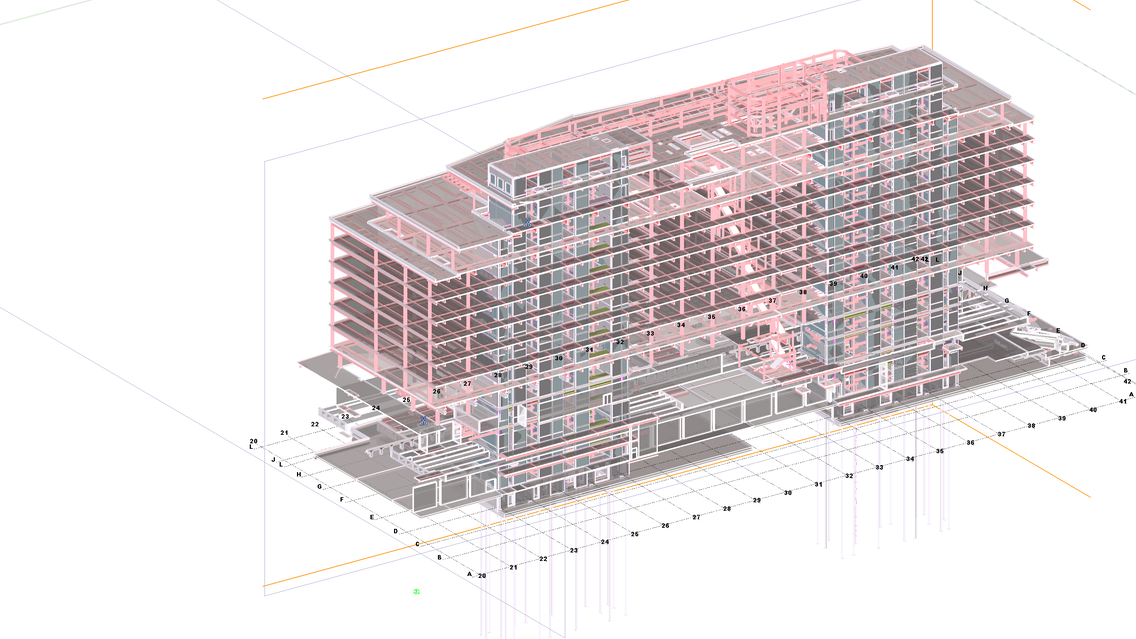

Google Headquarters project

The project involved extremely wide knowledge and skills, hardly manageable without extensive use of BIM solutions and advanced use of Tekla.

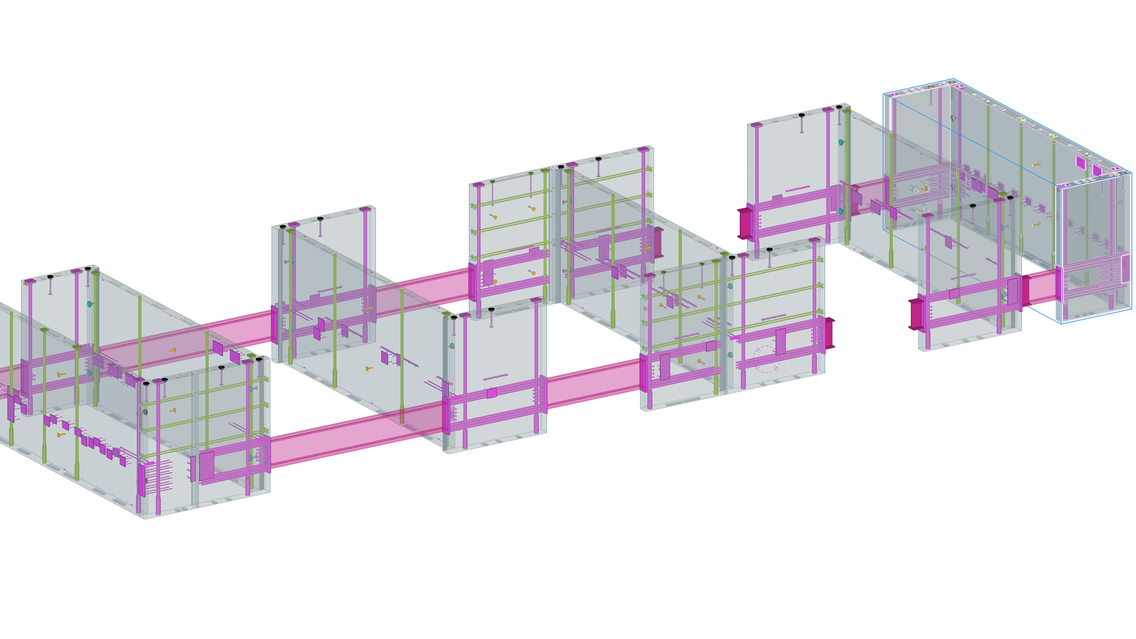

According to the initial goal, the new Google Headquarters project was characterized by the need to put together design features typical of concrete design with design features typical of steel design.

