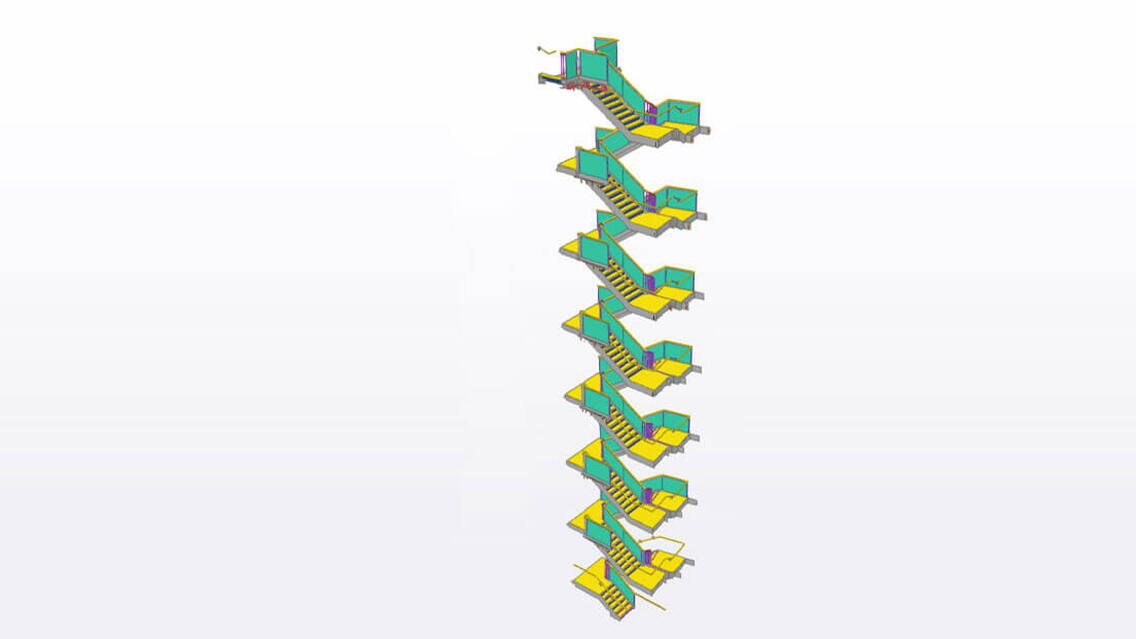

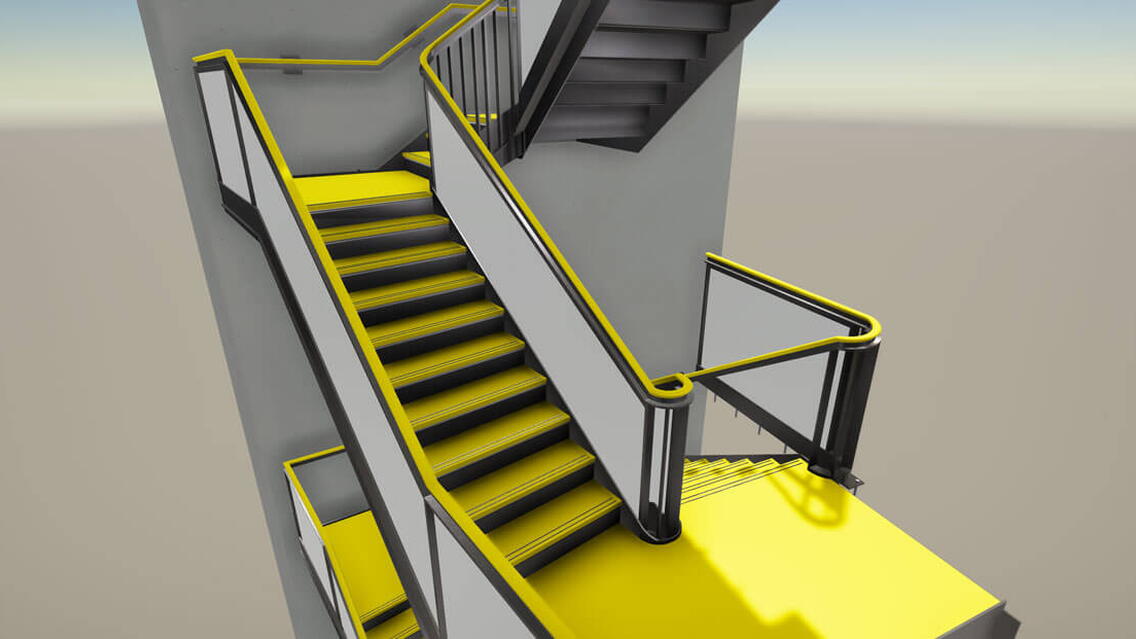

Feature Stair is situated inside new premium retail letting space on Oxford Street

