With Tekla you can:

Recommended products for you

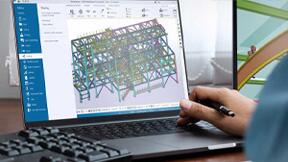

Tekla Structures

Structural design engineers, detailers, fabricators, contractors, and project managers can create, combine, manage and share accurate models for every project.

Learn more & try for free

Tekla PowerFab

Steel fabricators can systematically manage their entire fabrication process and enhance collaboration in the office and in the shop.

Learn more

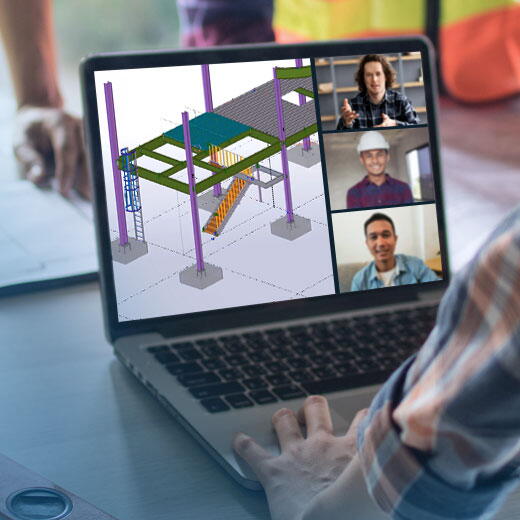

Tekla Model Sharing for Tekla Structures

Truly innovative BIM collaboration software enables Tekla Structures users to work on local copies of a model.

Learn more

Trimble Connect

Everyone involved in your project can handle truly constructible data with the Trimble Connect collaboration platform.

Learn moreLearn more about bidding and winning

We are here to help you

Find your local Tekla contact or send a request for us to contact you.