Mansikkala School is the largest wooden school building in Finland

Mansikkala School is part of a larger school-network reform by the City of Imatra in Eastern Finland, as a result of which the smaller local schools are centralized onto three campuses. The multipurpose building concept and wood as the building material represent climate action by the City of Imatra. The building’s frame and facade were designed modular to improve modifiability and to extend the building’s use and life cycle. The building has been handed over to the user, and the school has provided modern premises to 1,350 pupils since the autumn of 2020.

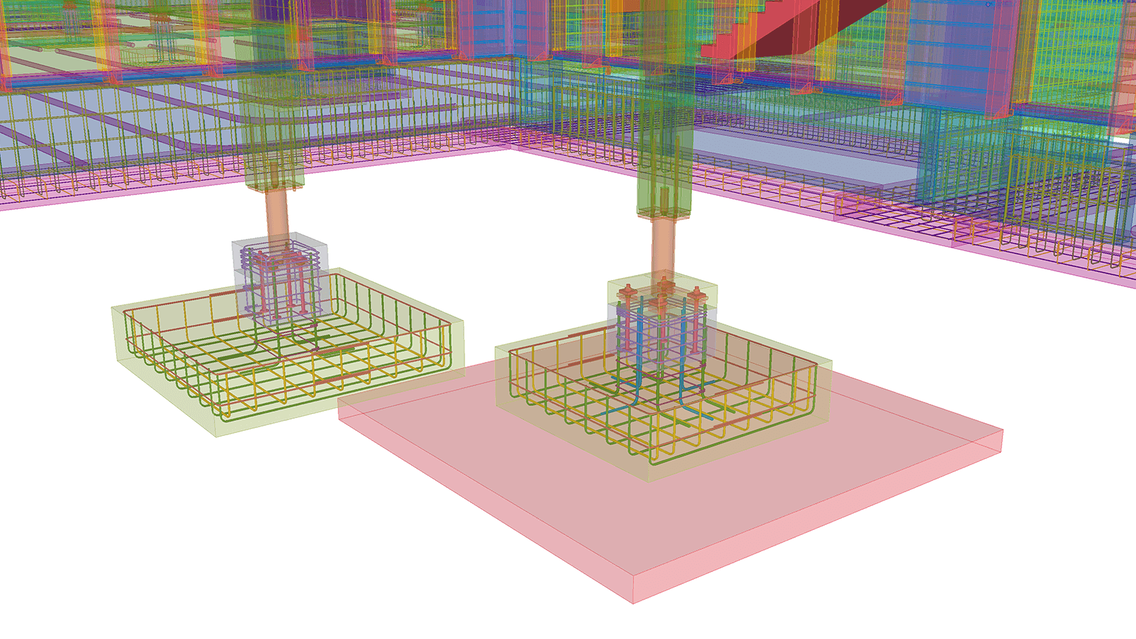

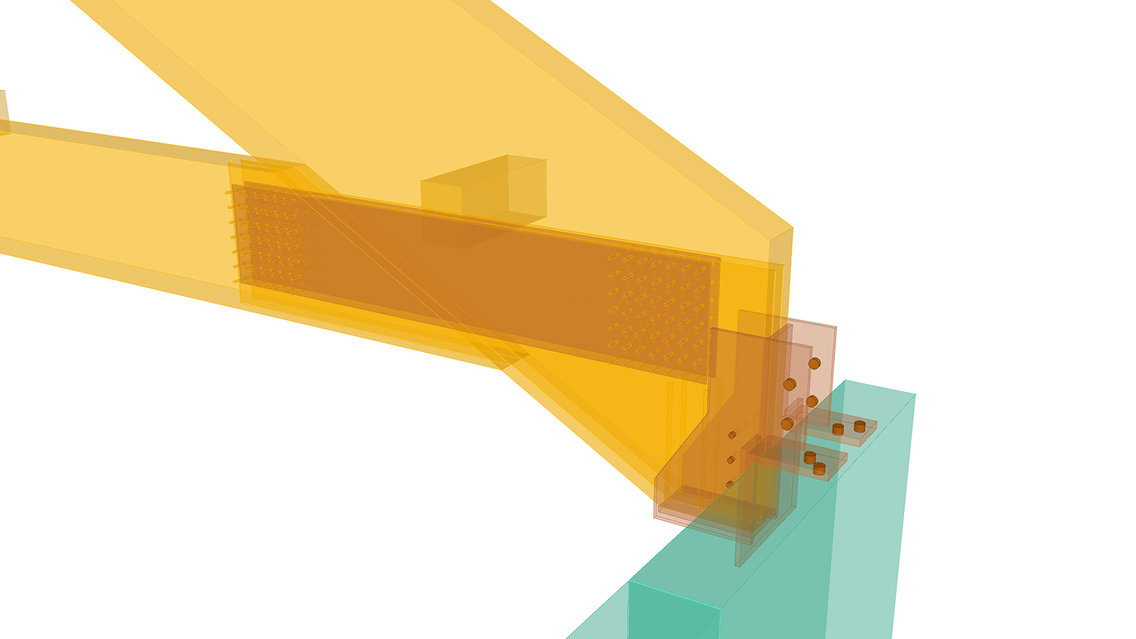

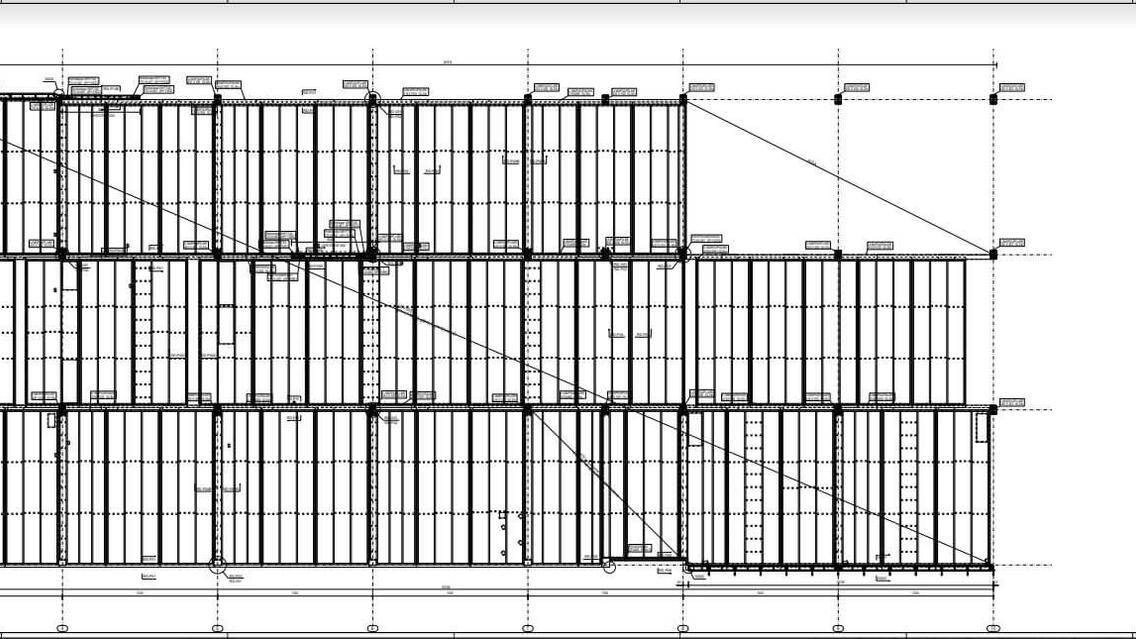

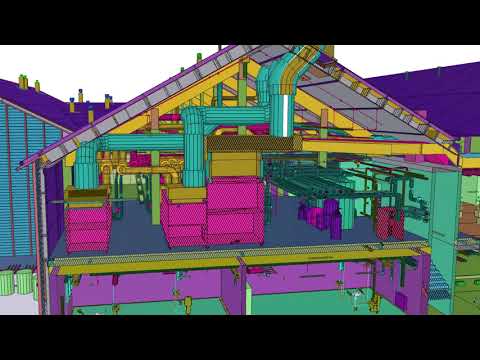

With two floors, the building encompasses a gross area of ca. 15,300 m2. Its structural system is a column and beam frame, and it also features load-bearing exterior walls and stiffening partition walls. The columns and beams are made of glulam, the facades of wood-framed wall units, the intermediate floors of LVL rib panels, and the roof of nail plate trusses. The building’s modular division is 7.2 m in both directions i.e. a “supergrid”. Design was based on this modular division which also steered the structural and prefabrication design of the building. Sweco Rakennetekniikka Oy delivered the conceptual and principal structural design and prefabrication design for this project.

The project was a unique experience for all parties, both in terms of implementation and scope. It was carried out as a “life cycle contract,” which means that the contractor is responsible for both the design assignments and the maintenance of the building for the first 20 years of its life cycle. Life cycle was in focus during the design process, too, in creating flexibly modifiable premises with the help of a simple module structure and modular load-bearing units. The scale and type of the project meant there were more design tasks and technical requirements to manage.

