This project consists is a residential apartment tower located within the North Cape, a new and exclusive booming complex north of the city of Merida, Yucatan, Mexico. This complex will provide its inhabitants with different options of relaxation, lifestyle and entertainment venues a large shopping center called "Plaza La Isla Mérida" (the largest in the Southeast of Mexico). All of these venues are strategically located around a Main Lake which grants spectacular views throughout the day.

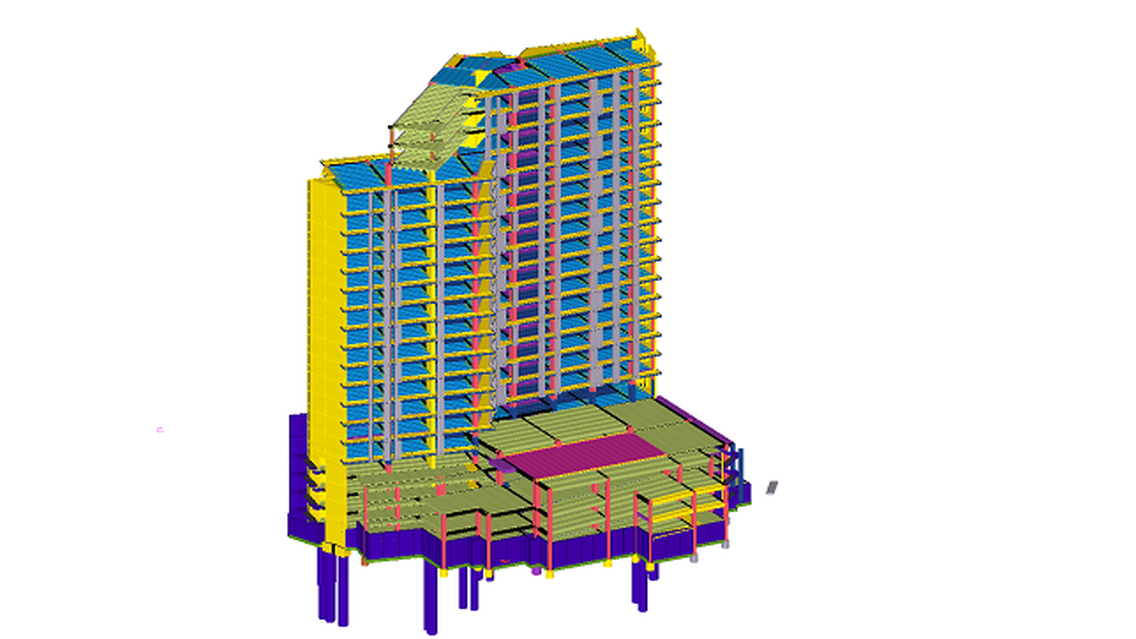

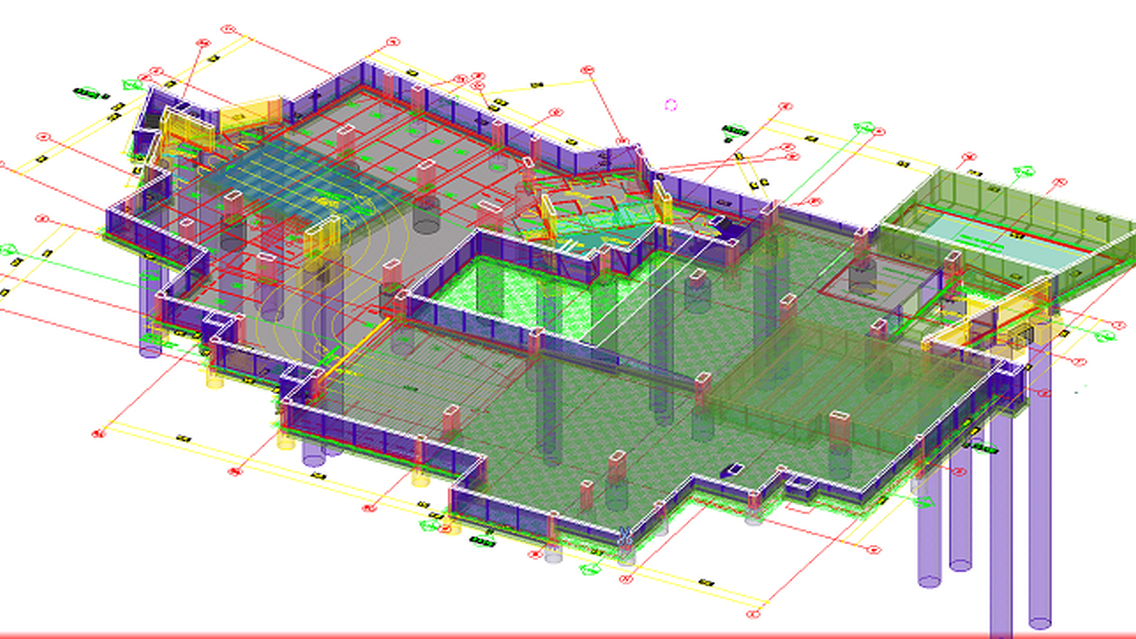

