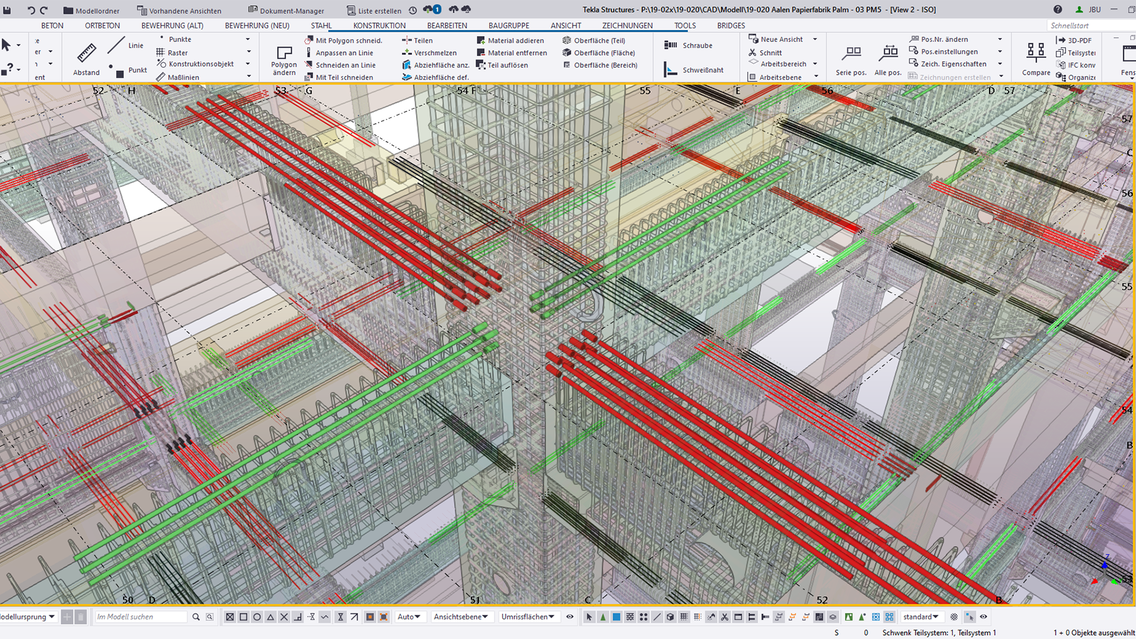

The extraordinary size of the overall project and the deadlines to be met during ongoing operations were two challenges. Additionally, the highly complex connections of the longitudinal and transverse frames, which are demanding in terms of design and detailing, are worth highlighting.

For Bau-consult Hermsdorf, the project is one of the first on this scale to be based entirely on IFC data. Cooperation with the Austrian office of BHM Ingenieure worked out very well, thanks to the exact modeling of the architectural model. In return, the data created by BCH was used for model control, clash detection and MEP, as well as for interior construction planning by BHM. The 3D model served as a basis for the coordination in video conferences.

All precast concrete elements, for which production drawings are created with Tekla, are fully reinforced in the model and provided with all embeds. A large number of possible production problems due to collisions was eliminated thanks to the detailed design of the reinforcement and embeds within Tekla. The embeds were modeled in SketchUp and are part of the BCH embed catalog, which is used across projects.

One particular challenge was to provide the team of 12 structural engineers, designers and draftsmen access to the model within a few days, due to the outbreak of the corona pandemic. The model, which was previously edited locally in multi-user mode, was quickly switched to the cloud solution Tekla Model Sharing. This enabled the employees to continuously supply data to ARGE Glass-Traub from home.