Bridge over the Stuttgart motorway

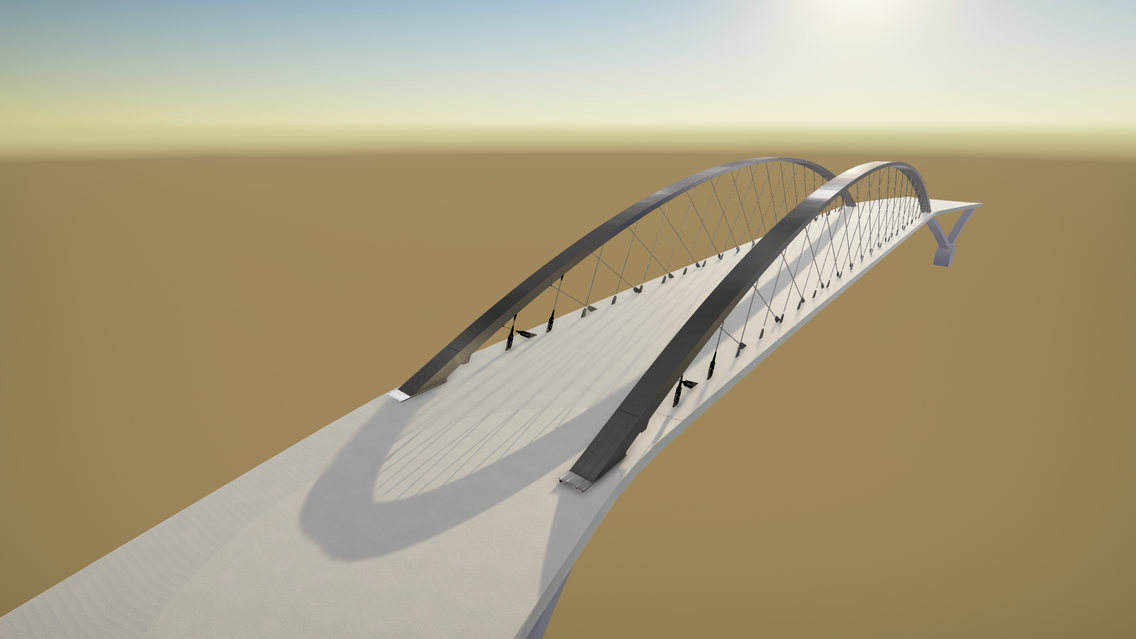

The bridge is designed to cross the extended U6 city line east of Stuttgart over the motorway BAB A8.