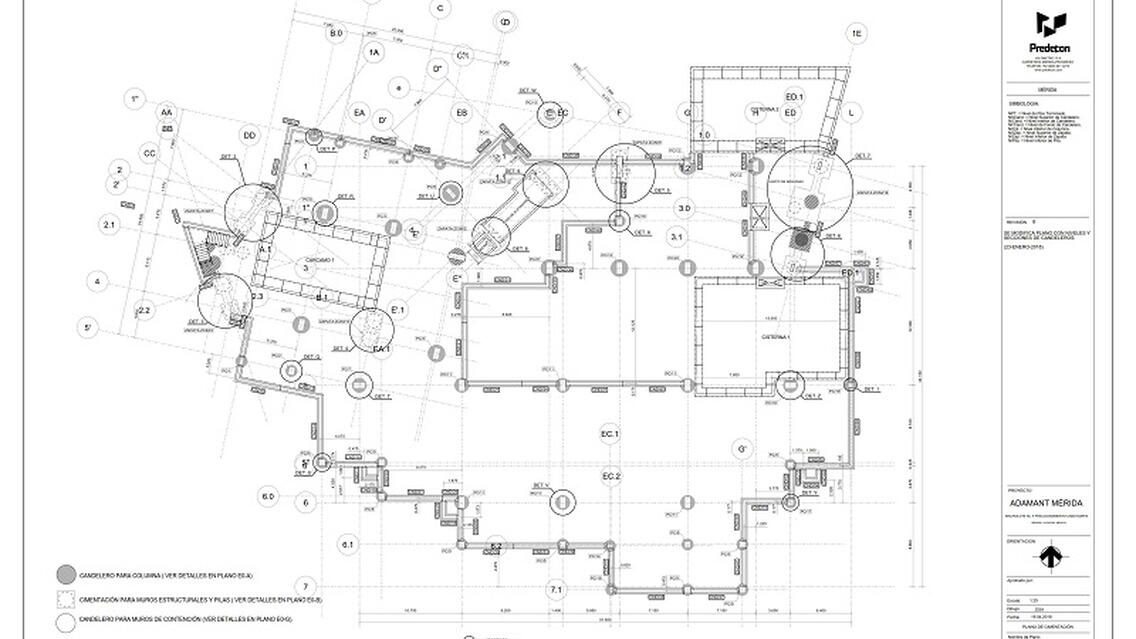

This project will be made with a combination of prefabricated and concrete elements cast on site. The foundation will be made up of long piles that anchor the building against the winds that are common in the region due to hurricanes and coupled with the hardness of the natural rock of the Yucatan Peninsula. The foundation cast on site houses connectors that have been designed to support the prefabricated structure. The elements such as beams and slabs are connected to the columns by means of gravity fittings calculated according to each case.