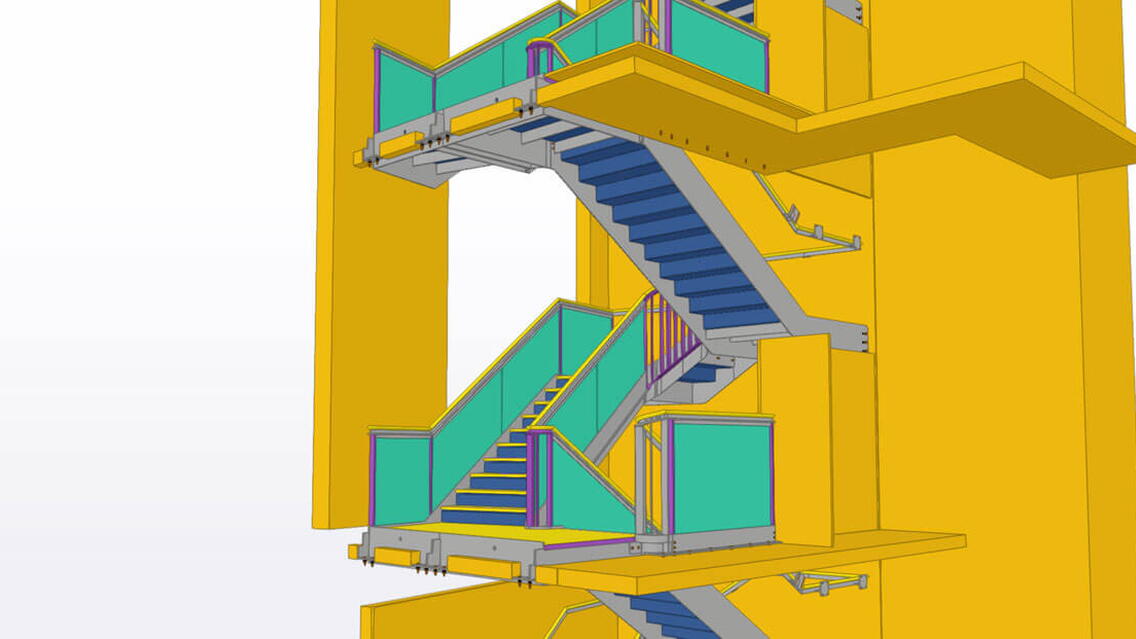

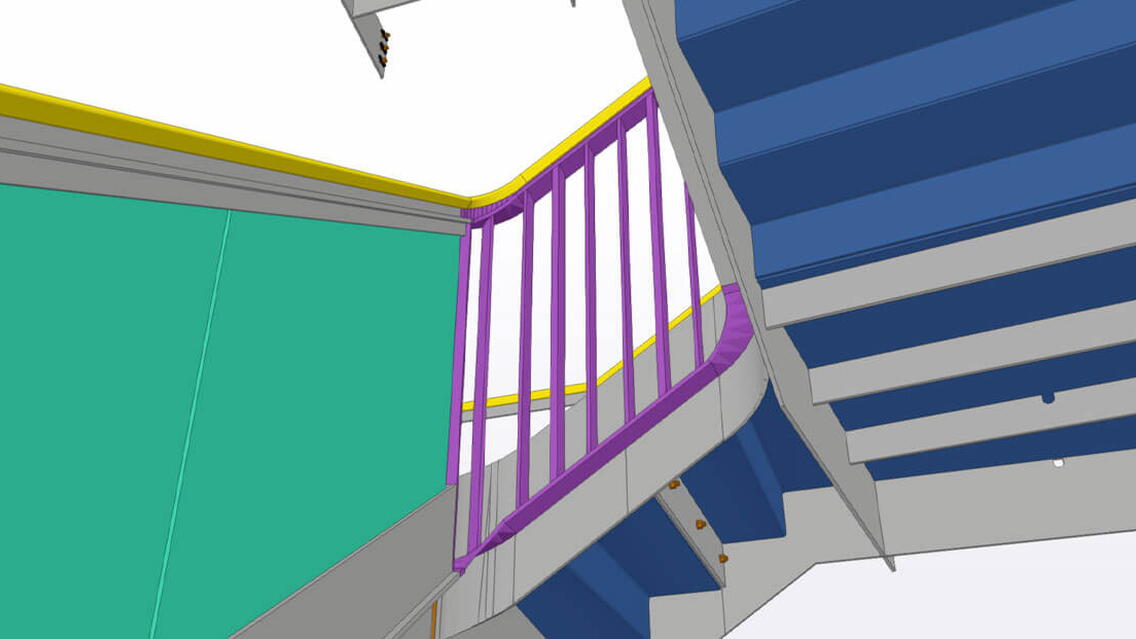

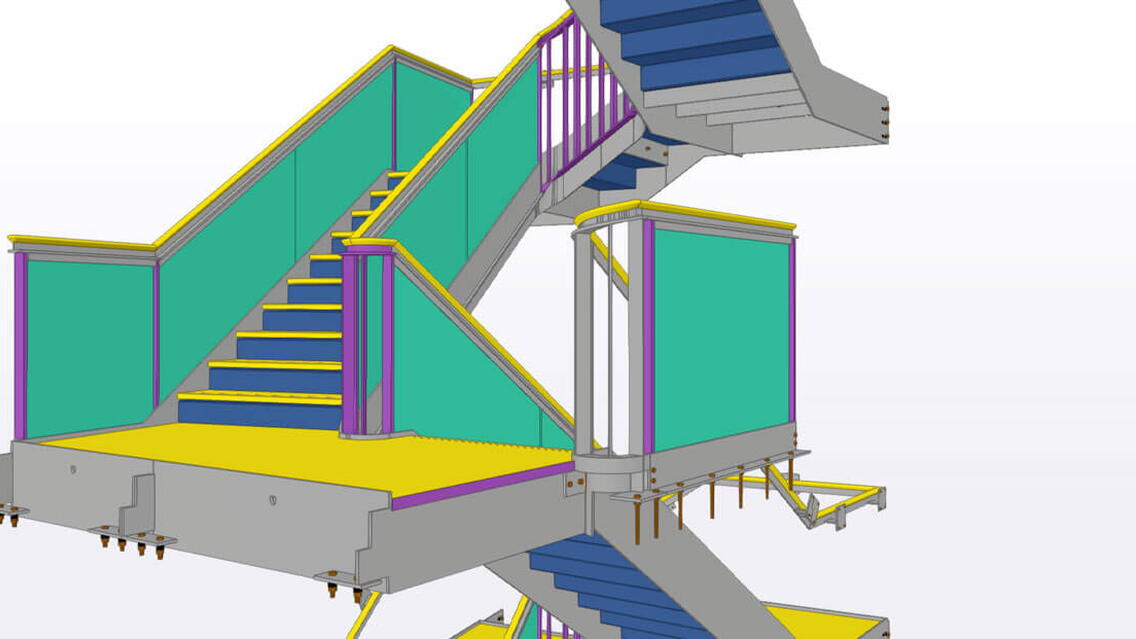

It compromises of a triangular shaped steel staircase and landings, two types of balustrade were also required to the staircase consisting of glass infill to the stair flights and steel infill bar to the stairwells. The handrail is from a European Oak profile along with the stair treads and landing floors.

Project for us ran from early 2019 to March 2020. TDS were enlisted by a regular fabricator we work for to carry out all drawing work. Due to the design of these items there was an increased input between the engineer / architect and main contractor with our specialist design team.

What were the challenges and what made the project successful?

The main obstacles we had to overcome were due largely in part to the complex triangular geometry of the staircase in such a tightly confined space. In addition to this the architectural intent for the well and landing returns of the flights were to be curved making them helical in nature. Due to the complexity of this area we were able to utilise Tekla Structures' triangular plate function to map out the geometry of the helical stair stingers and balustrade which is where Tekla exceeded and we found that other package failed. For the handrail, we utilised the Tekla Structures profile import tool so that we could take the timber profile directly from the manufacturer and develop the handrail in the model. Subsequently, the manufacturing data output from Tekla Structures could then be sent back to the timer manufacturer for them to fabricate to our exact specification saving time and unnecessary costs.

The project in numbers

- Steel stairs = 23 tonne

- Timber handrail = 173m

- Glass balustrade = 3 tonne