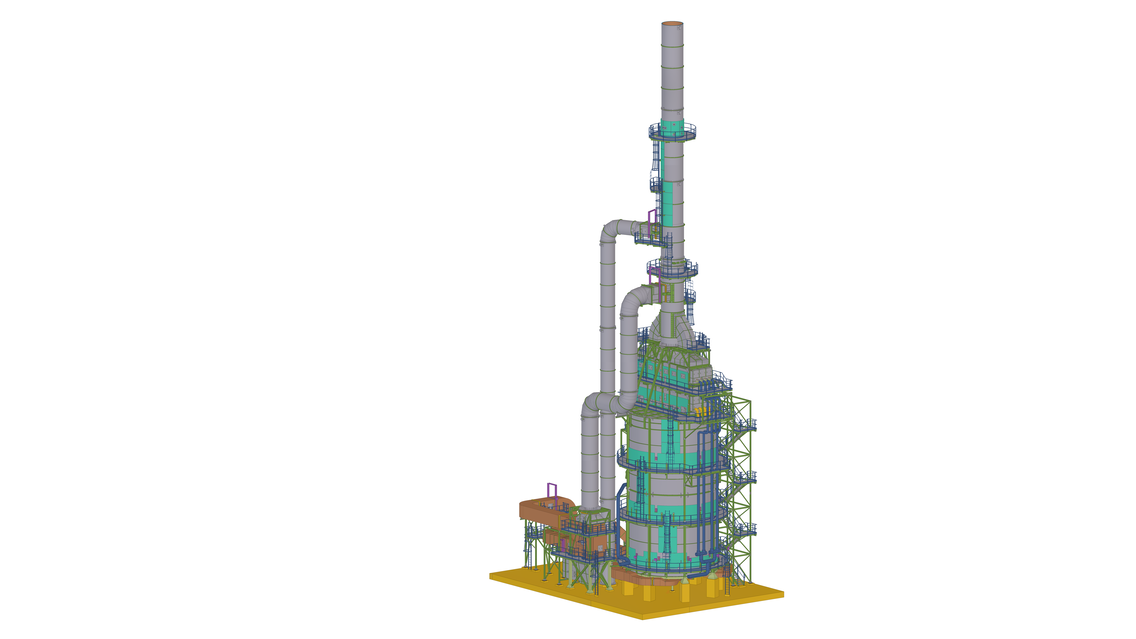

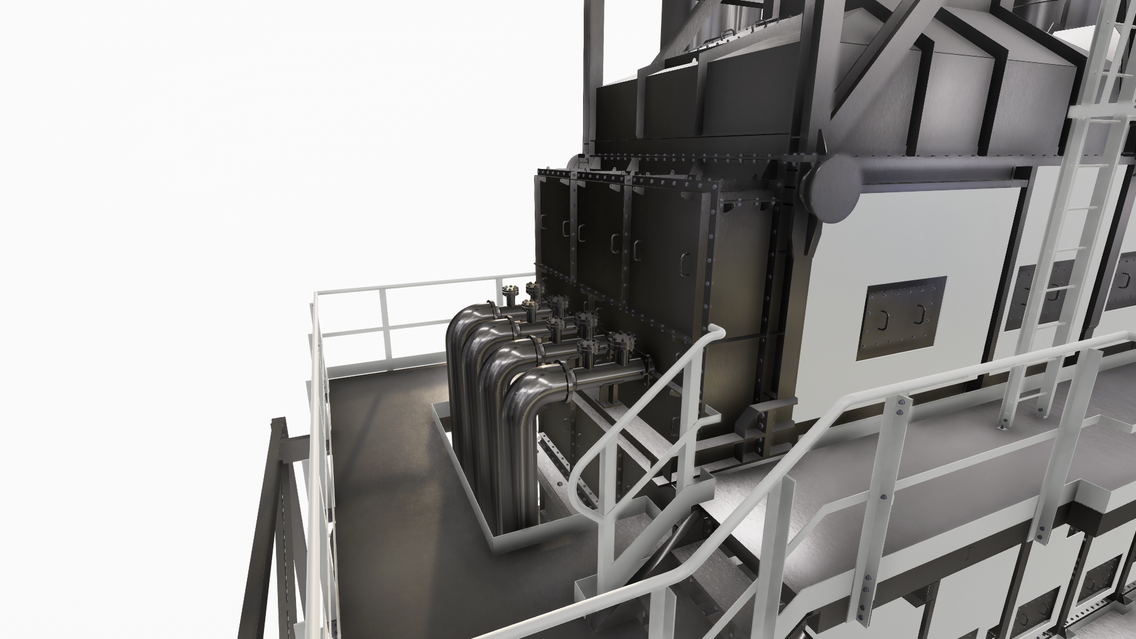

Hot oil heater