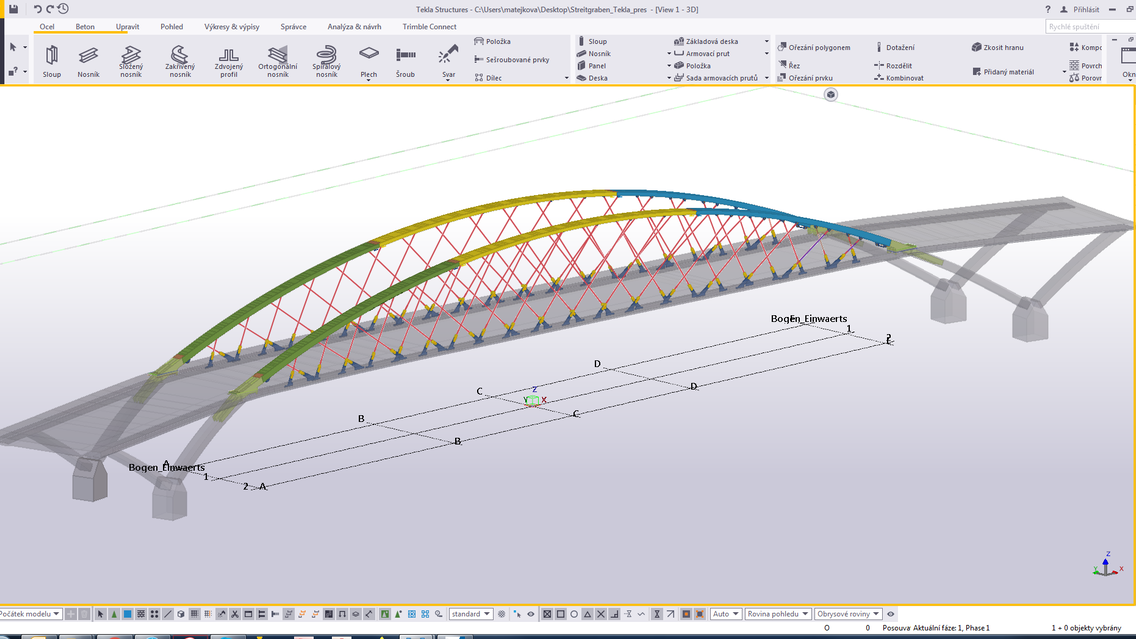

Construction

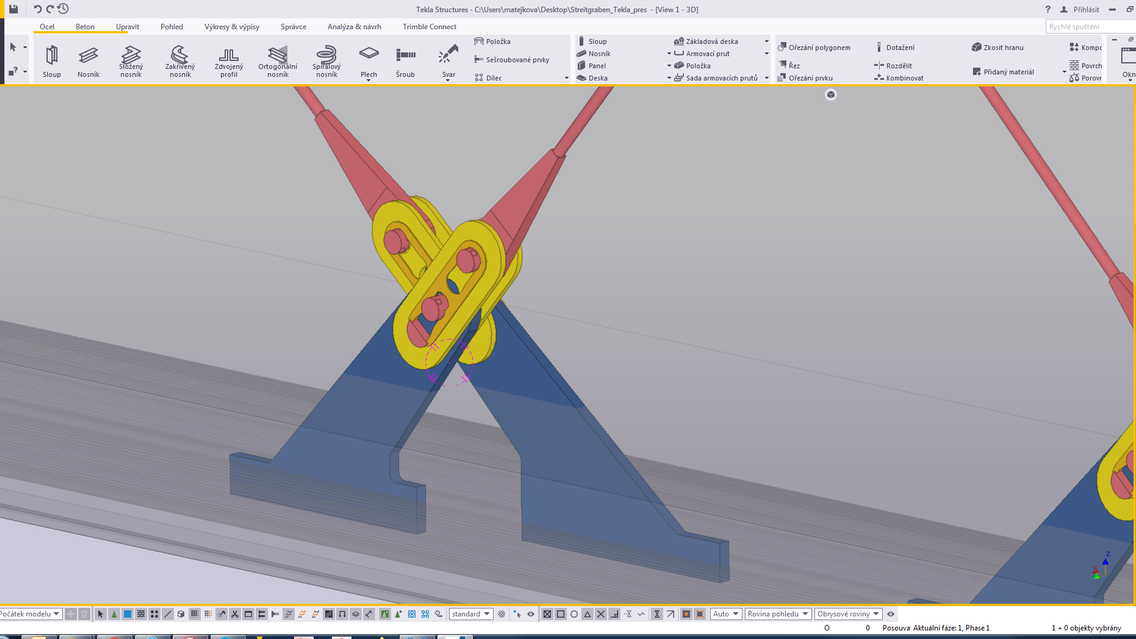

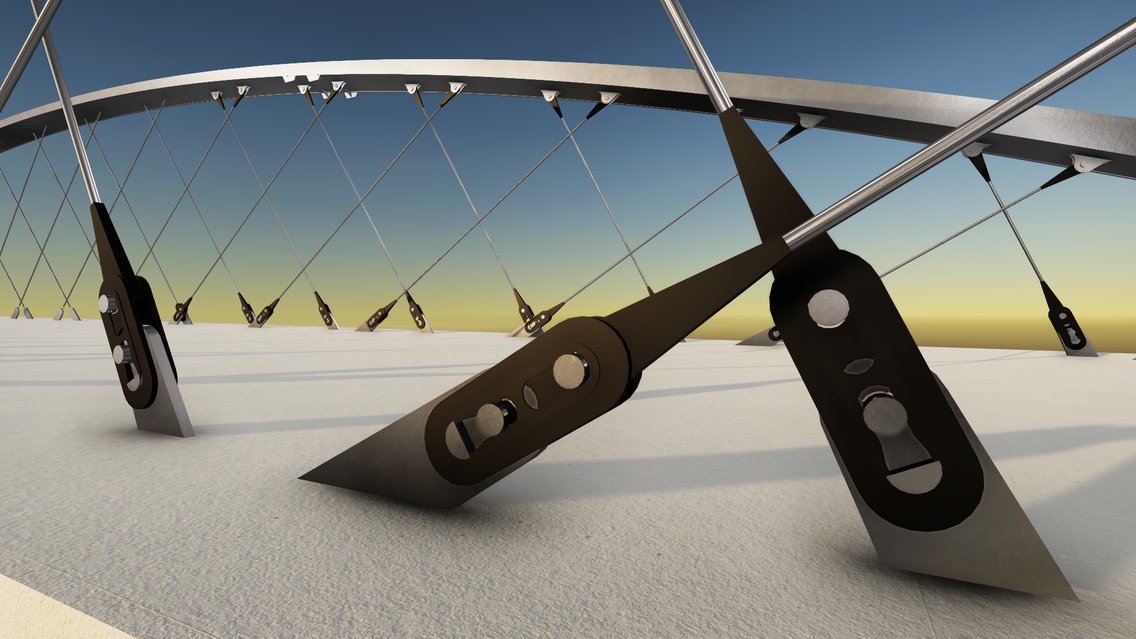

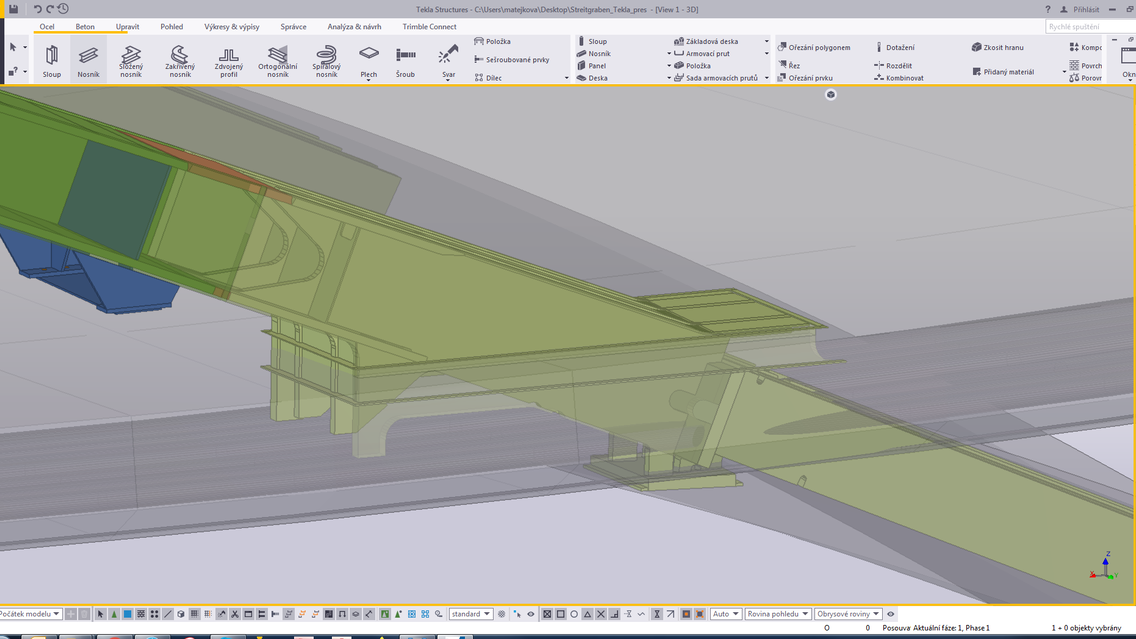

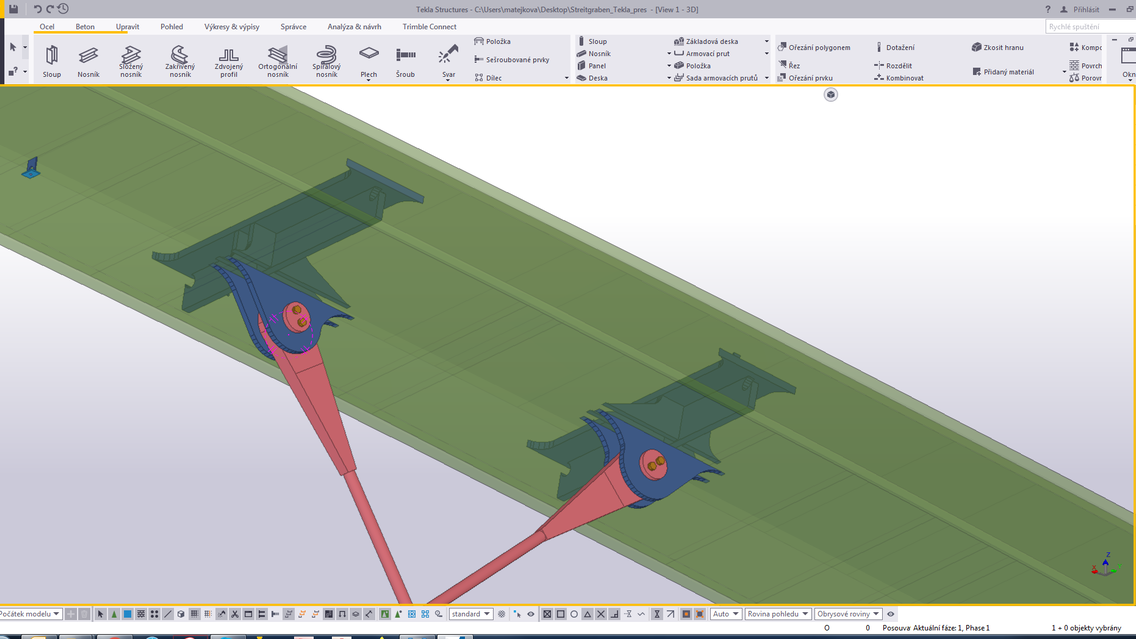

Construction of the bridge is designed as a continuous beam with three fields. The total length of the bridge is 127 meters and the width is 11.7 meters. The height of the arch is 8.16 meters. The main part of the bridge with a span of 80 meters consists of a steel arch and massive prestressed concrete deck. These two elements are connected by a network of rod prestressed elements made of carbon fibers. The rods are connected to the arch and bridge deck by pins. Joint plates with shear studs and openings for prestressing cables are concreted into the bridge deck. A prestressing system of rods is implemented in the connection of rods into the bridge deck.

The steel arch is designed with variable cross-sections. At the top, the cross-section of the arch has a width of 1360 mm and a height of 300 mm. The foot of the arch, has a width of 1000 mm and a height of 600 mm. Due to the side walls of the arch are formed by a wrapped surface, the arch is connected to the bridge deck by a foot segment which follows the arch, and by four plates running into the bridge deck. The foot segment follows the layout curvature of the bridge deck. Due to that the concreted plates are spatially rotated relative to the arch.

The entire bridge was pre-assembled, including the concrete deck, and then transported to its final position.

The weight of the steel structure was 250 tons.

The model in Tekla Structures was processed as per the customer’s order, as a feasibility study using a 3D BIM solution for the workshop documentation of the bridge. The BIM solution had to include complete management of all elements, NC data for automated production, including all workshop and assembly welds.

The model was completely created in Tekla Structures, including weld elements and preparations for the welds in the model. The model had to enable the inspection and management of all welds by the customer – from automated production of the NC data to the reports of weld volumes for the control of production and assembly. With regards to the wrapped surfaces of some elements, unfolded shapes of these plates were verified by specialized software Rhino.

Allcons Industry s.r.o. supplied complete workshop drawing documentation for the bridge. This was supplied in a different software with regard to the production and customer requirements.