Project Data: approx. 5.300m³ precast concrete (about 1,300 individual parts), approximately 10,000 m³ situ concrete

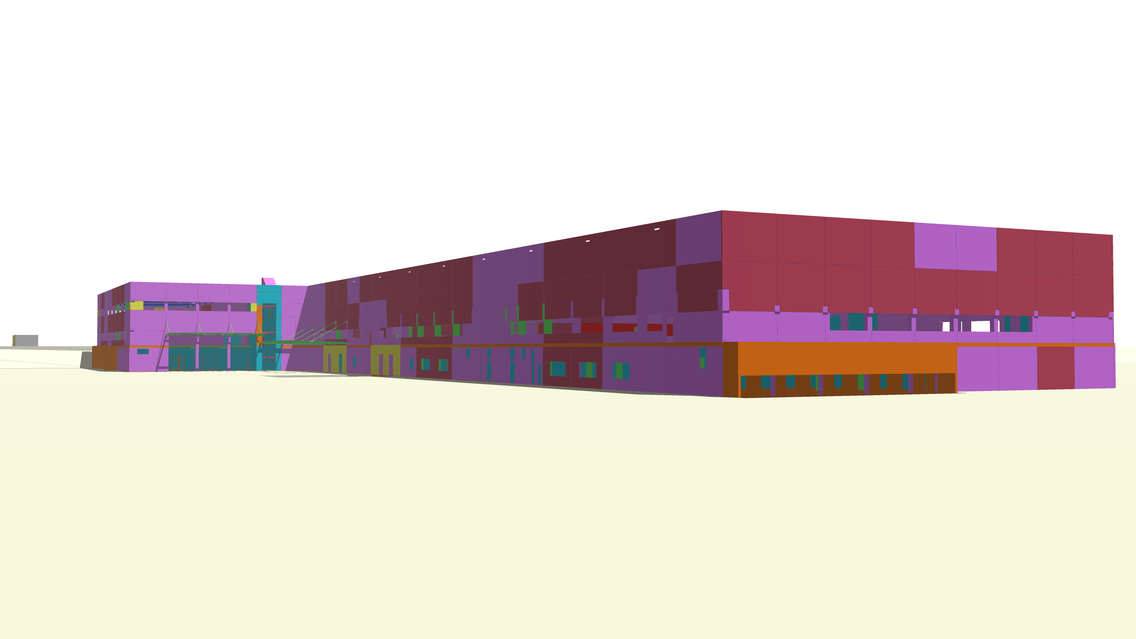

New production building of Getzner Textile Weaving GmbH in Gera, Germany. The engineering company Bauconsult Hermsdorf was responsible for the entire project, the complete structural design, structural calculation, formwork and reinforcement planning, precast planning. One of the core competencies of the engineering company is planning constructive reinforced and precast concrete elements. For precast planning the company relies on advanced planning tools, as also in this project, which was carried out using 3D BIM.

