The project is the fourth stage of the development of the Royal Canal Park district in Dublin. The purpose of the design is to raise a multi-use housing estate, which contains five blocks with a total number of 435 apartments. The estate will provide about 4200 m2 of retail space and a recreational area. Residents will also be provided with a pharmacy, health clinic, gym, public squares, office spaces, and 255 parking spots.

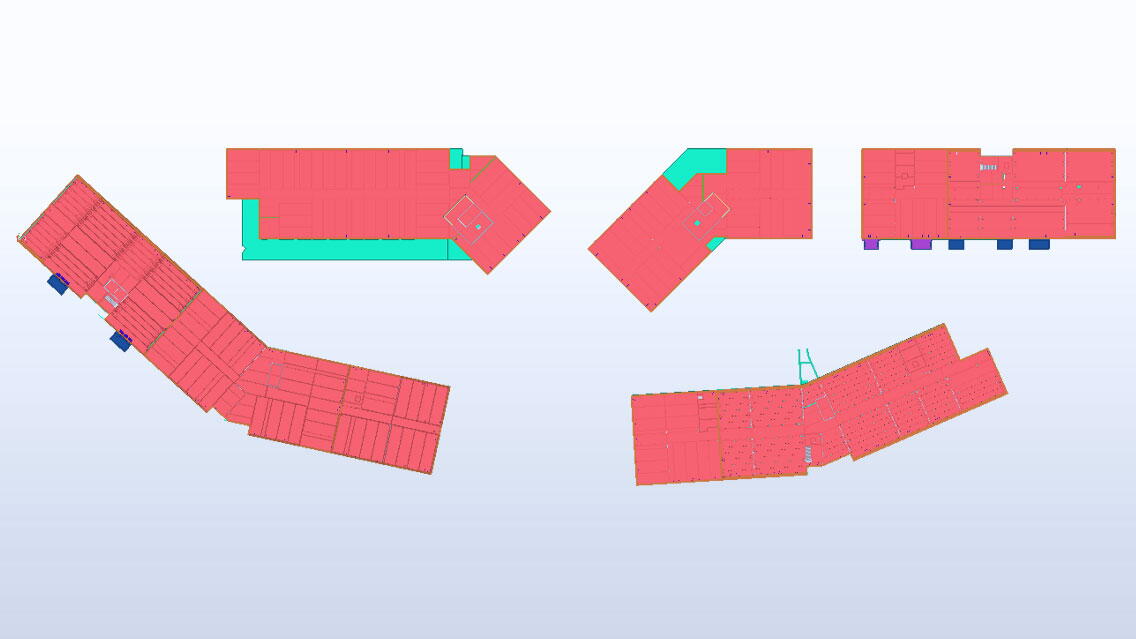

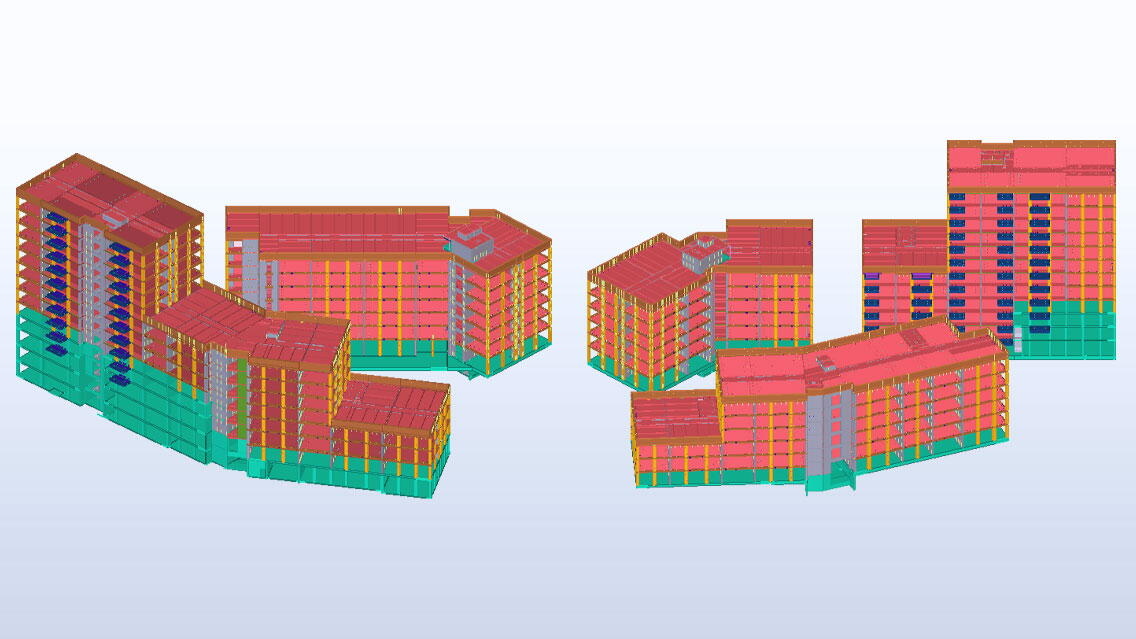

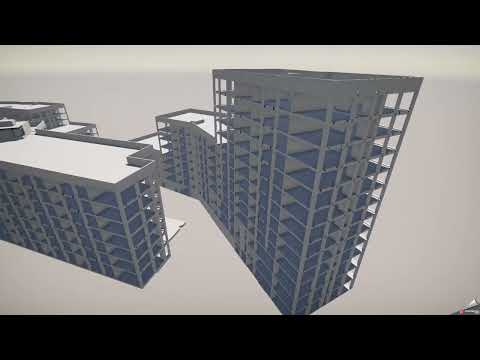

Our team was responsible for the preparation of detailed design and the workshop project for the five mentioned apartment blocks. The highest blocks – block A and block D – have twelve floors, the lowest ones – block E and block C have six floors, whilst block B consists of seven floors. All the blocks are specified with a unique plan structure and differ in their arrangement of the stories. Blocks A, E, and D have been arranged with green terraces on intermediate levels. The roofs of blocks C and B were used for terraces.

In each of the blocks, a combination of reinforced concrete and precast construction was used. The ground floors of all the buildings were designed of in-situ concrete, and all the following levels were precast construction. Only blocks D and block A were exceptional, where there is a reinforced, concrete structure designed up to the third level due to the location of the gym, office spaces, and health clinic. The precast structure is comprised of a column-beam frame in the line of the facades and solid interior panels. Cantilever precast balconies were designed in block A and block D. The balconies were joined to the building structure using a special connection system to minimalize the thermal bridge and to meet fire resistance specifications.

Peripheral beams on the slab level support the facade and stand as a support element for cantilever steel balconies. The special connectors delivered by the balcony’s manufacturer were cast in the precast elements to fulfill this connection. Due to very specific accuracy requirements and assembly tolerance, the connectors were quite challenging in the production aspect and for the construction site team.

Due to the size and complexity of the project, the entire design was run with BIM technology. The interprofessional cooperation was carried out with the use of Asite platform and CDE software such as Trimble Connect and BIMCollab. It was crucial to resolve any errors in the 3D model by ongoing coordination to prevent any collisions and problems which could have been met on the construction site.

The level of design complexity was also raised in accordance with the fact that stair cores were not covered with any finishing material. Therefore, the investor requested a high-quality surface finish of any visible concrete element, and that any connector would not be visible.

The entire project was a challenge for every professional that took part in the design due to its size and the number of elements involved. Our team not only had to work with a difficult working model and drawings but also provided effective coordination work. The project was very demanding not only for our design office but also for the production company and assembly team. For this project, we have prepared a total of:

- 1910 precast walls

- 932 precast columns

- 930 precast beams

- 3160 slabs, consisting of hollow cores, prestressed slabs, and reinforced slabs

- 190 precast stair flights