Project description

A new power plant unit has been under construction in Turów since 2013. This new unit uses the latest technology solutions and will replace 3 old units. Replacement will bring about a significant reduction of pollution and CO2. The owner of the urów Power Plant is the PGE company. Main contractor is a consortium of 2 companies: Mitsubishi Hitachi and BxTR (Budimex and Technicas Reunidas), which has hired Energoprojekt Katowice (EPK) to deliver and coordinate the workshop and execution design for all branches.

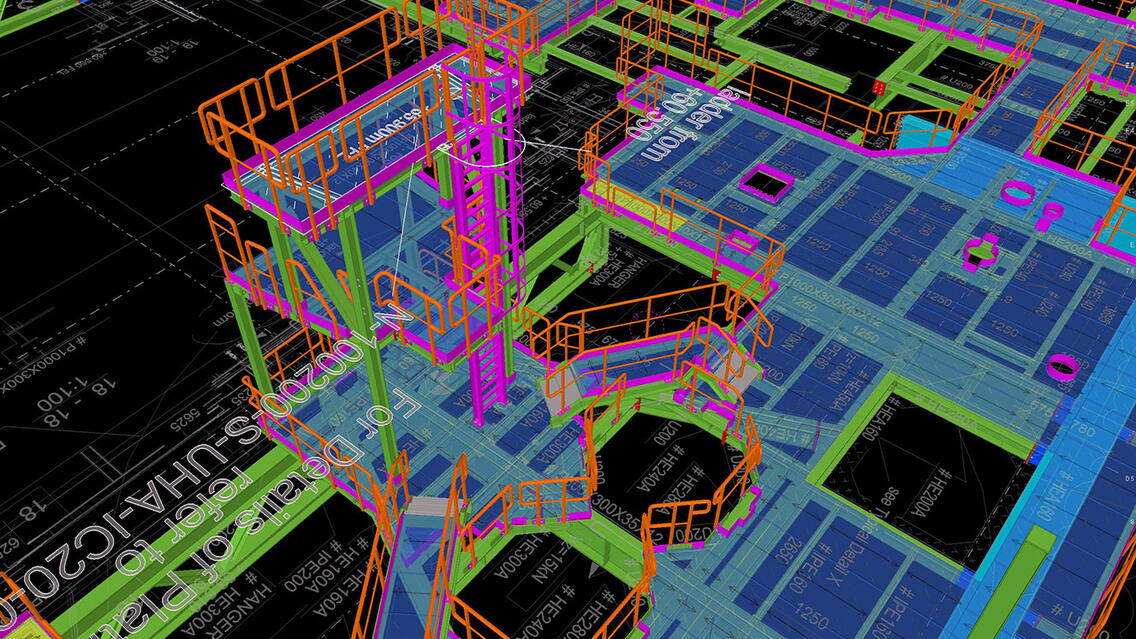

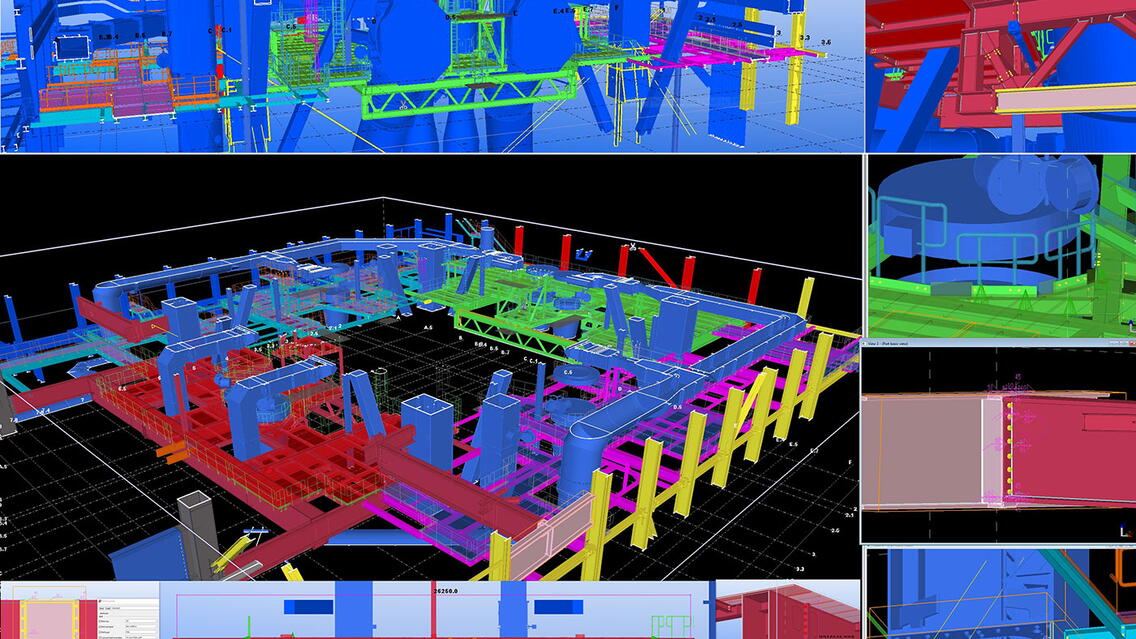

In2016, Jakosta received a contract from EPK to prepare the workshop design of the boiler house. This building along with bunker house and air preheater building is called boiler island, which is the heart of the power plant.

Project in numbers:

1) Tonnage: over 13,500 tons without ducts (scope of Jakosta: 8,000 tons).

2) Object's dimensions: 60mx86m, 116m high.

3) Max tonnage of single assembly element: 100 tons.