Accurate offer by BIM

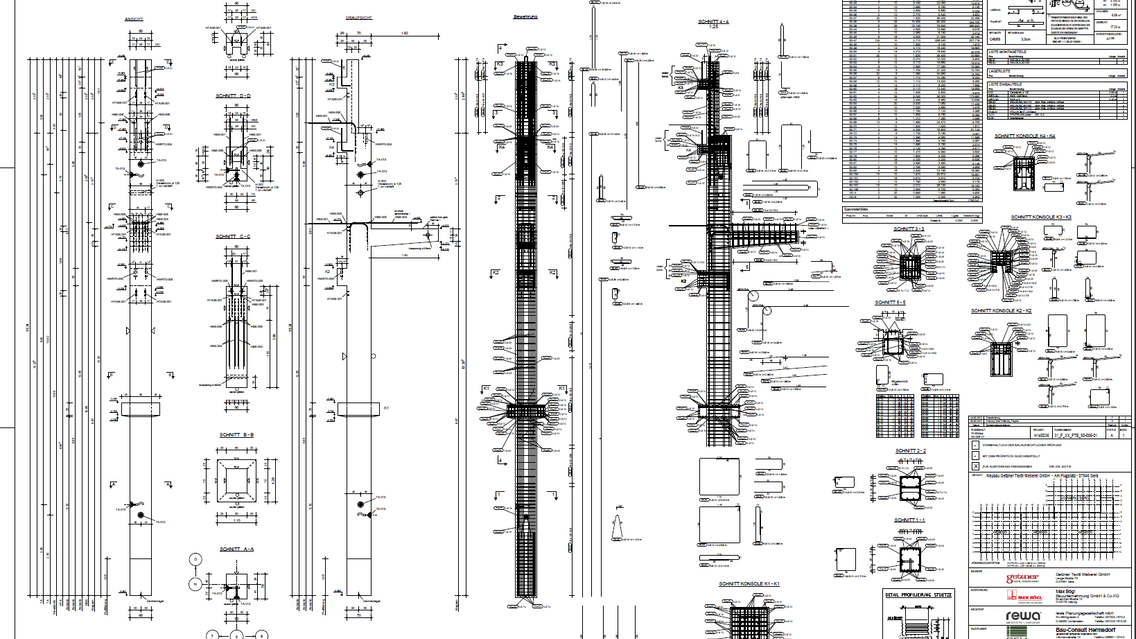

The project comprised initially the construction of three manufacturing halls as well as pre- and post-fabrication areas, logistics facilities and administrative and social rooms. But already during the construction period, the extension to a fourth weaving hall was planned and is currently in the installation phase. The biggest challenge for the project team was the need for a column-free manufacturing hall. The resulting 40m-long I-Binder presented both for static analysis, and detailing anything but an everyday challenge. Tekla Structures was used already for the bidding phase. A costing model was created, which at an early stage enabled an accurate calculation of quantities by an appropriate level of detail and the focus on the use of precast concrete products. Through the use of parametric profiles different design variants could be run through and evaluated in a short time.

Model once – use anywhere

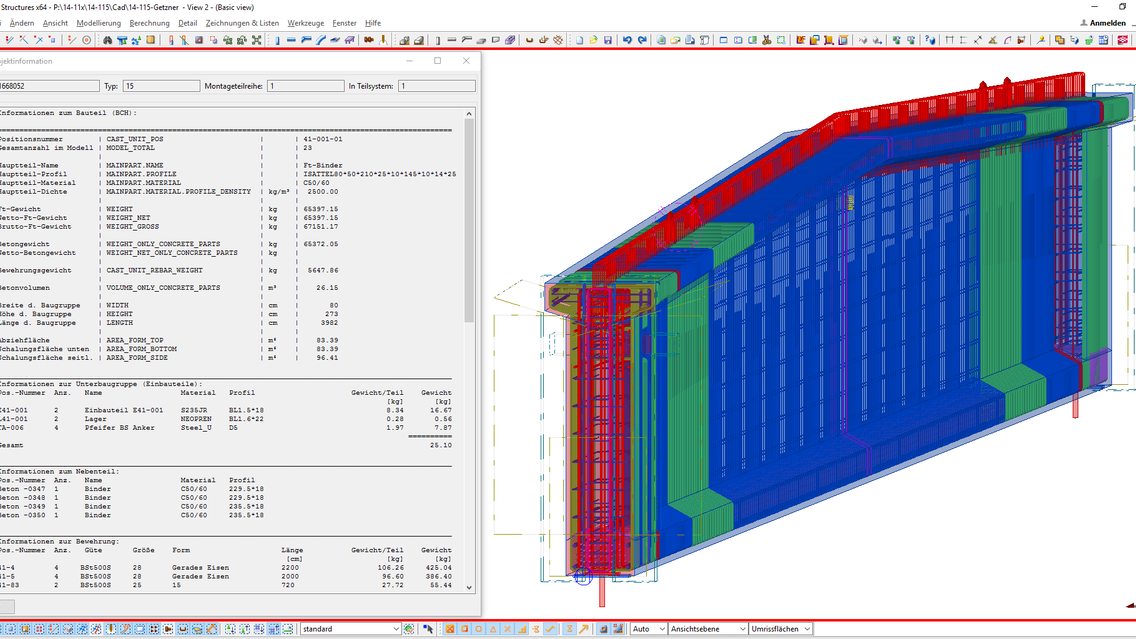

In the implementation phase, the design team applied the BIM-planning philosophy "even modeled - used everywhere" in practice. Some components of the calculation model could be transferred and processed. Tekla-Software´s ways to manage large amounts of data and elements were fully played out, since all precast concrete elements were fully reinforced in the model and were provided with all build-in and assembly parts. The assembly parts Tekla elements came from the company's internal component catalog, making the modeling effort greatly shortened.

In addition to the purely geometric information components (CAST_UNIT) carry further data, such as information on the design process status of each component (modeling, drawing, testing and release). This information was included in the data management of the precast fabricator Max Bögl through a weekly synchronization. The status information provided were used there, among other things for the assembly planning and progress visualization.

Benefits of BIM and Tekla in this project:

- The usage of parametric profiles in Tekla made the bidding very accurate and efficient. Different design variations could be run through and evaluated in a short time.

- In the implementation phase several components from the calculation model could be reused, based on the BIM-philosophy “model once – reuse anywhere”.

- Tekla Structures capacity in managing large amounts of data and big models. Especially large projects also benefit through a secure identification of identical parts.

- Changes can be delivered rapidly through the associativity of the model and plan.