Located close to the centre of Barking, this scheme provides 78 new Pocket homes for local, first-time buyers. Arranged in two blocks, the proposals address a busy road to the west and a quiet residential neighbourhood to the east. As part of the design, they have introduced a new public, pedestrian route linking the two and giving access to a pair of secluded courtyard gardens for residents.

Each of the new blocks are built using off-site construction, reducing disruption for neighbours and improving the quality of the finished homes

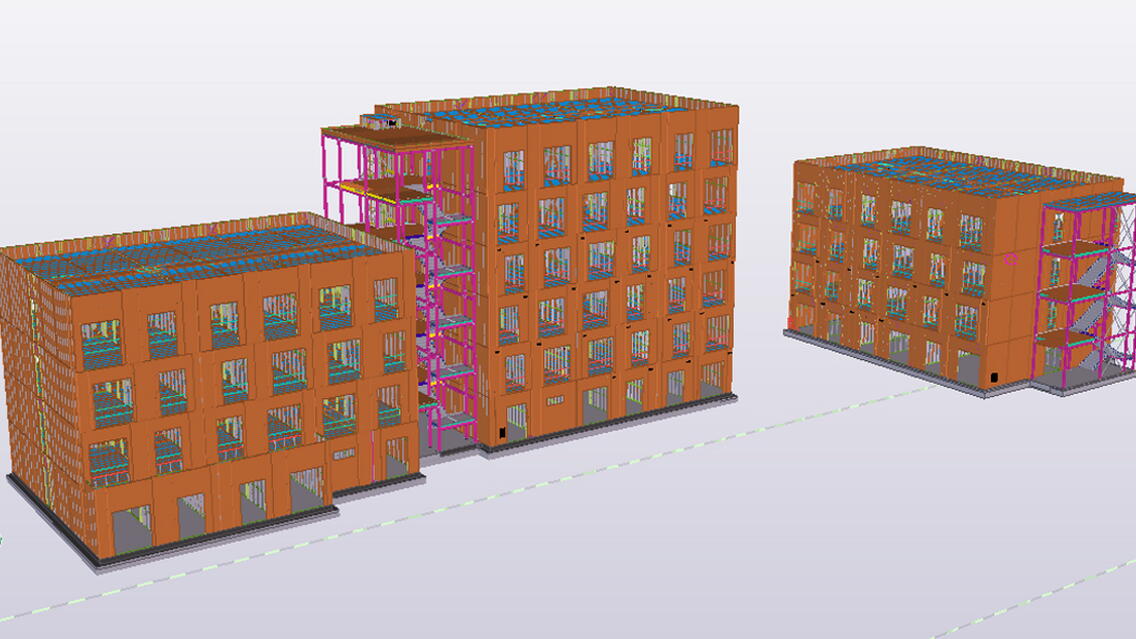

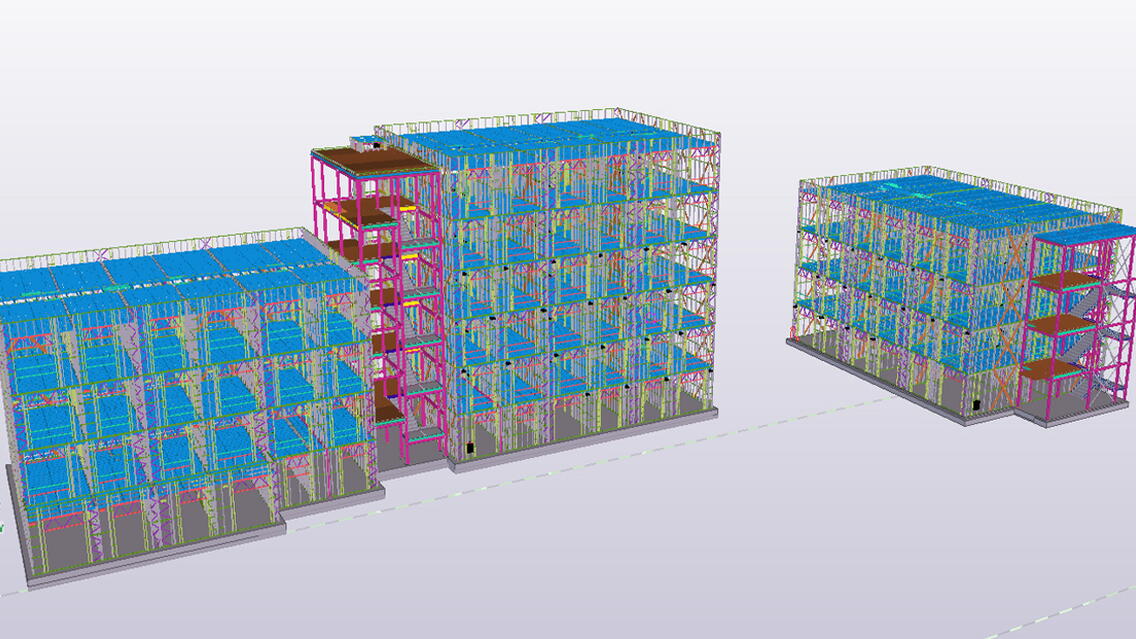

The main blocks are 95% light gauge steel panels manufactured off site utilizing modern methods of construction which greatly reduce the waste and increase productivity whilst also being energy saving, with the remaining 5% being integrated hot roll sections fabricated locally to our factory. The floors were installed at 1 per week, using our own edge protection system we were self-sufficient as we did not rely on scaffolding. The wall panels were delivered pre-boarded with CP board and the floor cassettes pre-boarded with 18mm OSB, effectively giving a weathertight structure as soon as possible allowing works to continue inside and out on the lower floors as the building progresses skyward.

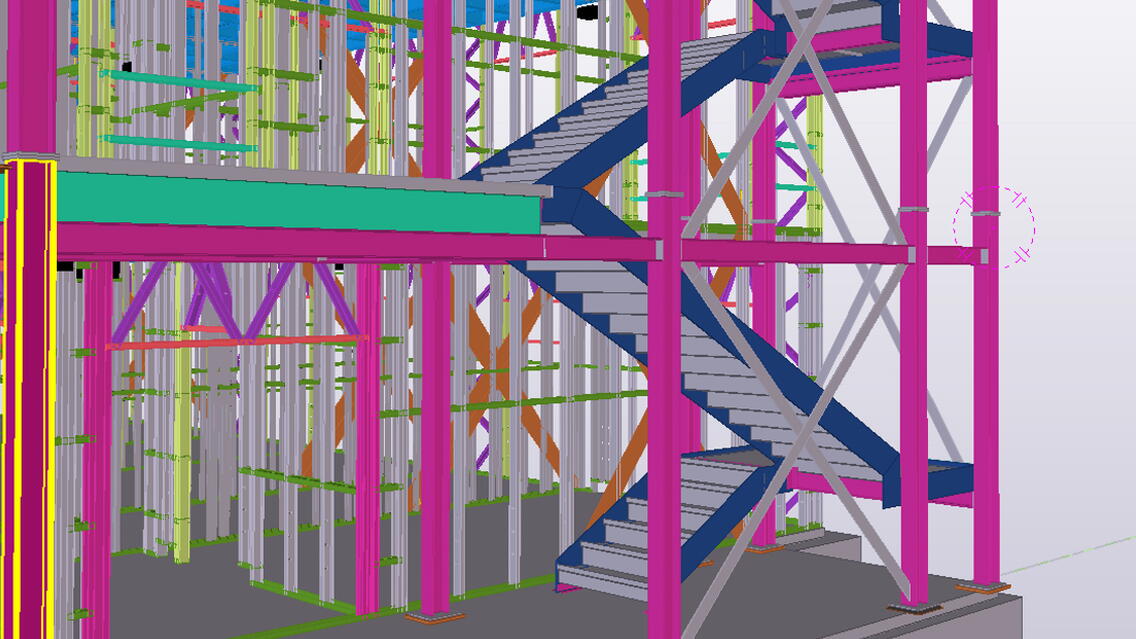

The stair cores are predominantly a galvanised hot roll structure with light gauge steel floors, designed to be practical yet architecturally pleasing.

The scheme needed a building solution that would deliver both pace and innovation. Shaylors approached Intelligent Steel to design, manufacture and construct the 4 & 6 story blocks using off-site manufactured light steel frame (LSF) technology.

What were the challenges and what made the project successful.

Due to the time constraints on this particular project on both design and manufacture, it was highly important we were able to utilise Tekla combined with the knowledge of our designers to ensure a positive outcome was achieved. To enable this to happen the phasing tool within Tekla was used to its full potential to help reduce deliveries. This ensured efficient batching of deliveries in coordination with site access and construction sequence, allowing for quick, efficient and flexible installation. Also, by phasing elements it allowed us to issue material into manufacture to co-ordinate with deliveries which ensured all material was ‘racked and stacked’ ready to be issued to site.

Being able to utilise more resource within the same model through the implementation of model share was also a beneficial factor for this project as we were able to continue processing one block into manufacture whilst finalising the design on the other block, which allowed us to stay within the programme timescales.

