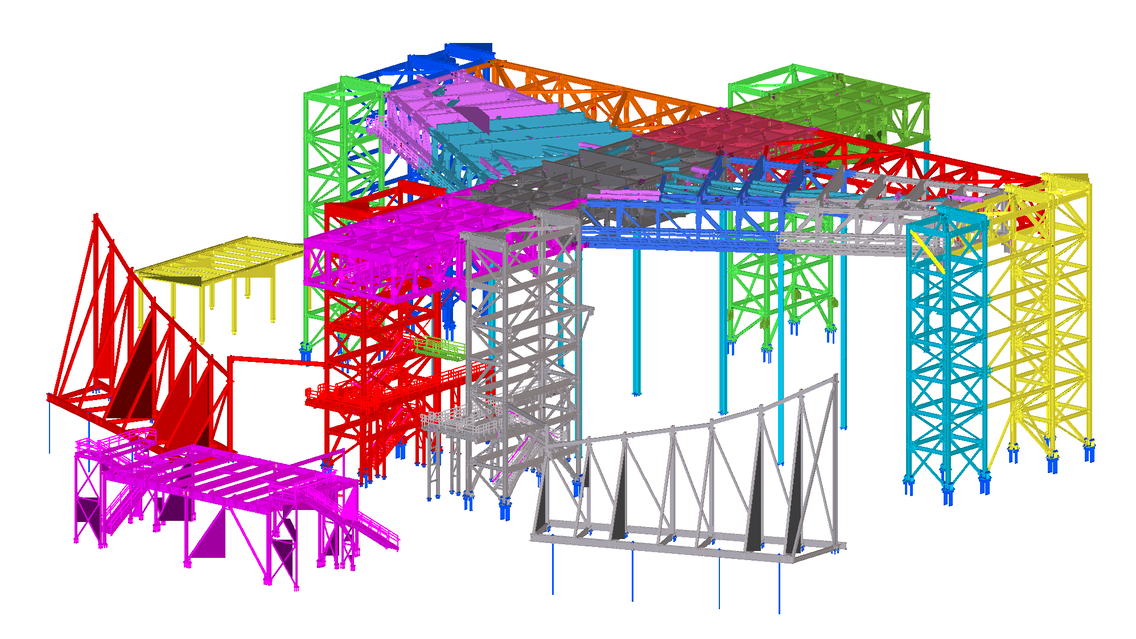

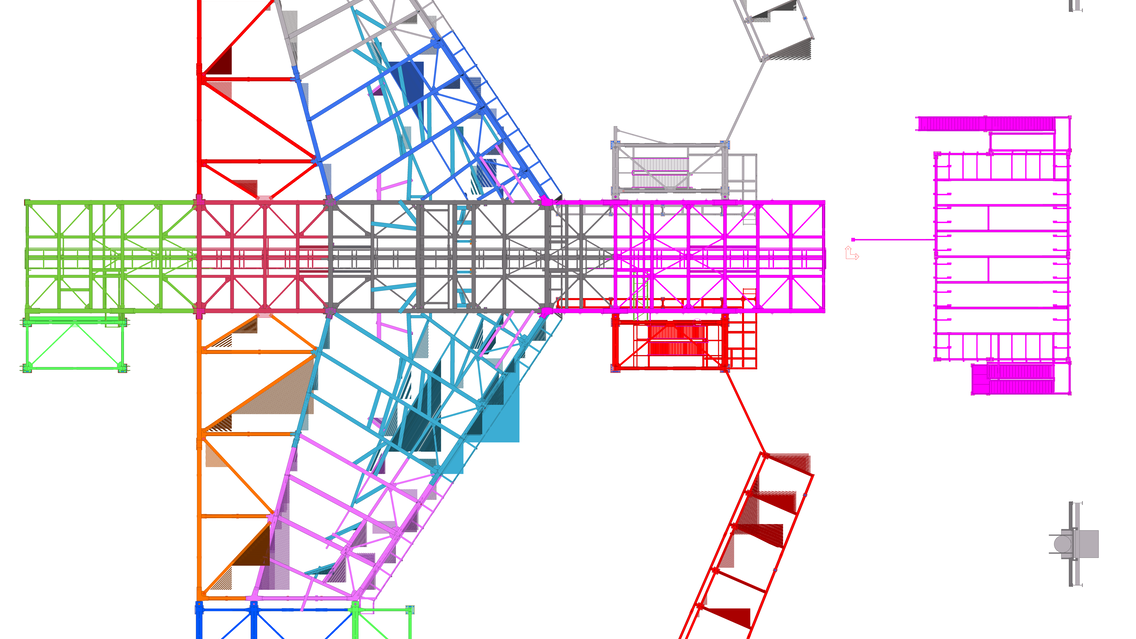

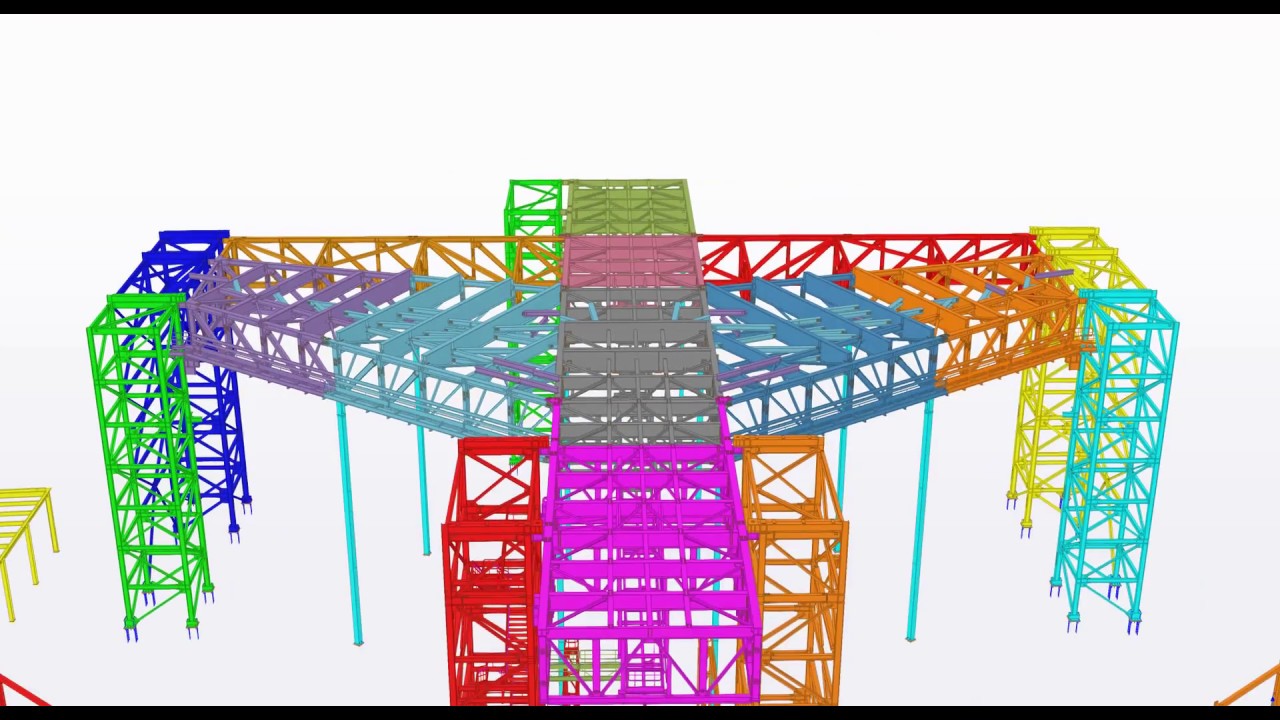

This project consisted of roughly 1400 tons and over 31,500 parts and was detailed in Tekla version 21.1. This project is for the new 777-9X plane for Boeing that will test the plane’s new capabilities for the next generation of aircraft for Boeing.