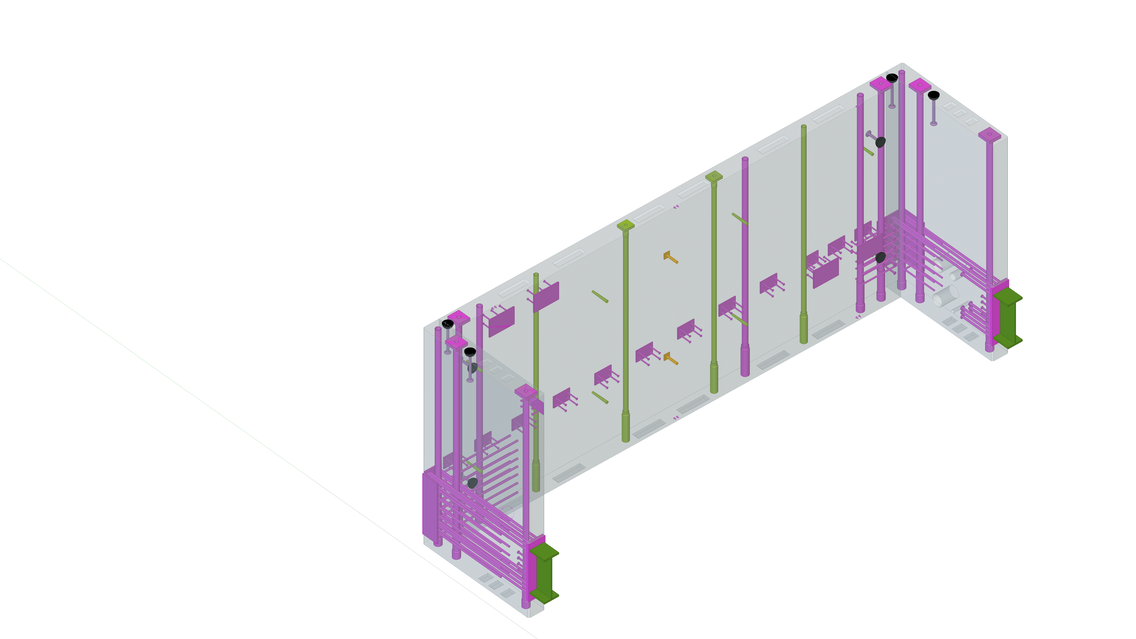

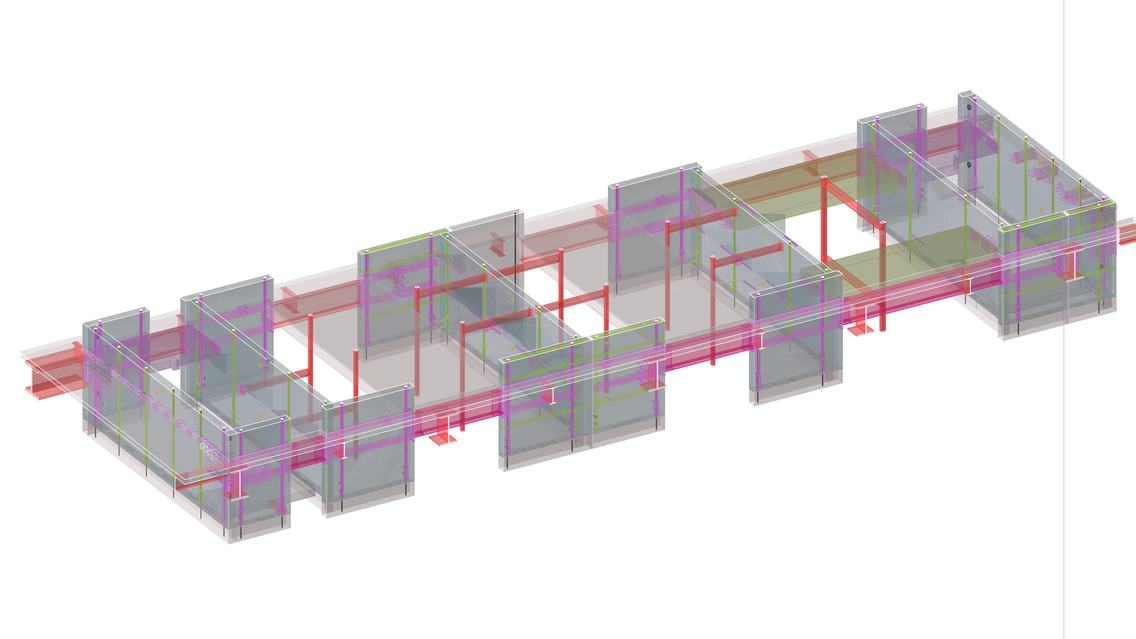

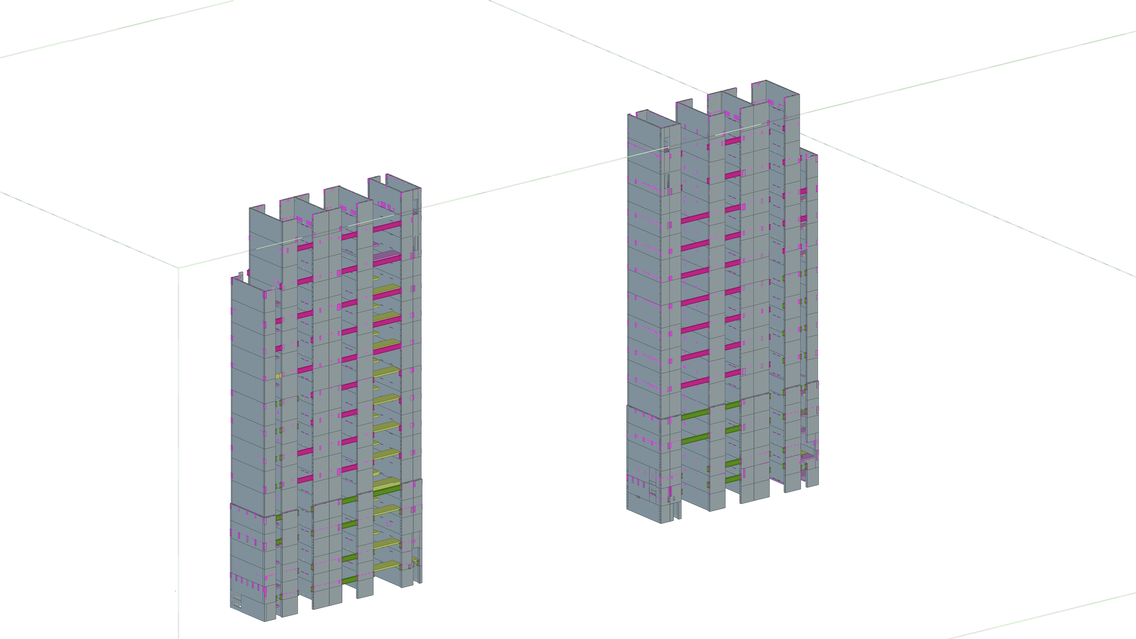

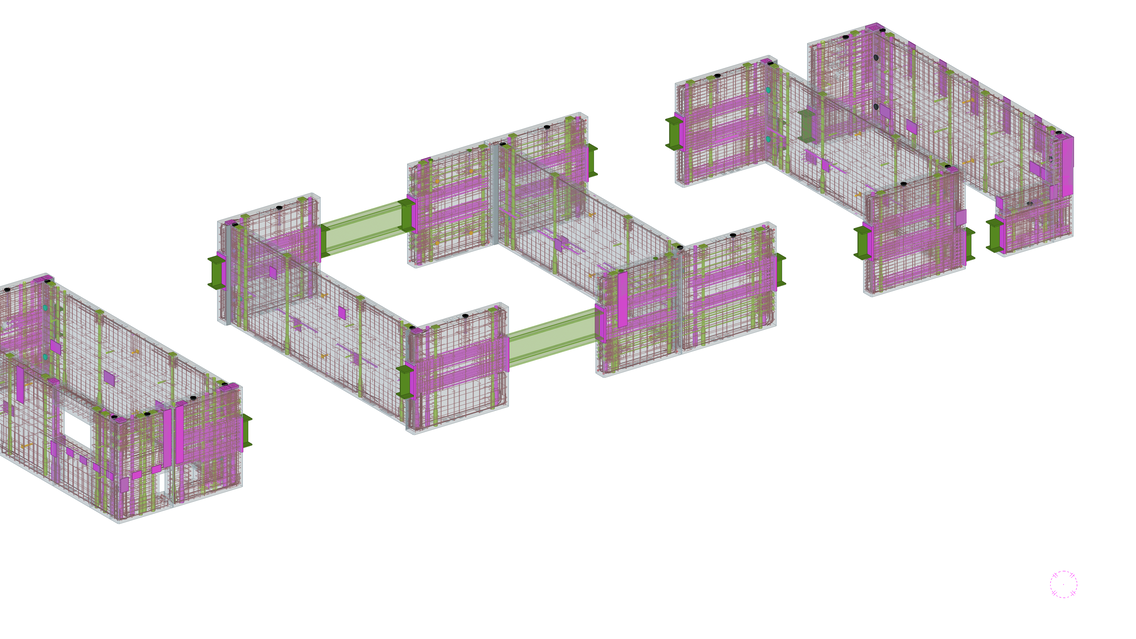

The presence of concrete post-tensioned pre-fabricated concrete cores(with segmented construction) and the need to install all connection elements to the steel structure during the prefabrication phase ( at the pre-fabrication site), highlighted the need to develop a BIM model of a concrete structure with tolerances typical of steel design.

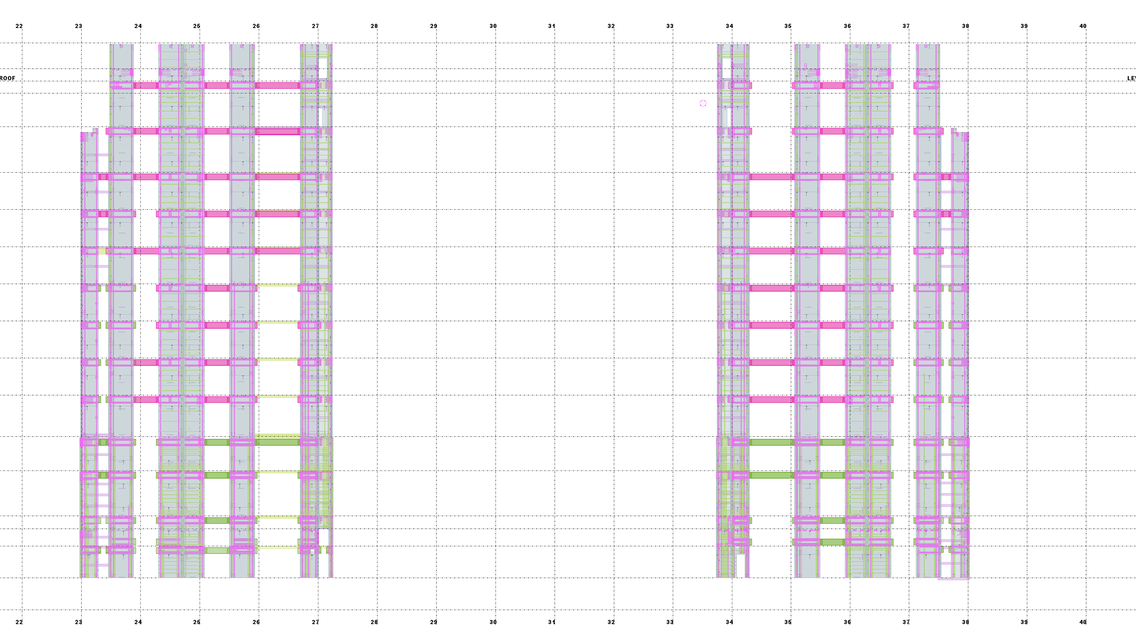

The drafting of shop drawings was developed in parallel to the development of construction engineering, this last activity affecting the definition of reinforcement and impacting on the design of many details.

During the design phases, the client pressed for a remarkable reduction of production time quantified in 30% of available days.

Production process sped up, and finally the request was fulfilled. The activity was ended in ⅔ of the initially predicted time.

This success was largely made possible by a remarkable increase in human resources but also thanks to an advanced use of Tekla.

298 different pre-cast concrete core elements with high variability in terms of steel connections and inserts were developed, with full traceability of all construction elements. Shop drawings and construction engineering took 8 months to complete.

What were the challenges and what made the project successful?

- Design a concrete structure with the typical tolerances and skills of steel structures

- Reduce the production time and end design activity with a 30% reduced available time than initially planned.

- Careful activity of project management, quality assurance procedures and advance use of Tekla led to a successful outcome of the activity

What are you most proud about the project?

The overall high quality of the product associated with an extremely limited production time and the need to reduce the submission schedule of 30% with the activity already planned and initiated. This made us extremely proud of the final, positive result.

What benefits utilizing BIM and Tekla software brought to the project?

Extreme flexibility, full traceability and fully-integrated design with the presence of transversal skills, expertise and knowledge.

Project in numbers

- Overall building dimensions: 155x78x75 meters

- Number of precast segments: 298

- Execution time: 8 months

- Total no. of drawings: 3000