London 2012 Olympic and Paralympic stadium transformed for the future

Innovative design and engineering have helped to transform the former Olympic Stadium into a world-class permanent, multi-use venue for football, athletics and concerts, with original components added, replaced, reused.

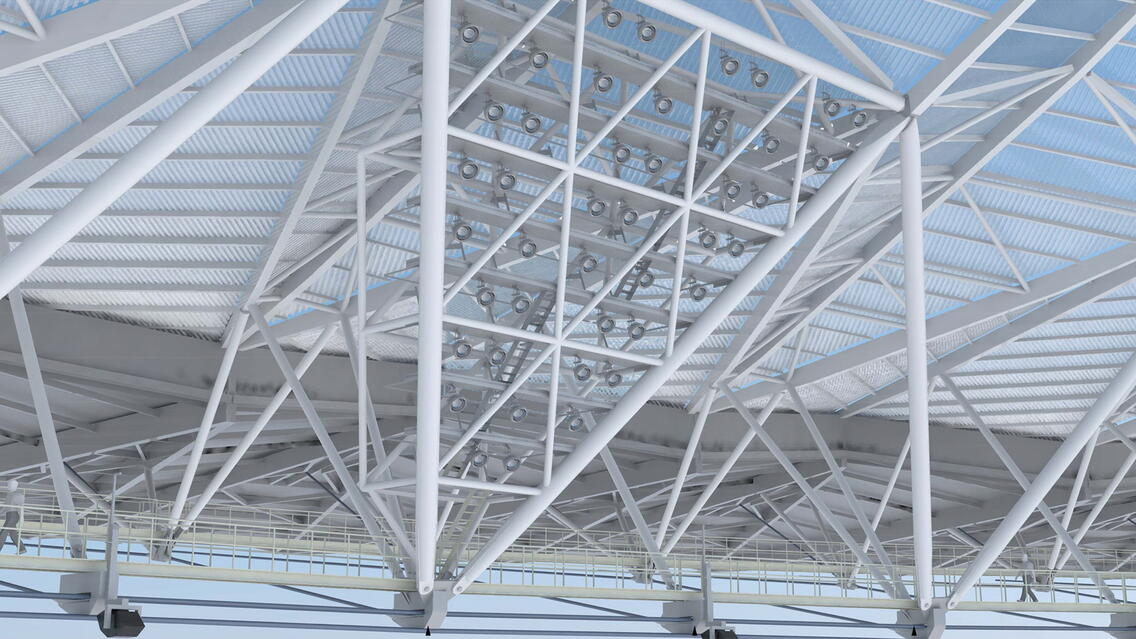

The main change to the stadium was its new cantilever roof - the largest spanning tensile roof in the world. At 45,000m2 and 84 meter maximum span, it is nearly six times the weight of its predecessor.

The roof profile was designed to improve acoustics and heighten the spectator experience, focusing sound and projecting it towards the pitch, all while reducing noise for the surrounding residential areas. Due to the very long spans and weight restrictions, steel was the only viable construction solution.

The architectural legacy

When Populous designed the stadium, it did so with an ethos of ‘embracing the temporary’ in the knowledge that, post-Games, the stadium’s function would change and its structure would too. To preserve some of its identity, the iconic triangular lighting tower design that stood over the old roof has been inverted and now hangs underneath the new larger roof.

One of the main stipulations was to retain the running track. To prevent this from adversely affecting the atmosphere at football matches, a retractable seating system was included in the new design. All four sides of the lower bowl are able to move over the running track when in football mode and, meeting UEFA rules, the roof extends fully over the retractable seating.

Complex strengthening works

Work began in late 2013. The existing structure had to accommodate far greater loads than originally designed for. The new structure included 8km of steel cables weighing 930 tonnes, 112 steel rafters, 2,308 purlins, 422 struts, 9,900 roof panels and 14 light paddles each weighing 43 tonnes, with the whole structure weighing in at around 4,700 tonnes.

Early works involved the de-construction of the old roof and the strengthening of the existing structure, foundations, V-columns and the perimeter compression truss. The strengthening work was one of the major challenges for William Hare. It was necessary to replace and/or strengthen the existing V-columns with significant strengthening works to the existing compression truss. For this alone, the amount of hierarchical complex calculations involved William Hare developing its own in-house software to process over 10,000 calculations, a task that would have been impossible using traditional methods.

Fabricating and installing the new roof

The 14 new lighting paddles are positioned beneath the new roof. Each houses up to 41 lamps, many of which are the original stadium lamps. Four 600 tonne capacity cranes operated in tandem to lift the lighting paddles and the other roof members into position.

The tolerance in the fabrication and quality of finish was expected to be very high and was designed with security in mind. With complex geometry, William Hare manufactured specialized jigs to fabricate some of the complex tubular nodes. A total station was employed to set out all of the lighting paddle’s brackets, which lean towards the pitch and are slanted in three opposing planes. Not least, the oval shape of the stadium and the movement and tolerance requirements only gave the opportunity for single pieces to be replicated twice; this meant that half of the stadium structure was fabricated with unique members.

Following the V-column and compression truss strengthening work, to maintain equilibrium until the oval was fully formed, the erectors worked in two teams at opposite ends of the stadium, working in a clockwise rotation constructing the back roof first, then the front roof complete with the lighting paddles and walkways.

To ensure the correct distribution of forces through the cable support structure to the compression truss, the front and back roof are completely independent of each another. However, for the installation of the lighting paddles, the front roof had to be temporarily tied to the back roof to ensure that they did not overturn until the full ring stiffness of a complete oval was achieved.

BIM modelling - key to project success

4D Programming via BIM modelling was the key to delivering this successful project to a very high profile deadline, which was originally the Rugby World Cup 2015, in September 2015. However this was brought forward to fit in the Sainsbury’s Anniversary Games, in July 2015. This meant that all major construction had to be complete by May 2015.

London legacy now a reality

The future of the venue is now secure; and it is set to become the new national competition center for UK Athletics. The stadium has also been upgraded to a 54,000 all-seater UEFA category four football stadium, the highest category of football stadium in the world, and is the new home of West Ham United football club from the 2016/17 season onwards.

The legacy of the London 2012 Games is transforming and integrating one of the most challenged areas in the UK into world-class, sustainable and thriving neighborhoods. A dynamic new heart of east London is being created which will be an inclusive community, a thriving business zone and a must-see destination where people will chose to live, work and play and return time and time again.