The following project was part of the revitalization of the Hungexpo

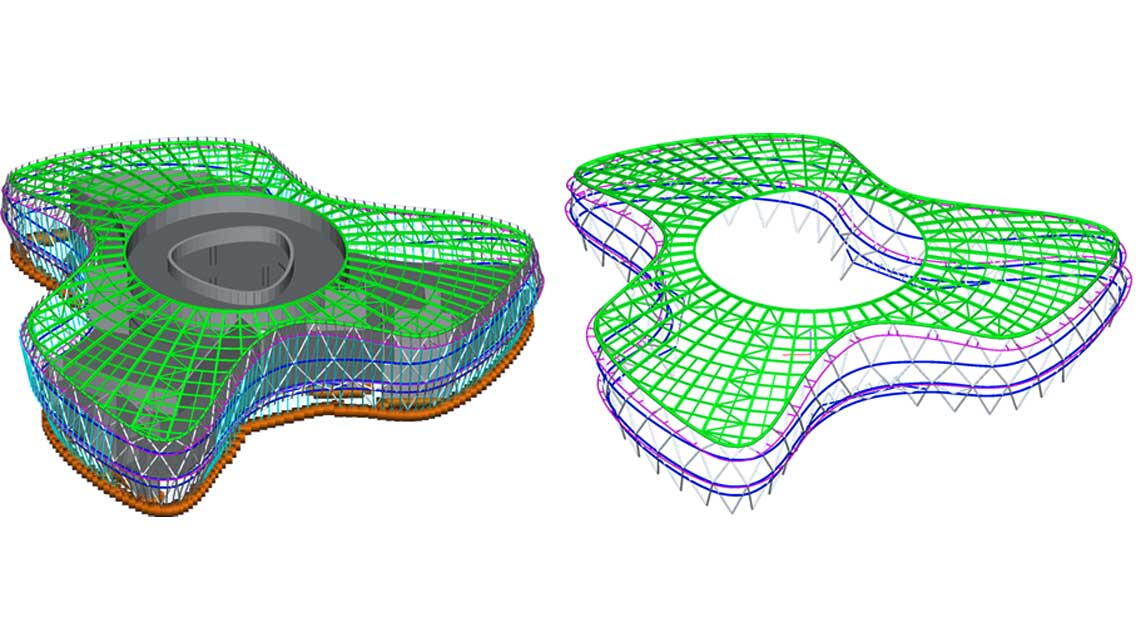

Budapest Fair. The F1 Arrival Hall is a propeller-shaped building with complex structural geometry. The main structure is supported by a concrete core, and a steel exoskeleton frame supports the building’s entire facade and roof.

The facade structure is built from 4 m edge length triangles, made of circular hollow sections. The roof structure follows a sphere surface, and it is built with radial and circumferential steel elements with diagonal bracing. The perimeter beam between the roof and the facade is made of a segmented-curved CHS section.

The design task of BIM GROUP LTD was the detailed design of the steel structure, including fabrication transportation and construction optimization, detail, erection design, 3D modeling, and workshop documentation generating.

The design workflow was based on Rhino, Grasshopper, ConSteel, and Tekla Structures live links, allowing the designers detailed investigations into the geometry. In addition, the wireframe of the steel structure was parameterized and optimized in Grasshopper.

