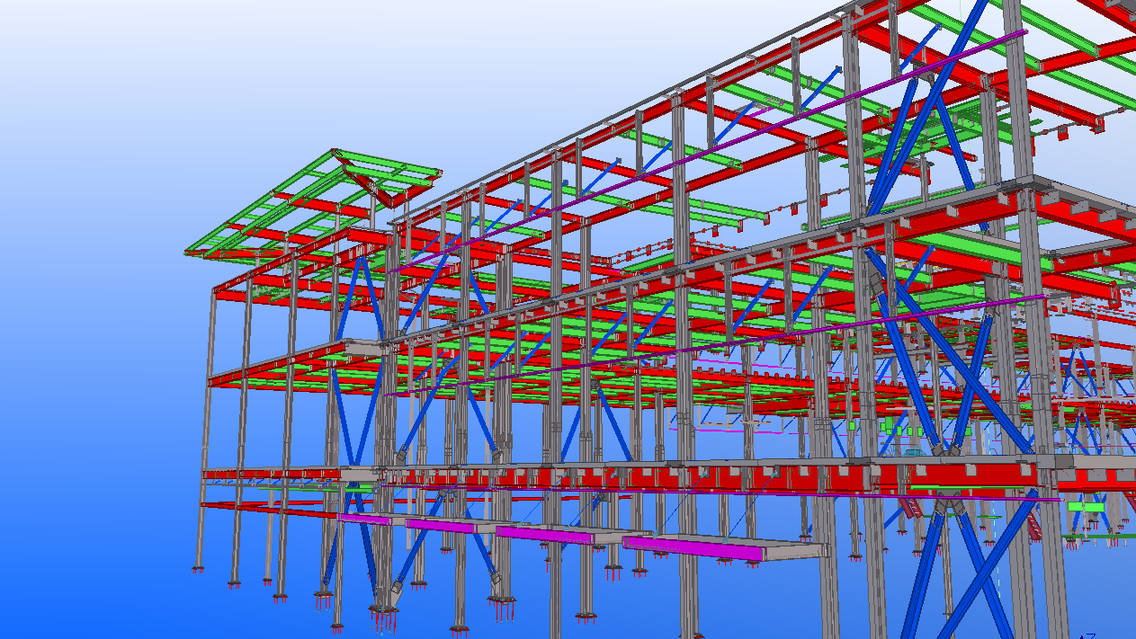

"Maryland Proton Treatment Center (MPTC) is a three story 110,000 square foot facility expected to treat 2,000 patients annually with the most advanced form of cancer treatment available, proton therapy. The unique treatment is highly precise and would target only the cancerous cells with radiation. MPTC will include five treatment rooms, patient and family lounges, medical offices, research facilities and ground level retail space. The estimated maximum price set for this project is $200 million. Building such a structure to house advanced therapy created the need for all shop drawings and equipment coordination to have pinpoint accuracy for the highly specialized proton treatment equipment. The project schedule was fast track and would not have been possible without the use of BIM file coordination between all parties and working in a 3D environment."

The limited construction space and 2 onsite tower cranes created a challenging work environment for the construction trades and in particular for the fabricated steel. Precise coordination was required between fabricator and erector who had to erect each truck load as it was unloaded.

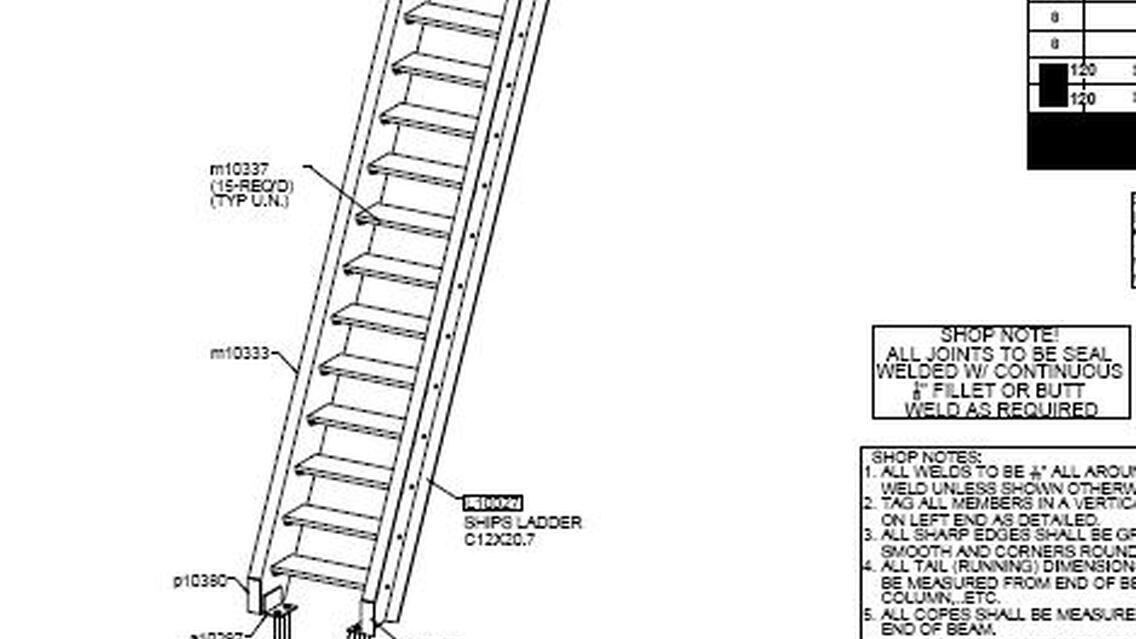

The success was due to close coordination between architect, engineer, fabricator and steel detailer with the use of the Tekla 3D model and various BIM files. The approval process was expedited by reviewing the detailers 3D model and marking any corrections or design changes to the 2D shop drawings.Connection or clearance issues discovered using BIM files for coordination were quickly resolved and delays avoided.