SIEMENS trusted us to manufacture and assemble phase 1 of the Mallorca Airport expansion. Due to the good results of our work, we were also awarded phase 2, and we hope that next year we will also be assigned phase 3.

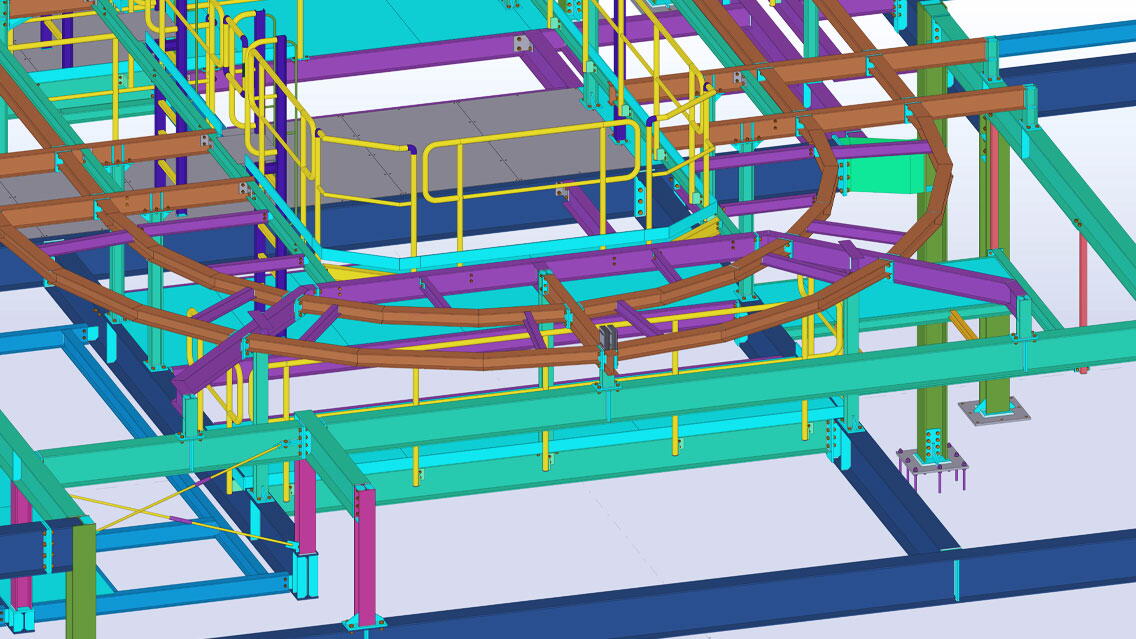

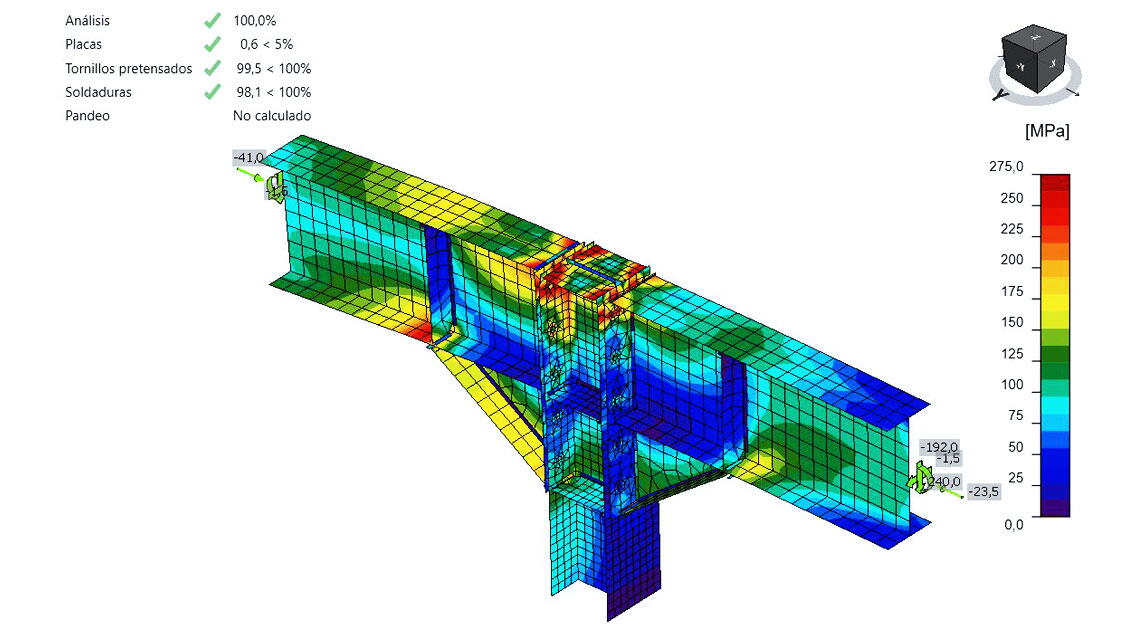

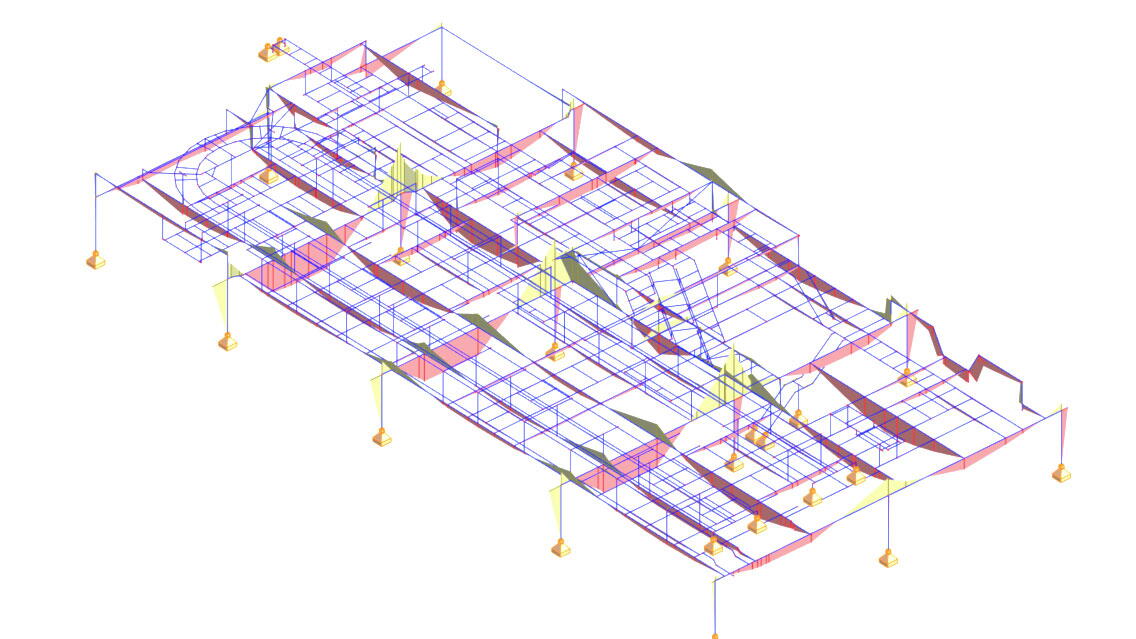

In the first engineering phase, SIEMENS combined the works of stakeout in situ and point cloud analysis to later calculate it (SW calculation + Idea Statica) and design it in 3D. The platforms had to support all the conveyors and other specific equipment.

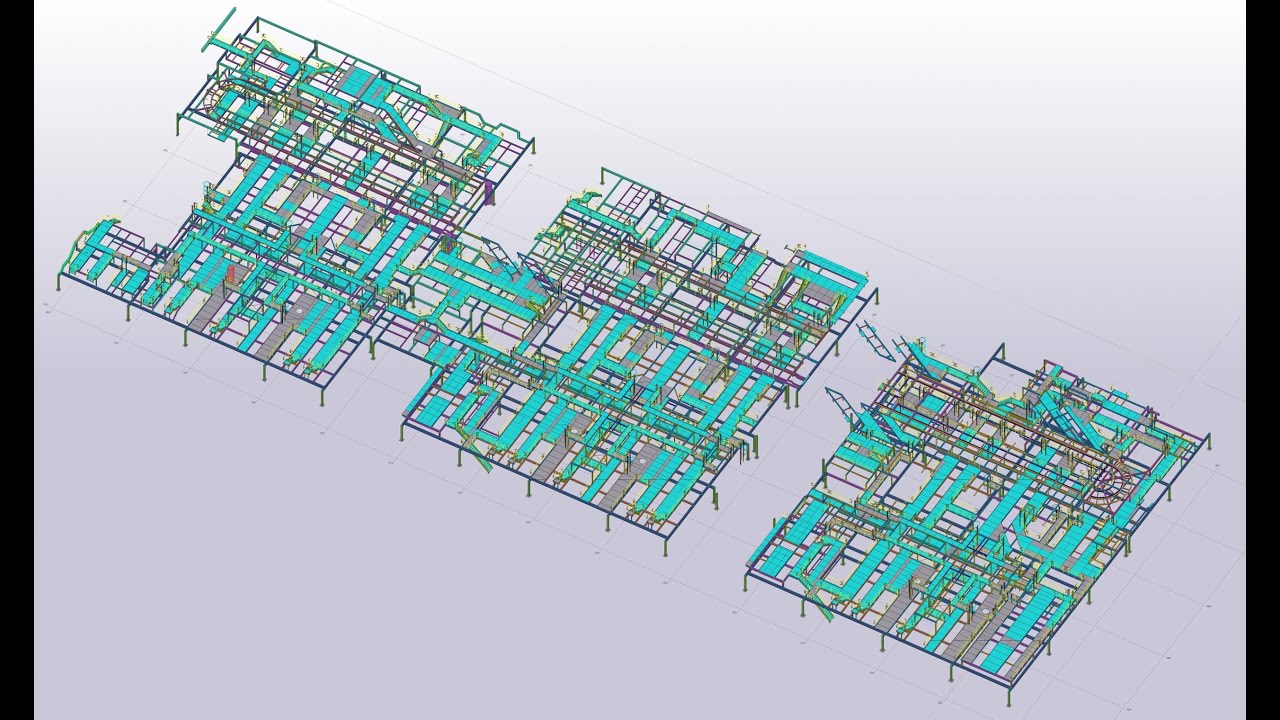

The second engineering phase consisted of Tekla modeling, fabrication and assembly drawings, the actual fabrication, and on-site assembly tasks were performed by Entrerrios Servicios Generales.

There were 600 tons of steel, 2110 m2 of the floor plate, 2060 ml of handrails, 41 stairs, 112 cat stairs with their respective doors, and 280 m2 of Tramex.

Everything was modeled in a single model, where the best Tekla tools were used.

Reference models: having the client's layout with the location of their equipment made checking collisions, interferences, accessing problems, etc., very easy.

Standard parts model: before starting, all typical connections were defined.

Auto join: all the components were defined. When the rules are created in this way, the modeling is very fast, and errors are minimized.

Model Sharing: part of this project ran at the pandemic's peak, so we had to work from home. We were surprised by how well this new feature worked.

Trimble Connect: a great tool to coordinate and work with everyone involved in the project.