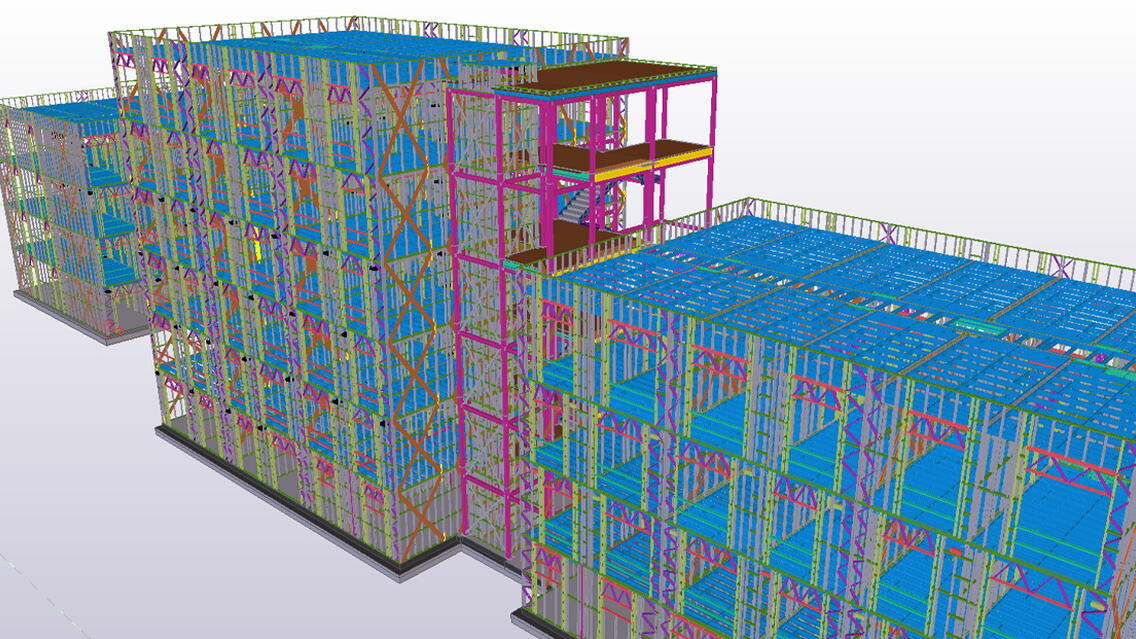

To help reduce site time, panels were modelled incorporating external board, not only did this give the client a visual of the structure to be delivered, but the information was also easily exported and passed to manufacture to minimise factory waste and increase efficiency of material ordering, providing a pre-determined bill of quants of raw material for purchasing and programme optimisation. This also contributed and resulted in an effectively weathertight structure as soon as possible. Hot roll elements which included two stair cores were also detailed in Tekla and integrated into the cold rolled loadbearing design. This allowed the client to see how both structures would be constructed alongside each other and how the interfaces would interreact together.

From the initial design inception, the client was given access to the Tekla model, which was used for the coordination of interfaces between the light gauge steel and other construction contractors such as M&E. The user friendly software, compatibility and various visualisation techniques allowed practical integration of other services as a timely cost-effective process. This also allowed the client and other disciplines to review and check the steel frame model against their models to ensure no clashes occurred.

The success of completing design, manufacture and installation all within the required timescales, came from using a highly engineered product, using advanced CAD/CAM techniques. 3D modelling and BIM was used to ensure quality transpired through each stage of the project, from initial design through to efficient, right-first-time installation.

What benefits utilizing BIM and Tekla Software brought to the project.

Using Tekla from project inception to create the structure was highly beneficial when it came to delivering accurate models and meeting the client’s brief:

- By importing reference models, the margin for error was reduced. This allowed the design process to flow more easily and ensure the client’s expectations were met with fewer revisions to the design.

- Having the ability to create IFC models enabled quick and easy sharing with the necessary people. This was beneficial as it kept all parties up to date with the current model, enabling effective clash detection and collaboration on any queries or design developments.

- Due to the size of this project, it was important to have confidence that the tools used could cope and manage with the large volume of data – the use of Tekla was key to gaining this confidence. Furthermore, having an element of repetition between floor levels, Tekla enabled us to store and re-use commonly used components saving time throughout the design process.

The use of Tekla as bespoke 3D modelling software and BIM, married with the use of a bespoke CAD/CAM interface to our roll forming machines, allowed the fully detailed design to be exported straight from design to manufacture. The pre-engineered solution was designed, manufactured and assembled on-site with confidence, creating a highly impressive building that exceeded the project expectations of both the client and main contractor.

The project in numbers

Roughly: 180 tonne of cold rolled steel, 38 Tonne of hotroll