During the most critical phases of the project, the design team was fairly large and structural design was done in three different locations. Several major changes were made in the design phase, and implementing them required careful coordination. Constant communication and close cooperation were key in change management and overall project coordination. Cooperation with contractor YIT and supplier Oiva Wood was easy thanks to existing relations from previous wood construction projects.

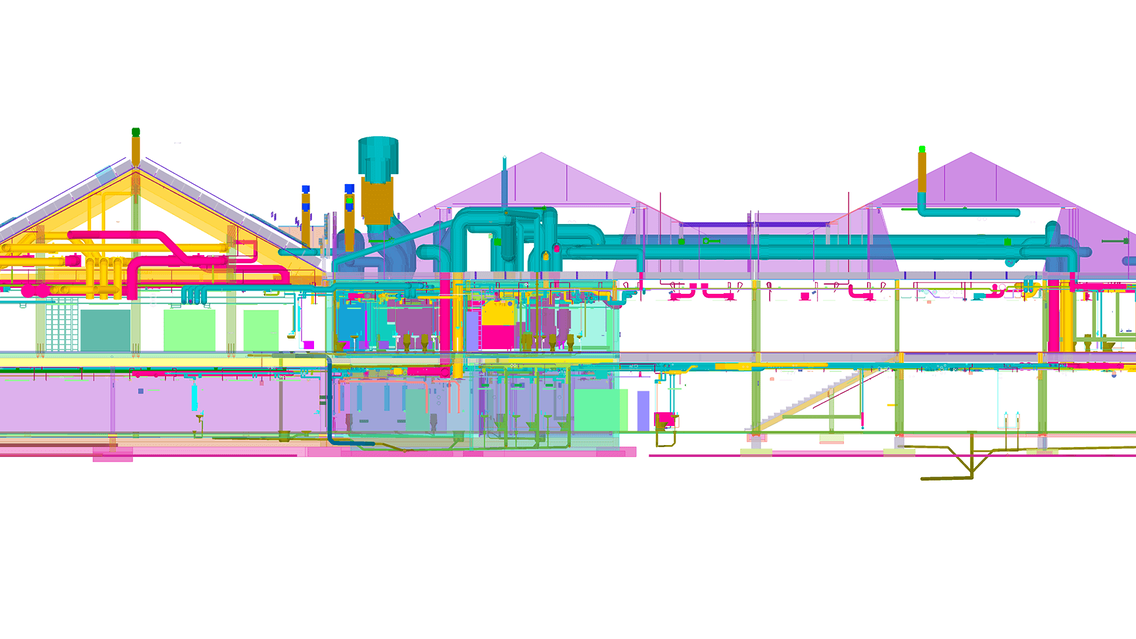

BIM proved a critical tool in MEP and structural coordination

Due to the large amount of MEP engineering in the building and the modular structure that required precision, coordination was critical to the success of construction. Modeling with Tekla Structures and using the model effectively helped the teams to succeed at both the factory and on the construction site. Wood elements require extreme precision, but despite the strict dimensional tolerances, frame installation proceeded as expected. Production and installation errors were minimized by reviewing the 3D designs in both IFC format and in the Sweco Smart Drawings service. The construction phase was expedited, for example, by assembling the trusses into larger modules in advance.

Structural design was carried out based on BIM. Structural and fabrication drawings as well as a significant number of reports for procurement and construction were output from the model. The models formed a design coordination platform for the project. Coordination of such a large project would have been close to impossible without accurate, high-quality building information models from the various design disciplines. Precise modeling enabled fluent prefabrication design and installation on site in a large project. Each element and connection were modeled at the agreed level of detail so that there were no confusion or surprises on site.

The design teams delivered IFC models for reference for fabrication planning and installation, too. Sweco’s custom components were used in the wall units and connections. 3D geometry was transferred from Tekla Structures to RFEM by using export plugins and software interfaces. The client received both the drawings and the building information model of the project. The number of RFIs was reduced by updating the IFC combination model regularly; the models were more or less updated every two weeks. The architect submitted an IFC model to the structural design team, and it was imported to Tekla Structures for reference. The architect communicated changes by email and by adding notes in the drawings.

Project parties:

Structural design: Sweco Rakennetekniikka Oy

Architectural design: ARK Perko Oy

Client: Imatran kaupunki

Contractor: YIT Talo Oy

HVAC design: Granlund Oy

Electrical design: Granlund Oy

Sprinkler design: Granlund OY

Acoustic design: A-Insinöörit Suunnittelu Oy

Geo-technical design: Ramboll Oy

Fire consult: L2 Paloturvallisuus Oy

LEED consult: Green Building Partners Oy