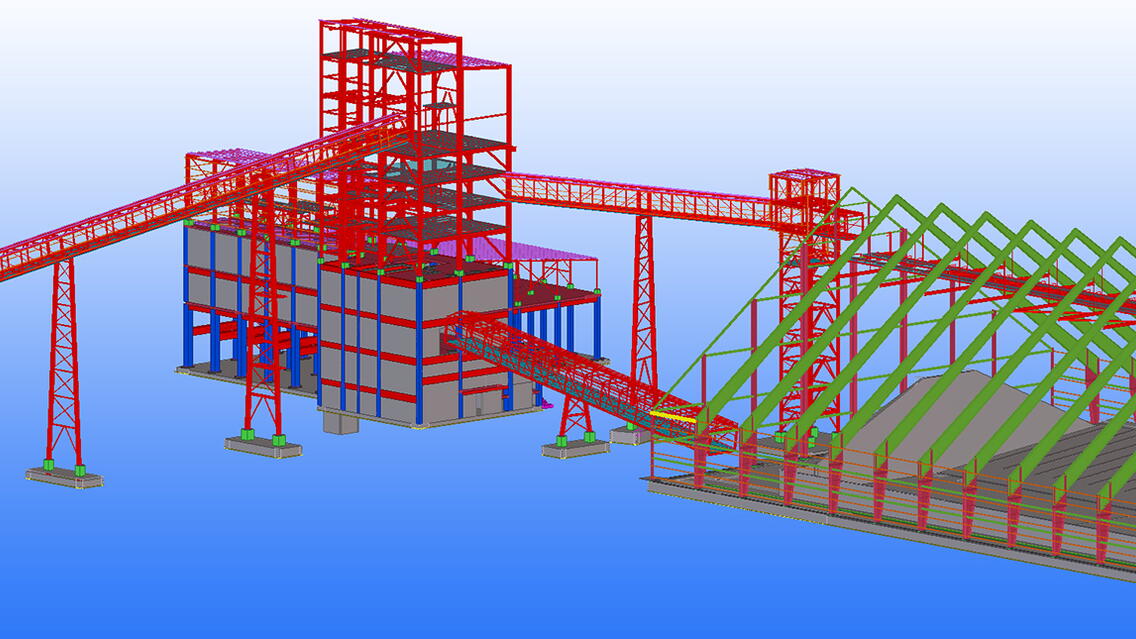

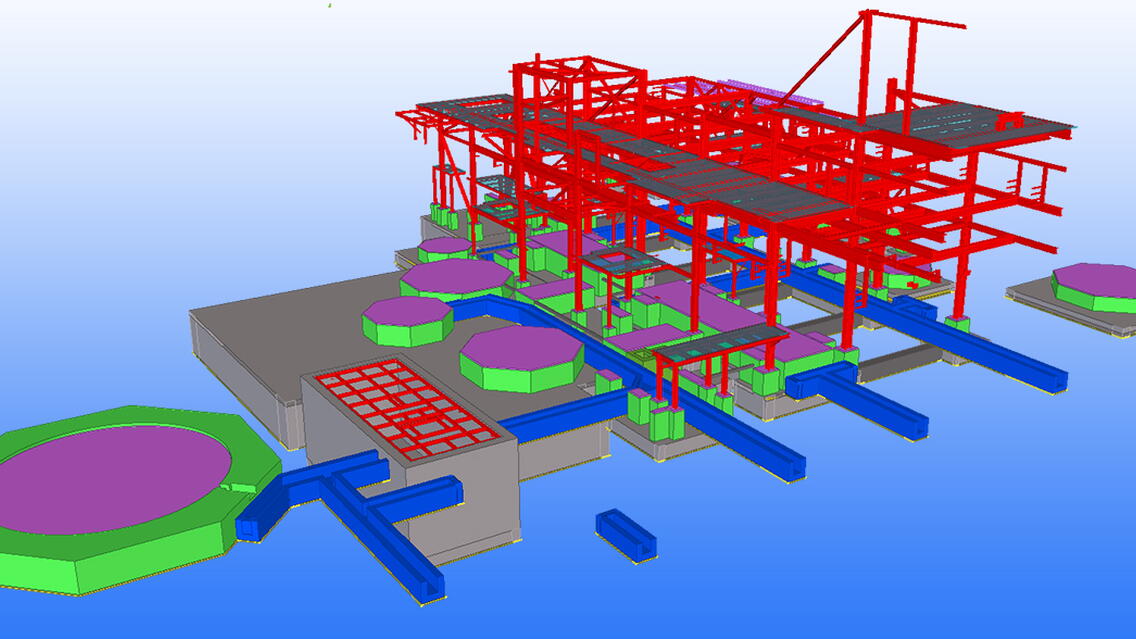

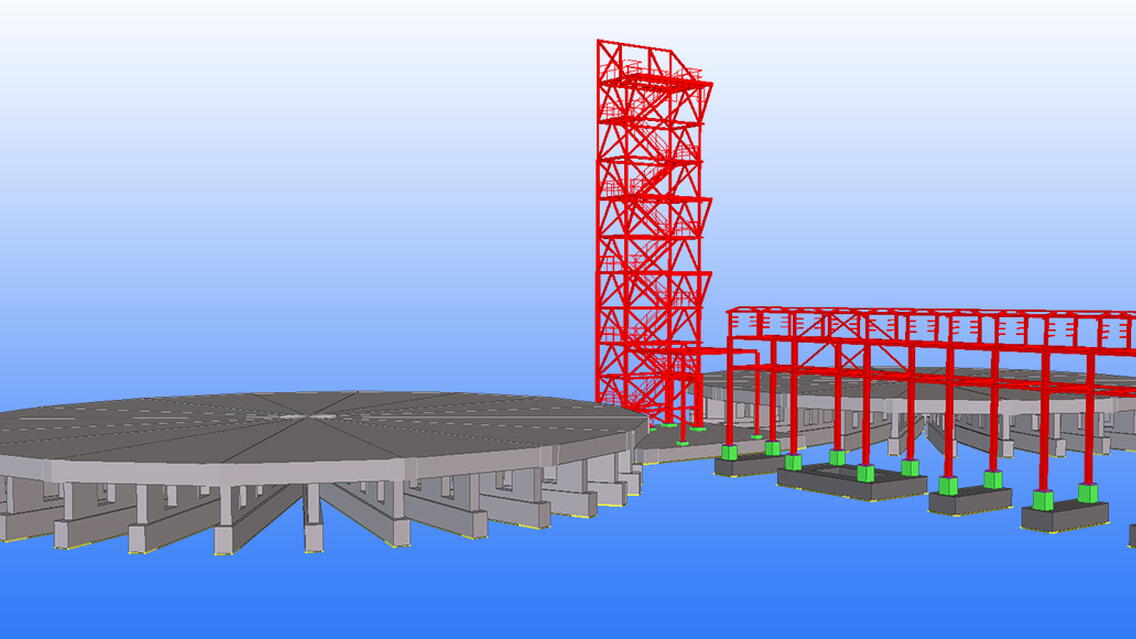

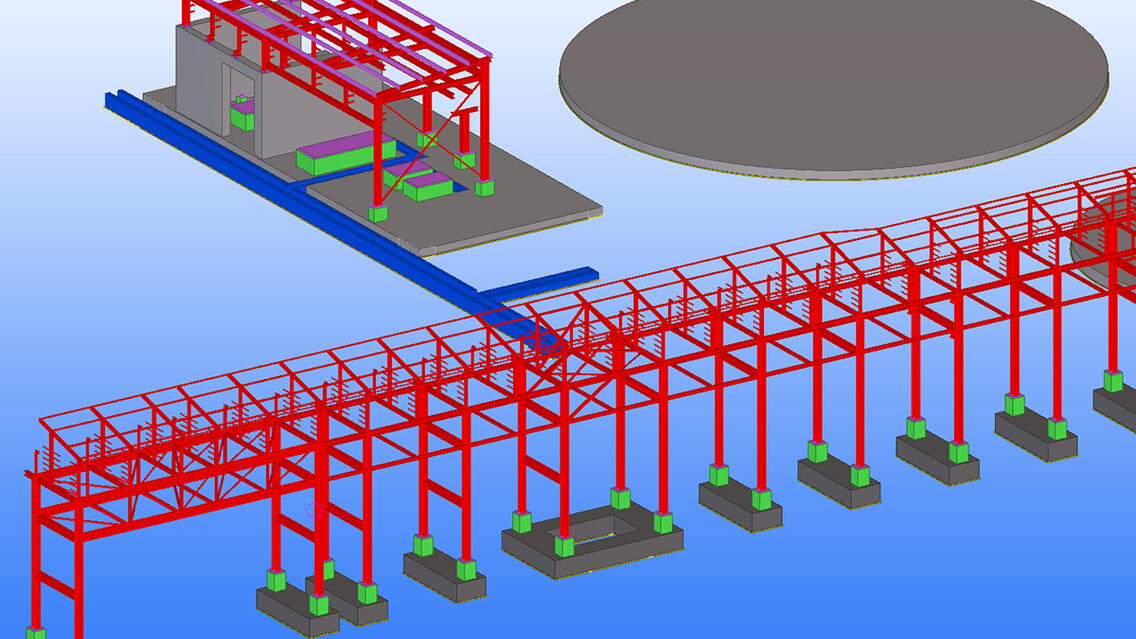

The goal of the project conducted by ThyssenKrupp Industrial Solutions was the generation of quantity takeoffs in combination with project management software RIB iTwo for the quote documentation of a chemical plant complex in Southeast Asia. The project encompasses 17,500 tons of steel, 60,000 m³ concrete and 100,000 m² ceiling and wall paneling. By using Tekla BIM Software to model and coordinate the project, ThyssenKrupp was able to eliminate uncertainties and significantly lower the project bid, making the company optimistic they