BDS VirCon, a DBM Global company, is a global Building Information Modelling, Steel Detailing and Rebar Detailing firm with a long record of iconic projects. Our vision is to be the most reputable and innovative Detailing and Building Information Modelling firm globally- the "go to" firm for large, complex projects.

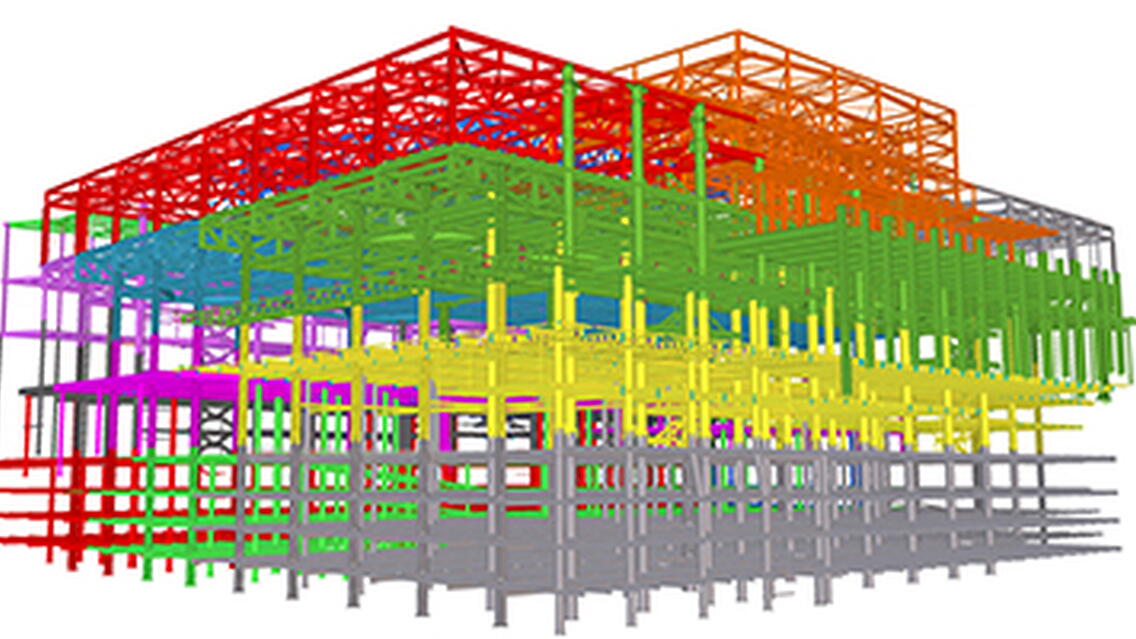

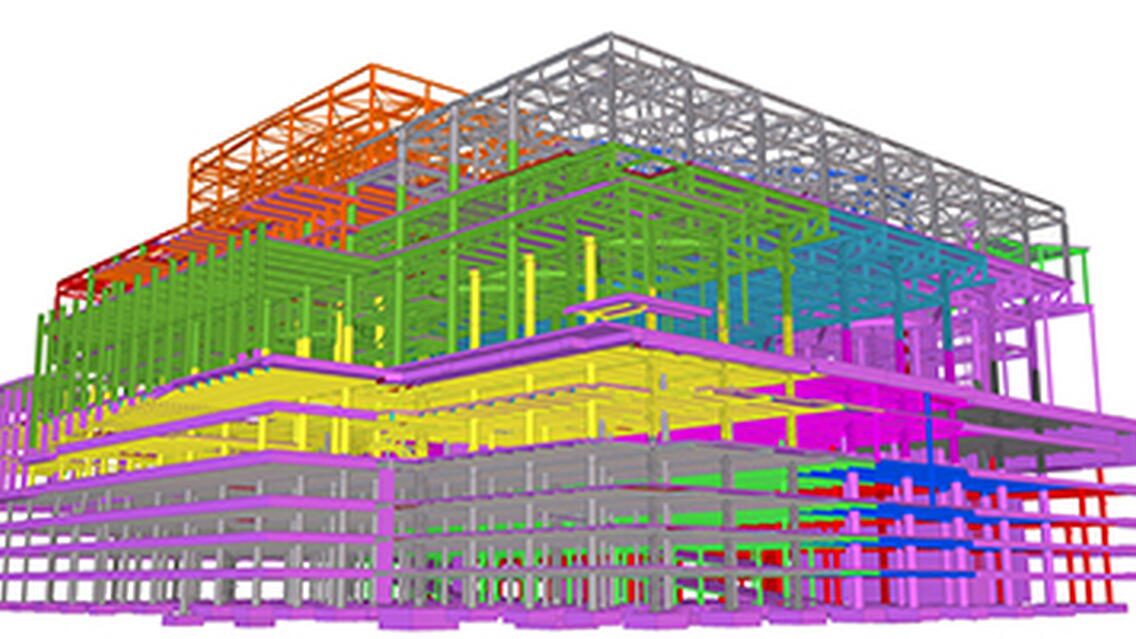

BDS was engaged in the implementation of 3D modelling and steel detailing in close collaboration with the engineering, architectural, BRB fabricators, purlin fabricators and steel fabricator for the 7800+ tonnes of steel supply.

Project Overview

- The New Zealand International Convention Centre (NZICC) is the largest purpose-built convention centre in the country

- NZICC is capable of hosting 3,150 people, with 32,500 square meters of floor space – five times larger than other convention facilities in New Zealand

- The project also includes a five-star, 300-room hotel and a laneway featuring specialty retail and signature restaurants and bars

- The NZICC has two large welcoming galleries. Both spaces will be inviting and create an impressive sense of arrival.

- The NZICC is configurable for up to 33 meeting space at any one time with additional pre-function spaces in the adjacent laneway

- The building and the façade designed with unique New Zealand identity. It is designed for a total of 1327 car parks.

- The total of 21,000m3 of concrete and 7800 tonnes of structural steel was used to construct the New Zealand International Convention Centre

- The New Zealand International Convention Centre contains 4 basement levels for car parking, Level 03 is Exhibition hall with trusses and Level 05 is theatre with low and high roof trusses

Challenges overcome:

Level 05 truss and Truss Deflection: Gusset geometry is unique and complex in Level 05 truss connections. The Primary and Secondary Trusses are connected to Cruciform columns with Star plates, CHS columns with circular flange plates. Trusses have been modelled without deflection but the incoming beam connection to truss have been modelled based on the final truss deflection at site.

BRB Coordination: BRB connections are modelled based on the BRB connection design and coordination.

Cruciform Columns: Welded plate columns with Star plate connections for Trusses.

Concrete filled CHS columns: The CHS columns were filled with concrete in Site and Filler holes were provided in the Columns

Low and High Roof trusses: Low roof and high roof trusses are modelled with purlin connections which has been coordinated with purlin manufacturer.

Plenary area: Plenary area with cranked beams has multiple points and arrived based on the concrete slope.

Project duration: Project duration is around 2 Years.

Fabricators: There are 2 Fabricators, one is Culham (NZ) and the fabrication is done in New Zealand. The other one is Thai Herrick (TH) and the fabrication is done in Thailand and erection in New Zealand.

Multiple Design changes: We had multiple design changes during the execution of the project