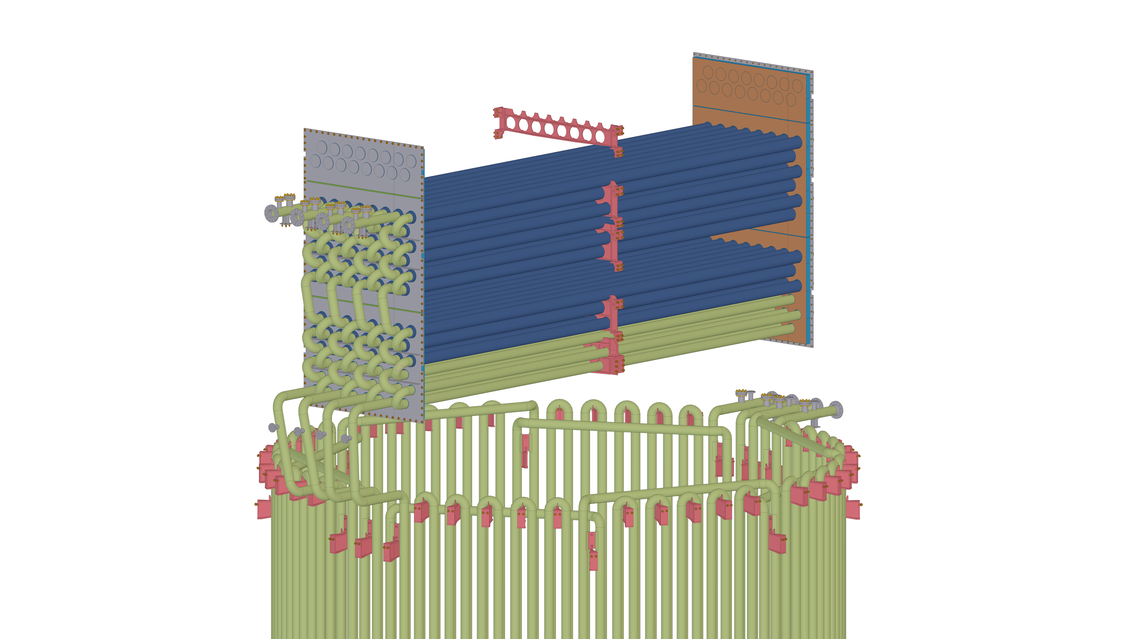

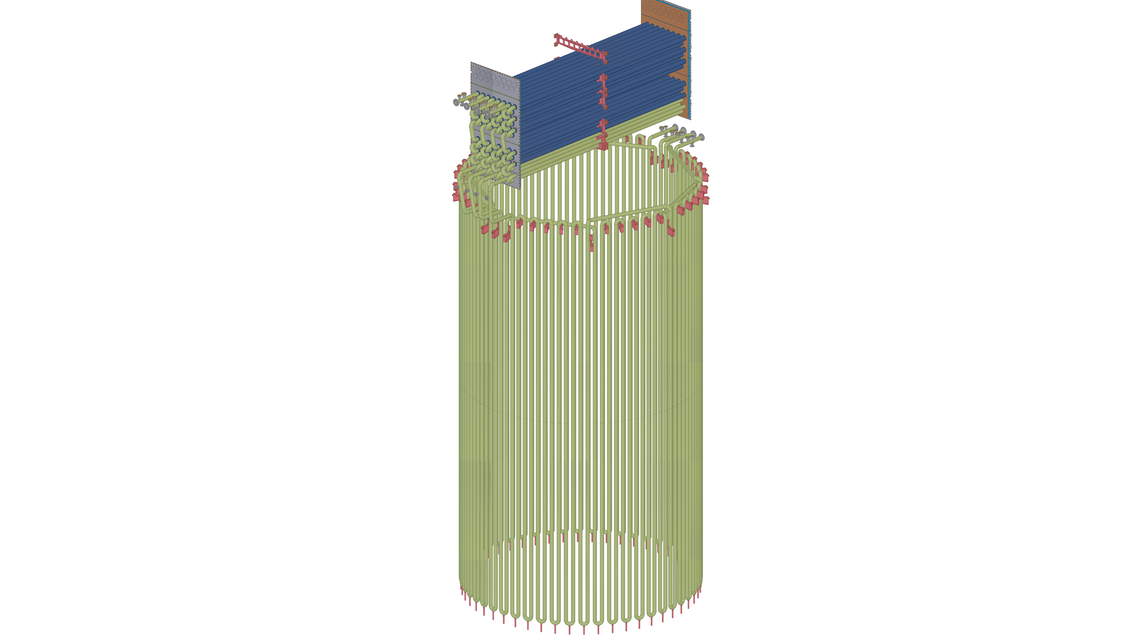

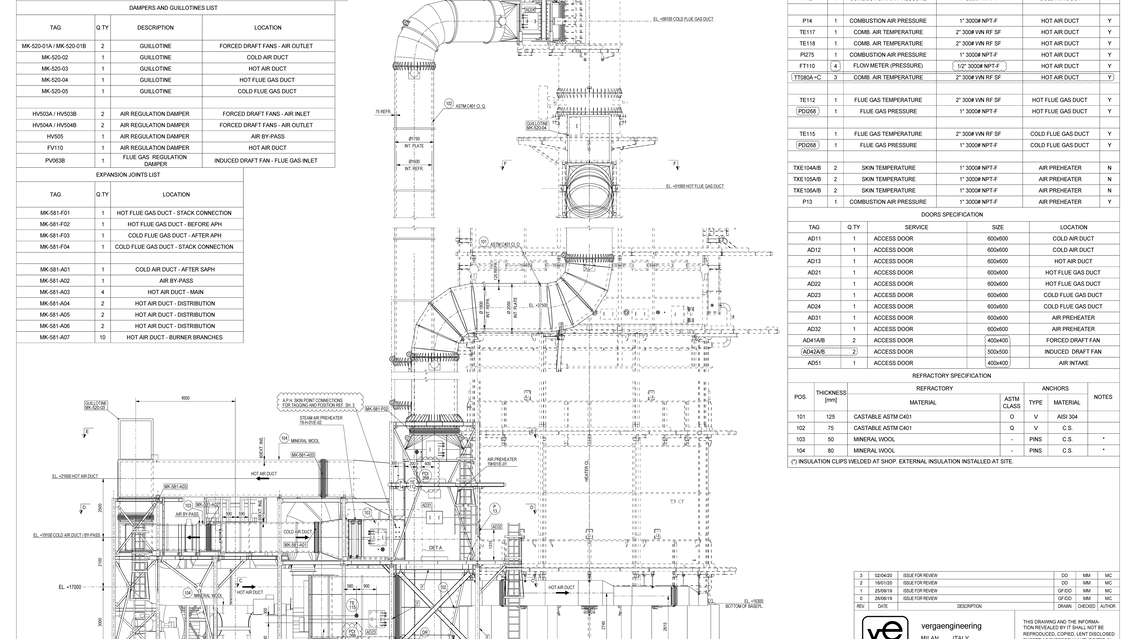

Complete development of engineering of the heater, with its air preheating system and all platforms and auxiliary support structures.