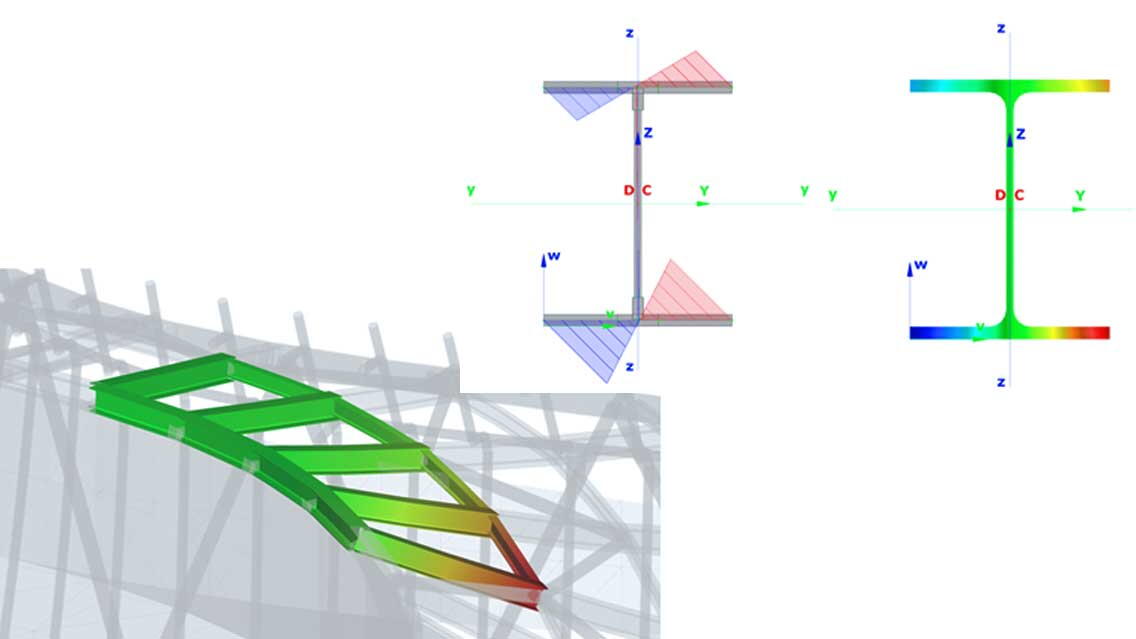

The primary steel structure was calculated with Consteel®, which is a

FEM software focused on steel structures. Consteel was linked directly to Grasshopper via the Pangolin real-time plugin. Joint calculations have been performed in IDEA StatiCa software and linked with Consteel and Tekla Structures.

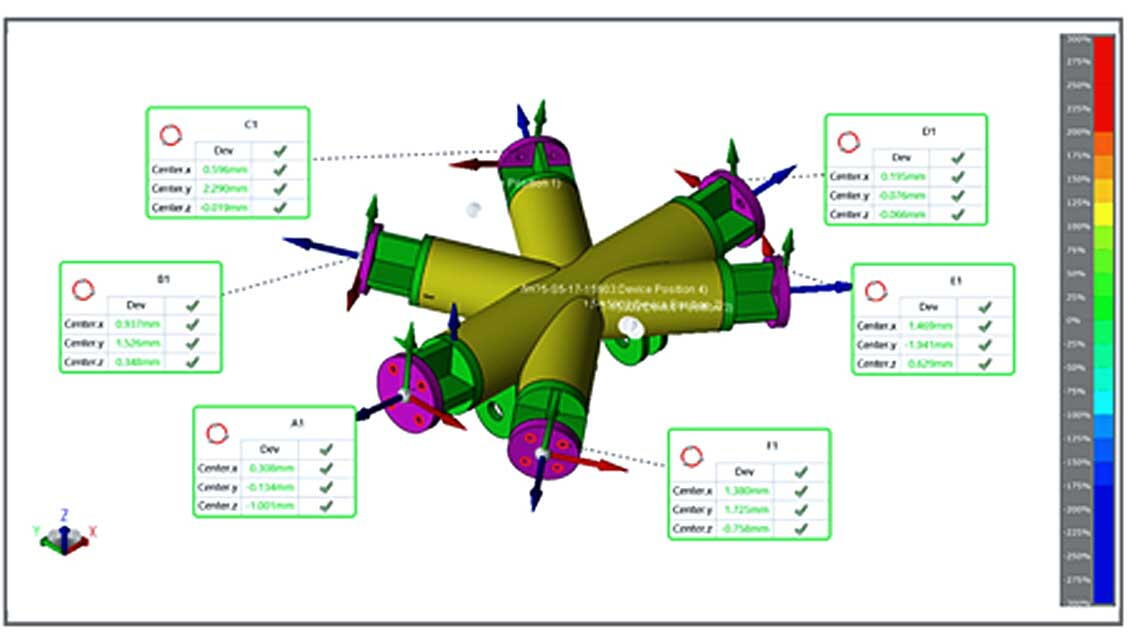

Tekla 2019 was used for steel shop detailing. Tekla was linked to Grasshopper via the Tekla Live Link plugin. In this case, a Grasshopper script generated all the necessary fabrication attributes into Tekla. This method allowed deep and iterative investigations to achieve fabrication, cost efficiency, and the best geometric accuracy with reasonable extra time and design costs.

After the last Tekla model generation, 2D drawings and necessary fabrication documentation were prepared inside Tekla. During the construction period, the site measurements of the steel structure were brought back into Tekla Structures by Grasshopper script for pre-evaluating each unique joint to design the fitting plates.

Key facts

Steel design team:

• 1 full time lead structural engineer

• 2 part-time graduate engineers

• 1 full-time modeler

Duration: 9 months

Area: 2700m2

Steel Weight: 750 tons of steel

Other details: 2000 pcs of joints on the facade, 800 pcs wall purlins

Project Details

Investor: Hungexpo Plc.

Architect: Finta és Társai Építész Stúdió

Ltd.

Structural Designer: Hydrastat Ltd.

Steel Detail Designer: bim.GROUP Ltd.

General Contractor: KÉSZ ÉPítő Plc.

Steel Manufacturer: KÉSZ Ipari Gyártó Ltd.

Steel Erector: KÉSZ Metaltech Ltd.