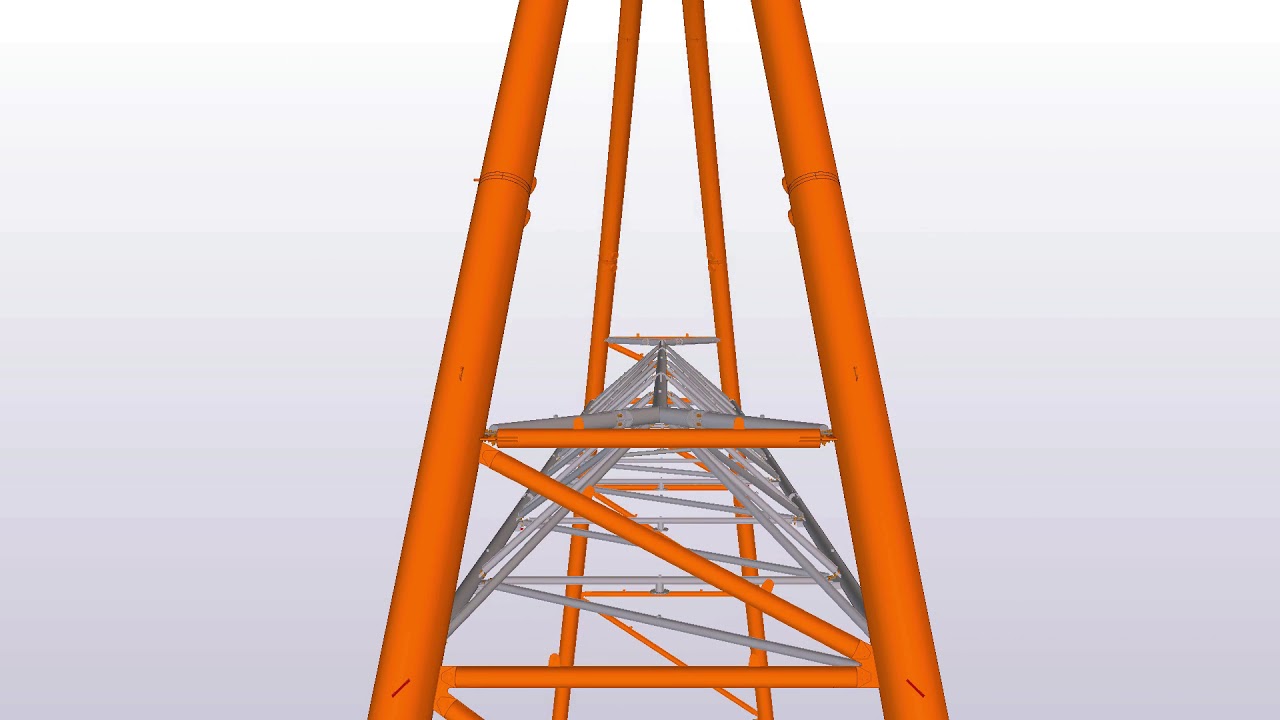

An arched landmark of recycled steel pipe

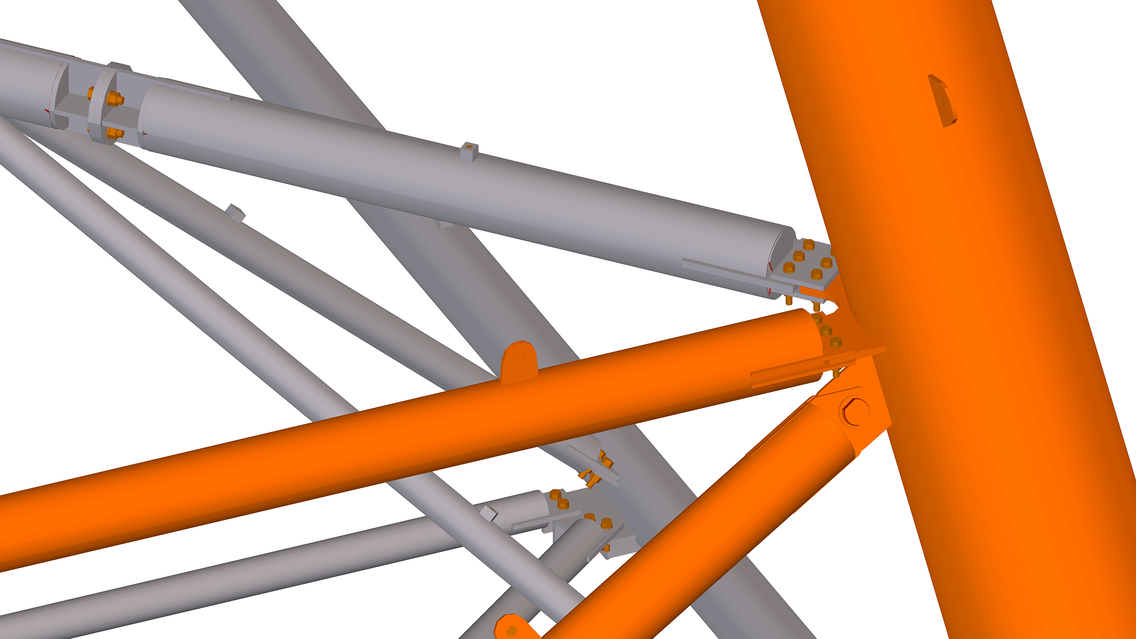

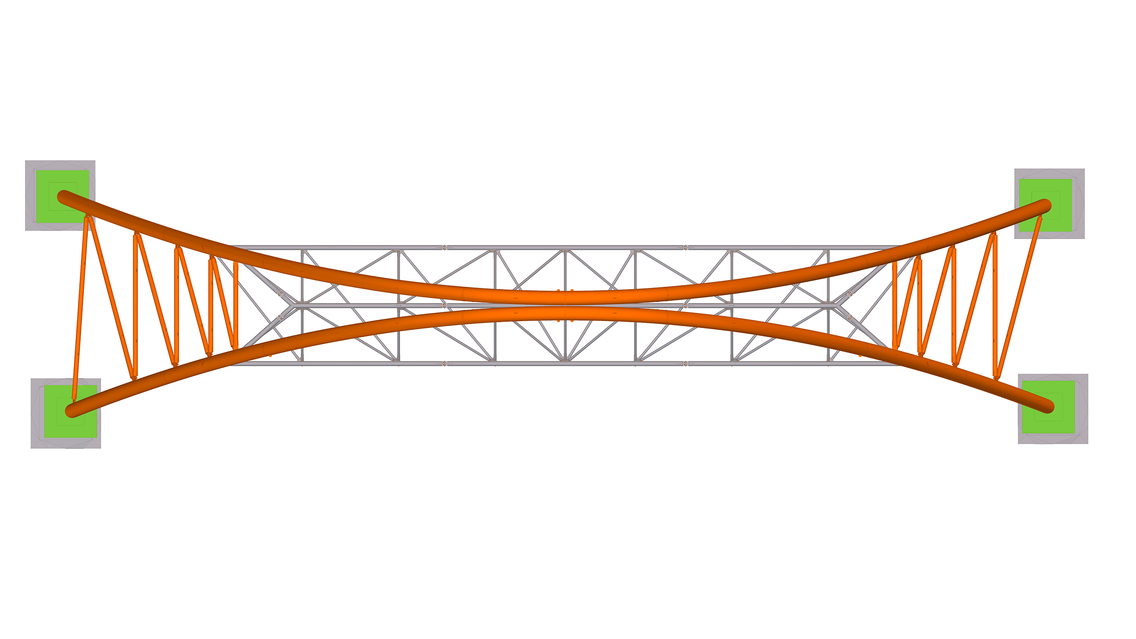

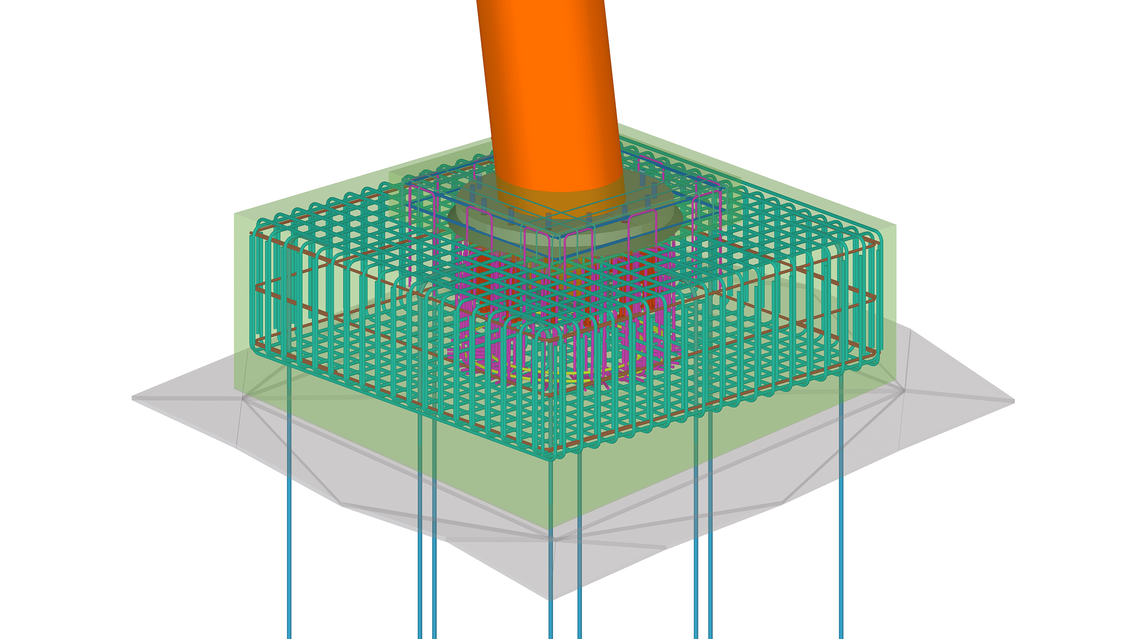

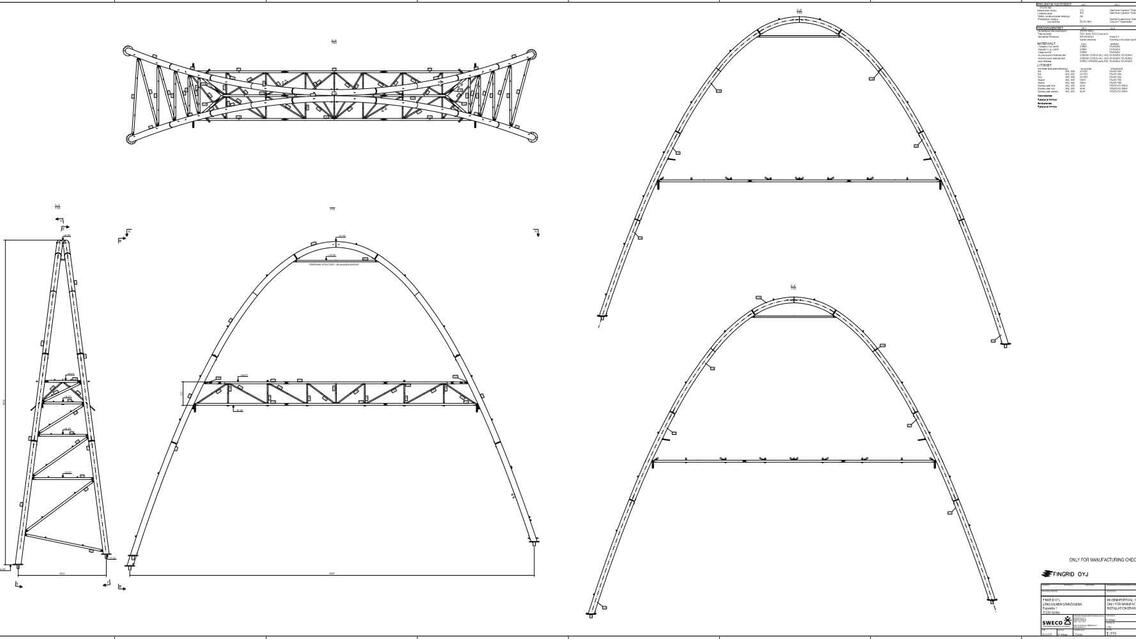

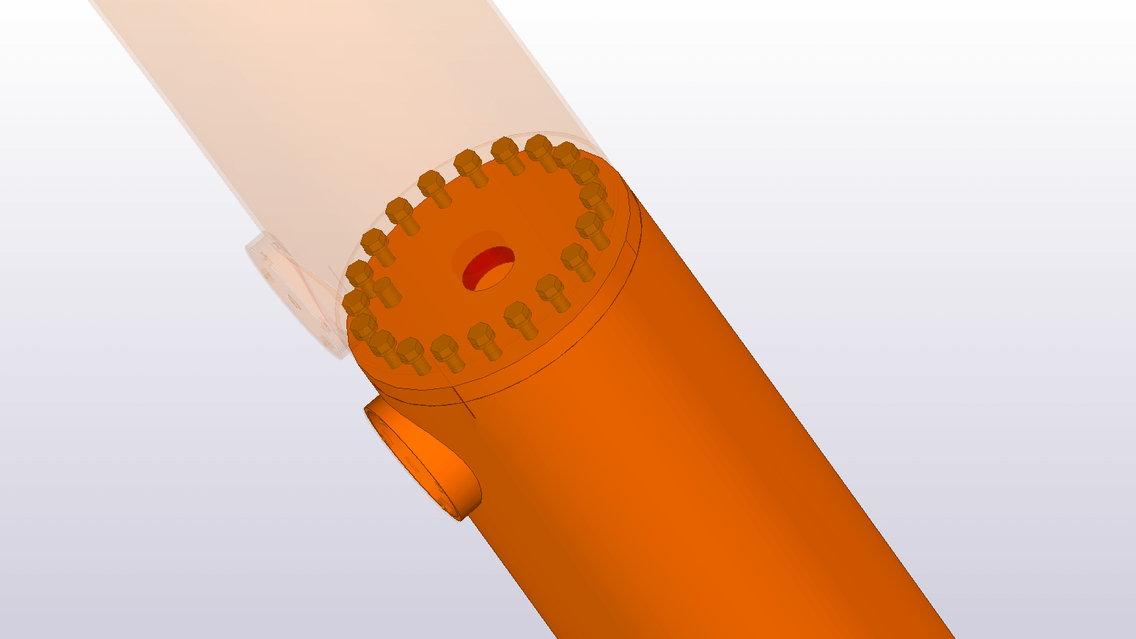

The project is an electricity distribution substation that serves the residents of Helsinki and Vantaa in the Finnish metropolitan area. With a capacity of 800 MW, it can cover all the power supply needs of the area. Electricity is led from a 400 kV main grid to the substation via the 50 m tall portal. The portal consists of 14 pipes of 800 mm in diameter and a horizontal truss which supports the power cables. The pipes have been connected by bolting. Manufacturing of the portal started in the summer of 2017, and it was put into use in the beginning of 2018. Sweco Rakennetekniikka was in charge of the structural design and detailing.

