With a project capex of $US18 billion US dollars, Hong Kong International Airport (HKIA) is Hong Kong's largest ever infrastructure spend and DBM Vircon’s largest ever project in Asia. To meet future air traffic growth and maintain Hong Kong’s competitiveness as an international aviation hub, Airport Authority Hong Kong has embarked upon a major expansion project that will see Hong HKIA become a Three-runway System (3RS). Since its opening at Chek Lap Kok in 1998, HKIA has grown to become one of the busiest airports in the world. In 2018, the airport served 74.7 million passengers, handled 5.1 million tonnes of cargo and accommodated 427,725 air traffic movements. With more than 120 airlines connecting to over 220 destinations worldwide, HKIA is a leading international and regional aviation hub that helps maintain Hong Kong’s status as ‘Asia’s World City’. With the airport edging closer to full capacity, there is an urgent need for the expansion to a 3RS. Once complete, the HKIA will be able to serve an additional 30 million passengers annually.

The three-runway system

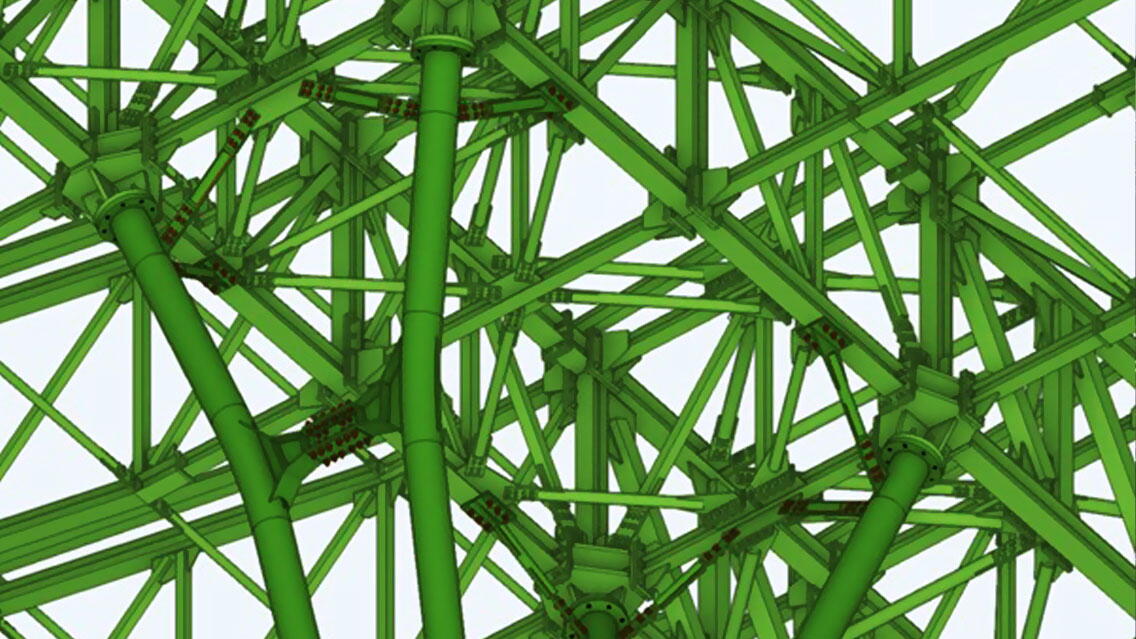

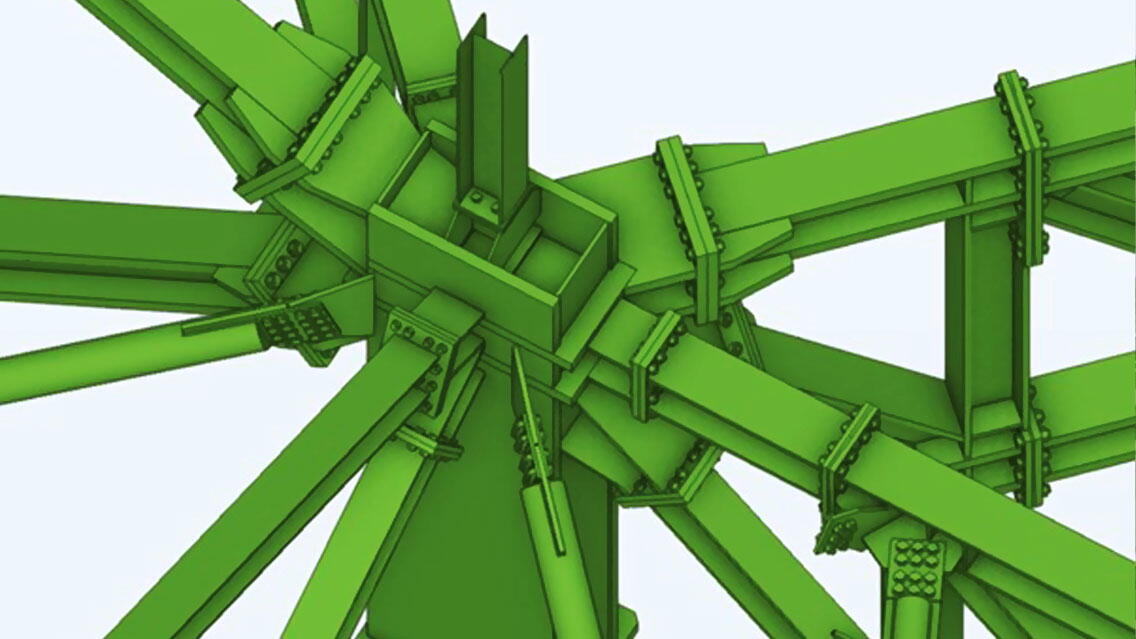

The 3RS project is more than a new runway. Its scale is almost equivalent to building a new airport next to the existing one. The project involves reclamation of approximately 650 hectares of land directly north of the existing airport island. Due to environmental concerns around contaminated soil and increased shortages of materials like marine sand, the land will be built with a process known as deep cement mixing. This involves injecting cement into soft or contaminated soil to stabilise it, removing the need for environmentally damaging dredging to take place. Material is then added to raise the land above sea level. A key element of the project is the Third Runway Passenger Building, which will encompass more than 280,000m2 of floor area, 57 new aircraft parking positions, and an apron. The aircraft concourse is comprised of 23,000 tonnes of steel sections, and approximately 53,000 sticks of steel, which will generate approximately 70,000 to 80,000 connections. To illustrate the sheer size and scale of this aviation mega project, if the concourse structure was to be stood vertical, it would be 785m in height—making it one of the ‘tallest’ buildings in the world. The HKIA project also encompasses:

- Building a 3,800m long new runway and its supporting taxiway systems. The existing north runway will also be reconfigured.

- Building a 2,600m long new Automated People Mover system connecting Terminal 2 with the new passenger building. This new APM system travels at a top speed of 80km per hour and will take 2.5 minutes to travel from Terminal 2 to the new passenger building. It can transport upto 10,800 passengers per hour

- Building a new Baggage Handling System linking Terminal 2 with the new passenger building with a baggage transport speed of 7 to 10m per second.

- Expansion of the existing Terminal 2 to provide arrivals, departures and full-fledged passenger services.

- Construction of other associated airport support infrastructure, road network and transportation facilities. With the land reclamation complete, work on the above ground infrastructure has commenced. It is expected that the new 3RS at the HKIA will be in operation by 2024.

DBM Vircon’s scope of work

DBM Vircon was engaged directly by the owner, the Airport Authority Hong Kong, to provide specialist modelling services for the new 57 aircraft concourse that will service the existing second runway, and new third runway.

DBM Vircon was engaged at an early stage to work collaboratively with the project engineer, moving away from the traditional staged silo mentality that is usually associated with delivering a major infrastructure project. DBM delivered a fully connected design intent Tekla model for tender and LOC purposes, with the successful contractor then utilizing the model to produce erection methodologies and 2D fabrication deliverables. This way, all the steelwork details will be fully resolved, and the design complete at the time of contractor engagement. As such, the Airport Authority Hong Kong will be able to significantly de-risk the project by removing any assumptions or unknowns within the engineers’ traditional 2D design, which traditionally translate into fabricator claims and delays to the project.