will be able to secure the contract and move on to the next project phases, then utilizing the Tekla model for detailed planning and design.

The model included various custom components, for example to reference service items in iTwo. The team utilized SDNF and DGN data for steel and concrete construction respectively from the PDMS reference project and positioned these on the floor plan.

The building components were positioned based on 2D-drawings showing the plant layout, which were imported via DWG format. Concrete components were in most cases remodeled in Tekla Structures based on their contour points. Steel components were modified based on the floor plan. For example, pipe bridges which had the same width but different lengths in PDMS were enlarged by copying identical sections of the bridge in longitudinal direction. The Tekla model can now be utilized and further detailed in the basic engineering project phase before it is fully detailed and used to generate drawings for formwork, rebar as well as steel fabrication.

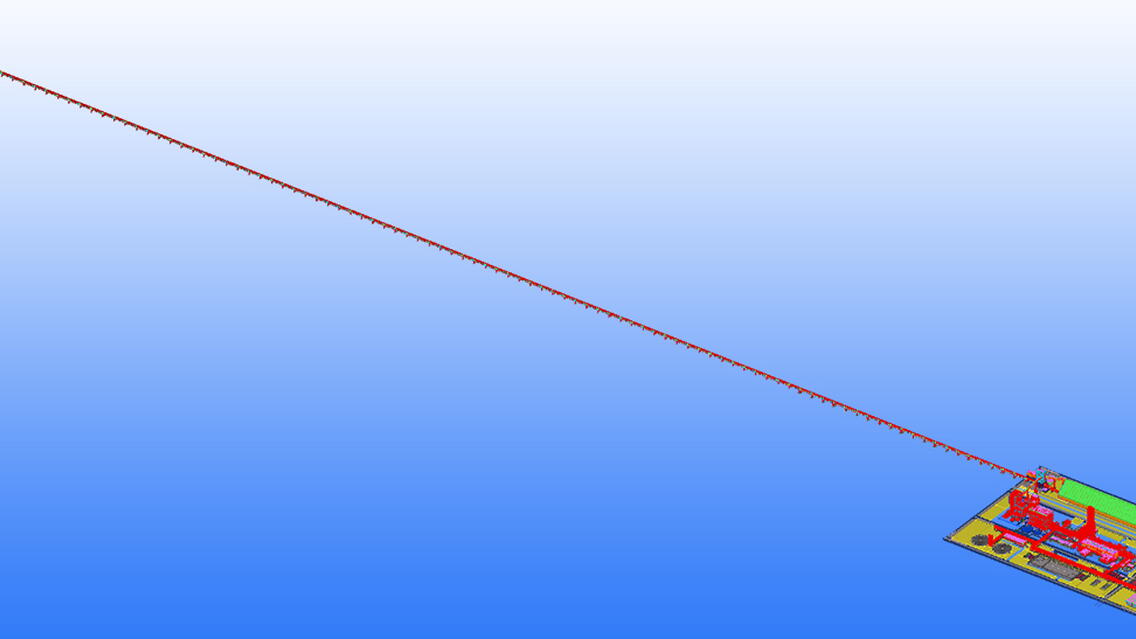

One of the largest challenges was the pure size of the project, spanning 440 by 600 meters as well as a three kilometer long offshore conveyor and consequently a huge number of building components and structures. The team also needed to ensure the smooth collaboration between AVEVA PDMS, Tekla Structures, MS EXCEL und RIB iTwo.