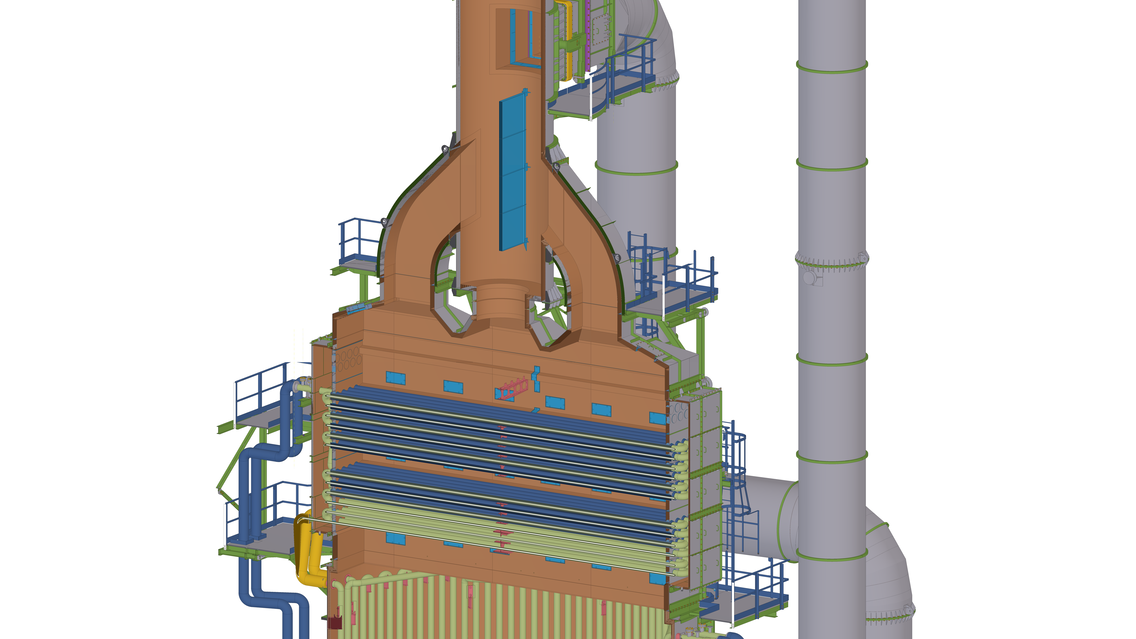

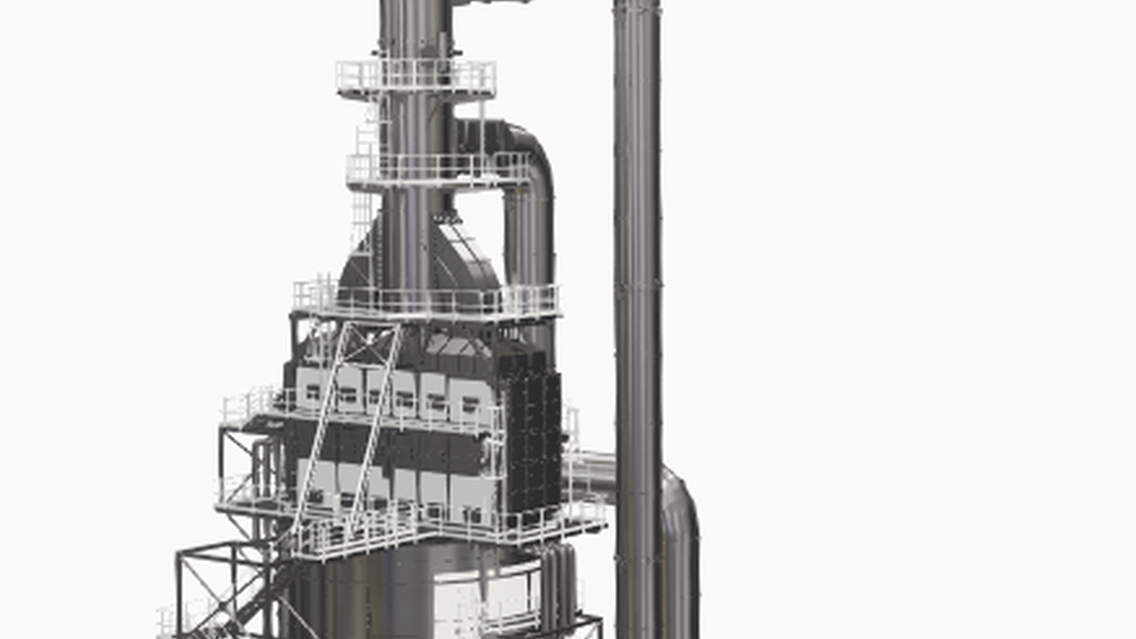

The project is relevant to the supply and fabrication of a process heater with a relevant combustion air preheating system for the MIDOR(Middle east oil refinery) located in Alexandria, Egypt. Scope of the project was the complete development of engineering (base and detail) of the heater, with its air preheating system and all platforms and auxiliary support structures. The supply also included 10 burners, 3 fans, the air pre-heater and all the necessary instrumentation to ensure the equipment operated according to safety regulations.