The weight of the 57-meter wide and nearly as tall structure is 100 tons. Its arcs are made of weatherproof COR-TEN steel, and the horizontal truss is made of hot-dip galvanized steel. The parts are connected by stainless steel bolts, so there was no need for welding on site. The COR-TEN sheets were rolled in Poland, from where they were taken to Italy to be formed to pipes. After this the pipes were bent into arcs in England. The welding of plates and accessories was done in Estonia, after which the assemblies ready for installation were transported to Finland.

Handling the geometry of the bent pipes turned out to be the biggest challenge of the project. BIM-based design enabled an effective design process, during which it was possible to simultaneously review various design alternatives. This ensured technical strength, feasibility and constructability to the high degree of quality set for the project.

BIM revealed a geometrical deviation in the structure

Quality control was a major challenge during steel fabrication. The model was updated with layout points to make fabrication and dimension control easier. However, the biggest challenge of the project was met at erection. Despite careful dimension control, some of the pipes deviated from the design, which led to design revisions. Due to the complex geometry, the fabricated steel pipes were laser-scanned, which enabled the as-built arc geometry to be imported into the Tekla model as an IFC reference. This turned out to be the only way to find the geometric deviations and to design the necessary fixes. Without BIM-based design and Tekla Structures, it would have been nearly impossible to find the deviations.

Model-based design enabled cost-efficient structural solutions and effective quality control. The workshop was able to utilize BIM in fabrication and quality control. Model-based design process allowed seamless and efficient collaboration between the various project parties. Thanks to modeling, its was possible to fix the parts that were not within the fabrication tolerances.

The project used Sweco’s own Tekla Structures environment. Structural analyses and calculations used links to RFEM and Ansys software. Tight collaboration between the project parties reduced the number of RFIs (Requests for Information), and model-based design ensured cost-efficient solutions. The project has won The “Kehäkukka” (Eng. “The Marigold”) award in 2018, the architectural prize of the City of Vantaa.

Project parties

Structural design and detailing: Sweco Rakennetekniikka Oy

Contractor: Empower Oyj