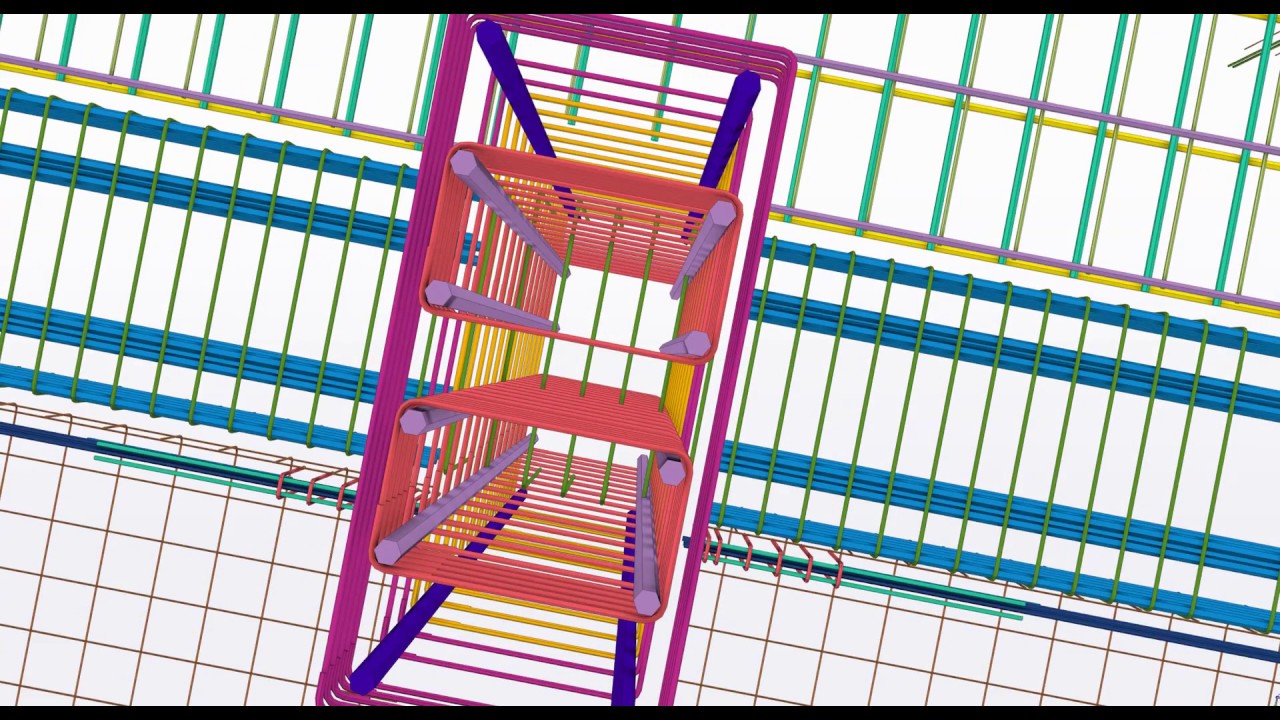

The architectural design included reduced heights between levels of the finished floors which explains why the structure did not allow big cantons of beams and slabs. This challenge was resolved by prestressed and reinforced elements according to each case. The second challenge in this project included the breakdown of the building according to the type of element. These elements were limited due to the assembly process, which was carried out by the use of a tower crane limited to the maximum reach of 8 Tons. Finally, the cutting of panels also proved to be a challenge as the process limited due to the reduced height between finished floor levels. The connections and assembly of parts were solved by creating some custom components.

To solve these challenges, Tekla Structures was used to model and detail complex connections between elements. Tekla Structures was also used to deliver the bill of materials, generation of custom components, and automatically updating plans according to updates in the model which enabled clear identification of elements for the manufacturing and assembly processes.