What were the challenges and what made the project successful?

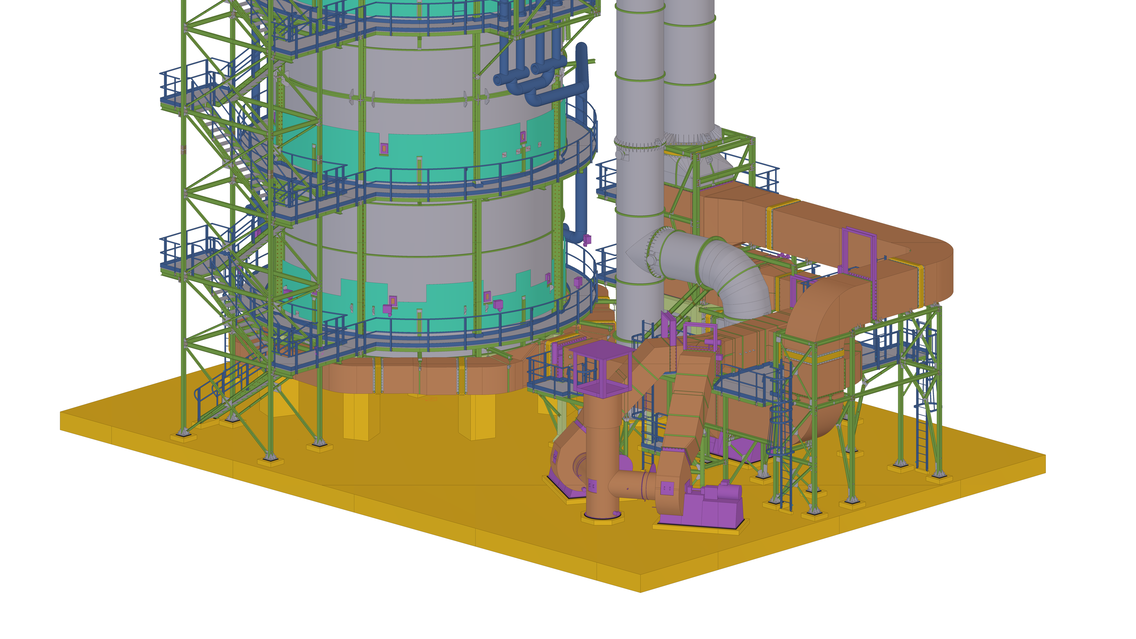

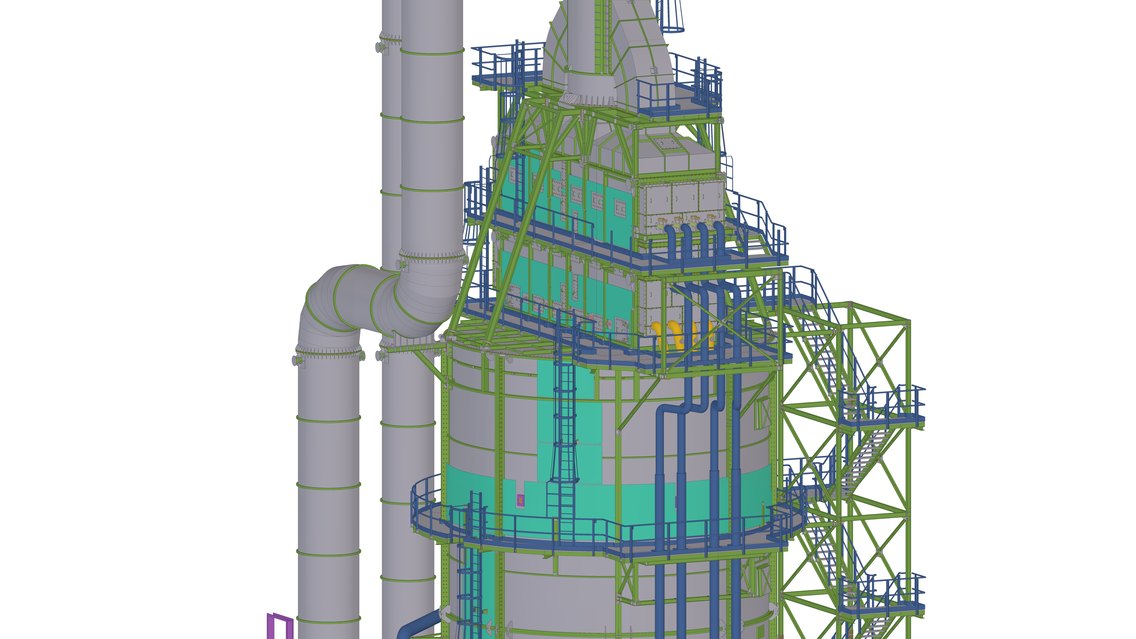

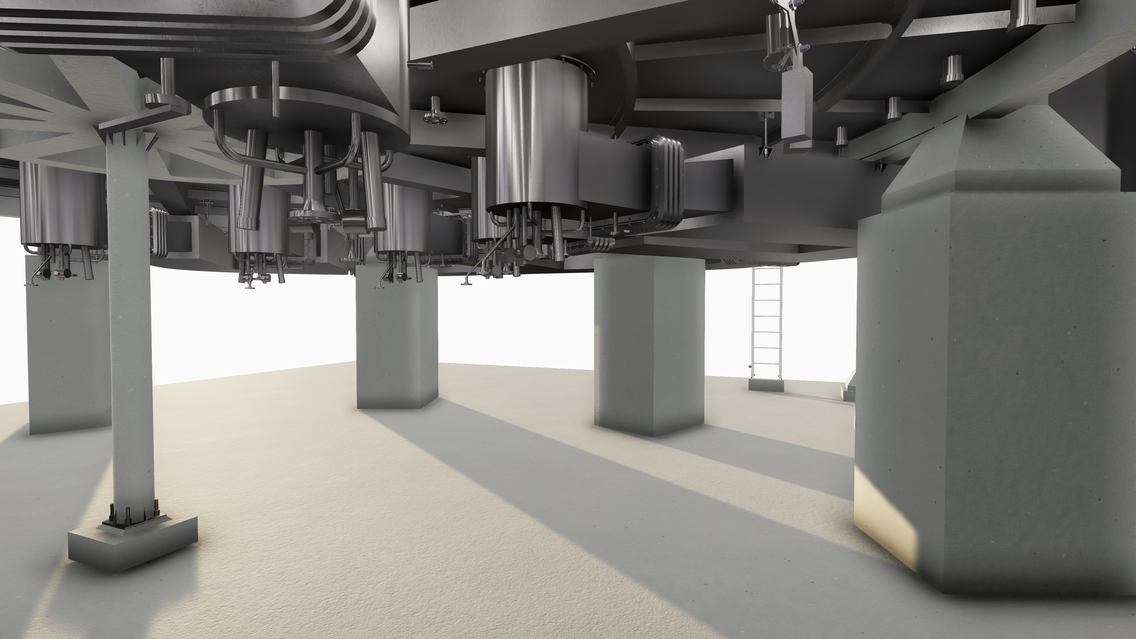

There were two major challenges during this project. The first was the necessity to fit the equipment in a relatively small area in the existing plant, together with several accessibility constraints imposed by project specifications and other requirements imposed by instrumentation. This led to a very compact routing of the ducting system and the necessity to develop the same on different floors. In this activity, the 3D modeling of Tekla Structures has been fundamental in order to correctly understand the routing from the first stage in order to meet all of the requirements, to evaluate pros/cons of all possible alternatives and to verify the correct accessibility.

The second challenge was an important modification in the equipment layout that occurred in an advanced stage of design, which required some additional design activities relevant to both structural members and auxiliary structures. The synchronization between the drawings and the objects of the model supported the design team in reducing any impacts on the project schedule and avoiding possible critical mistakes in the engineering/fabrication.