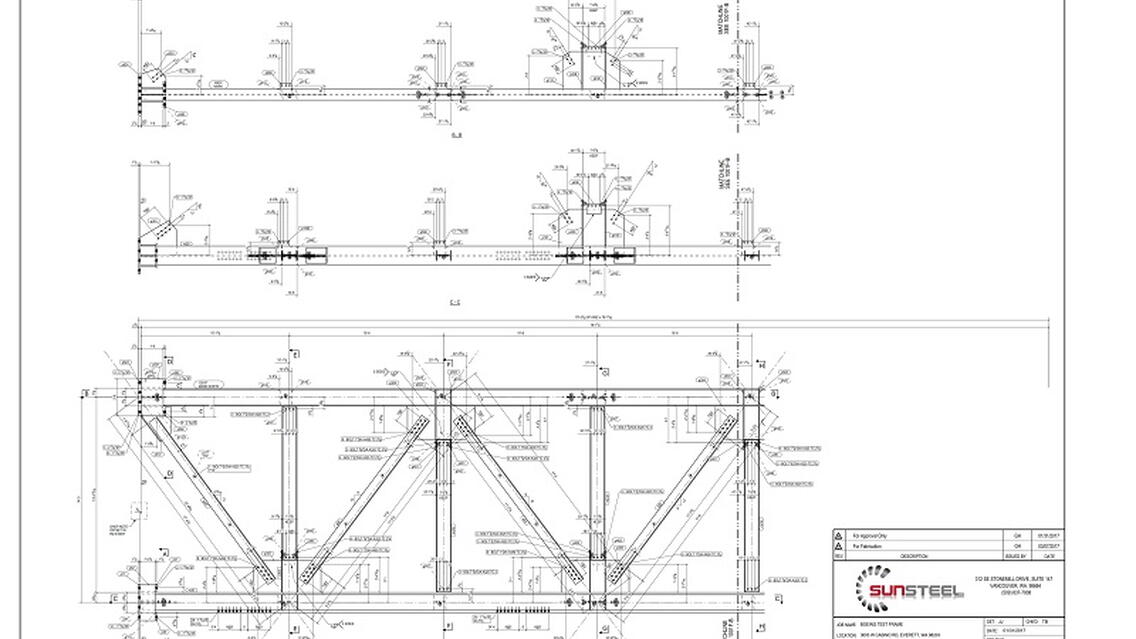

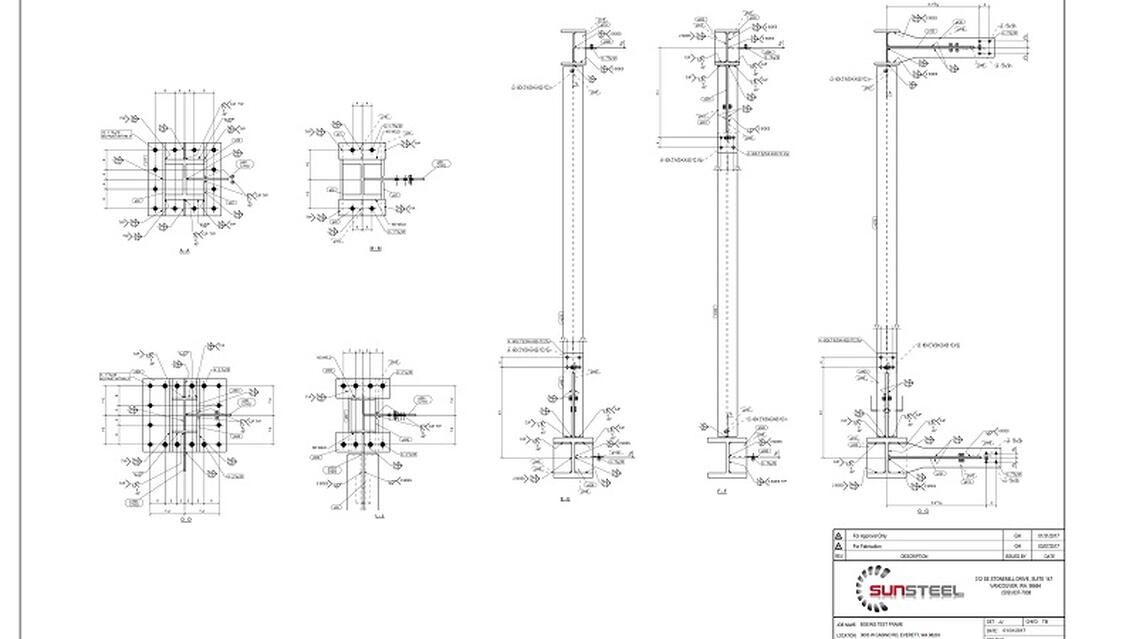

With 27 sequences and over 4100 shop and erection drawings, this was a complex project that included seismic connections, stair towers, ladders, gates, lots of rails, catwalks, trusses, box-trusses, horizontal and vertical bracing, and a cable pulley system that allows the main structure that takes on the shape of the airplane to move with the pulley system up and down raising and lowering close to 800 tons of steel at a time in support of the plane during it testing phases.

The schedule was 16 weeks from start of detailing to final fabrication release. By using Tekla Structures, the project required minimal shop calls and zero field calls or issues. At the topping off party, Boeing highly praised both the fabricator and the detailer for a job well done. The design team and all projects involved were able to work together to minimize changes and keep costs within the budget thanks to Tekla Structures. Some added changes that came up after the fact were incorporated into the project, but only added to the overall success of the project with the ability to make quick changes with Tekla Structures.