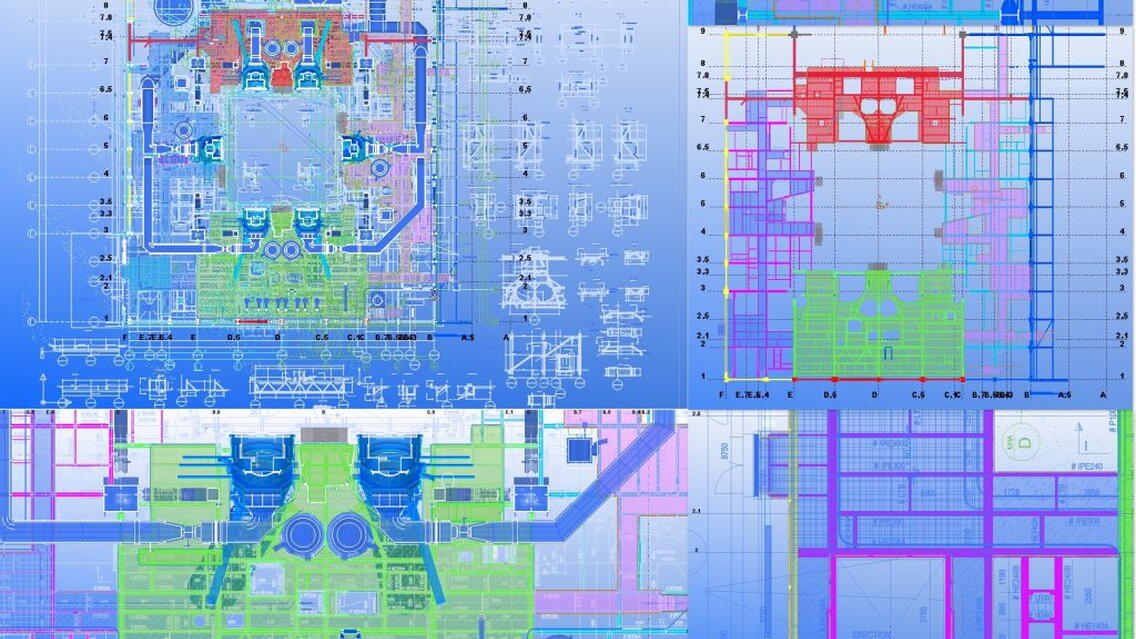

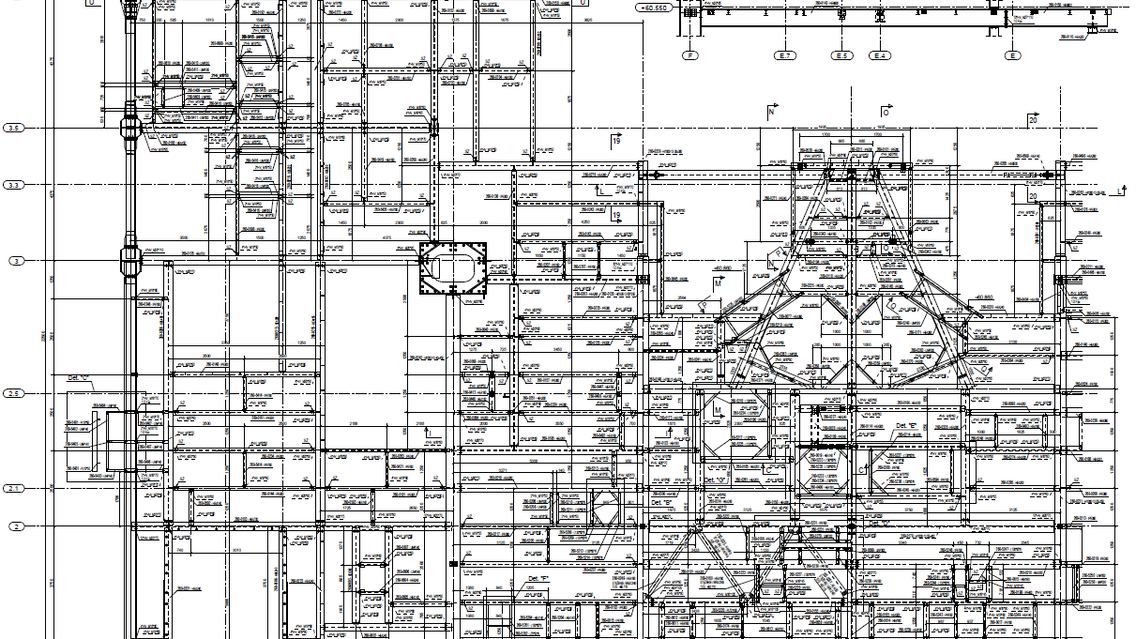

4) Over 6,000 A0 shop and erection drawings.

5) Over 20 grades of steel has been used.

Currently (May 2018), the erection of the steel structure is almost finished. The construction site has reported a very small amount of minor mistakes, which confirm the success of the project.

Special challenges

Main challenges:

1) Size of project, plethora of data to consider and coordinate including over 1,000 reference models of technology, systems etc., updated often

2) Heavy industrial structure with significant internal forces in every direction (values in mega-newtons [MN])

3) High level of detailing:

- individual static calculation for every joint

- detailed information regarding element's milling, ultrasound examination, preparation for pre-loading at single part level

- various steel grades used depending on type of structure, element's static utilization type and profile

4) Extremely complex numbering system which considers:

- static pos. number

- erection "Cubus" (location in structure) number

- type of structure

- billing position (!)

What made the project successful

EPK has been providing services in the power industry for over 60 years. Jakosta has successfully delivered many workshop designs of heavy industrial steel structures in the last 15 years.

In other words, experience of companies involved in this investment was a key factor to the overall success.

Utilization of Tekla Structures was vital to ensure effective coordination and data exchange.

A multi-stage verification process, designation of an independent checking team along with customized components and utilization of Open API on a large scale were very important for providing the finest quality design within given short due dates.