Transforming a 1970s office scheme

The South Bank Tower development by CIT in London has allowed the dramatic transformation of an unoccupied 1970s office scheme into state-of- the-art, luxury apartments in the heart of London.

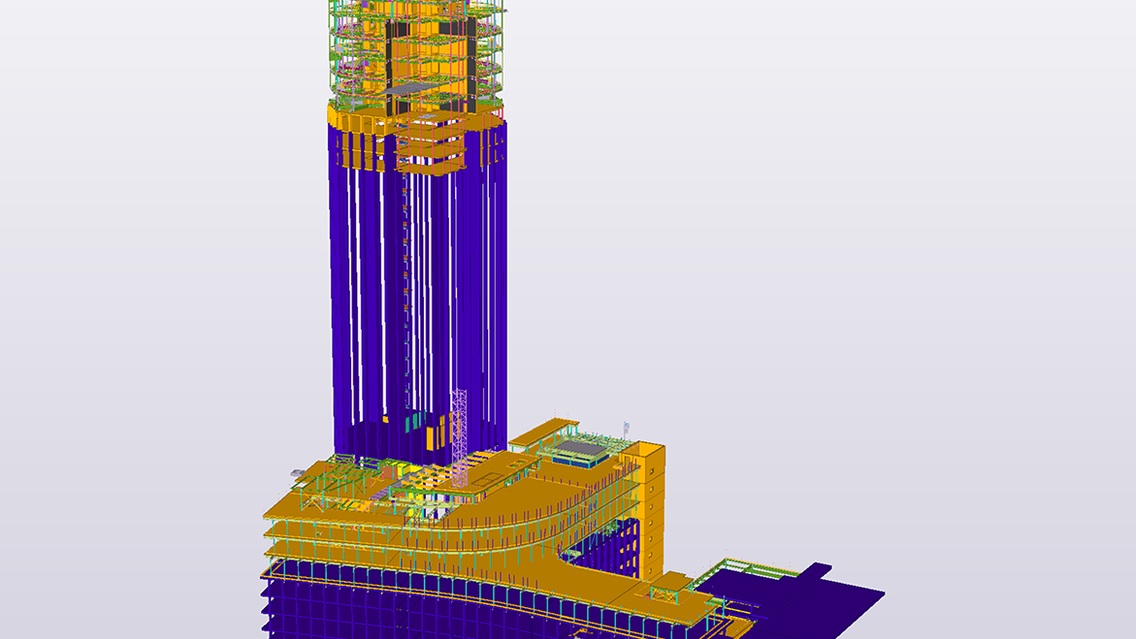

The existing development, typical of its time, featured an eight-storey, low-rise podium building and adjacent 30-storey tower, both constructed from reinforced concrete frames.

A very restricted city centre site with limited space for expansion, other than vertical, involved the construction of additional floors onto the existing tower and podium structures, creating 191 high-end luxury apartments, 370,000ft² of office space and 72,000ft² of retail space.

Using structural steel framing, the podium building was extended by two floors to accommodate many of the residential amenities within the apartment complex with the main accommodation located in the refurbished and extended tower building.

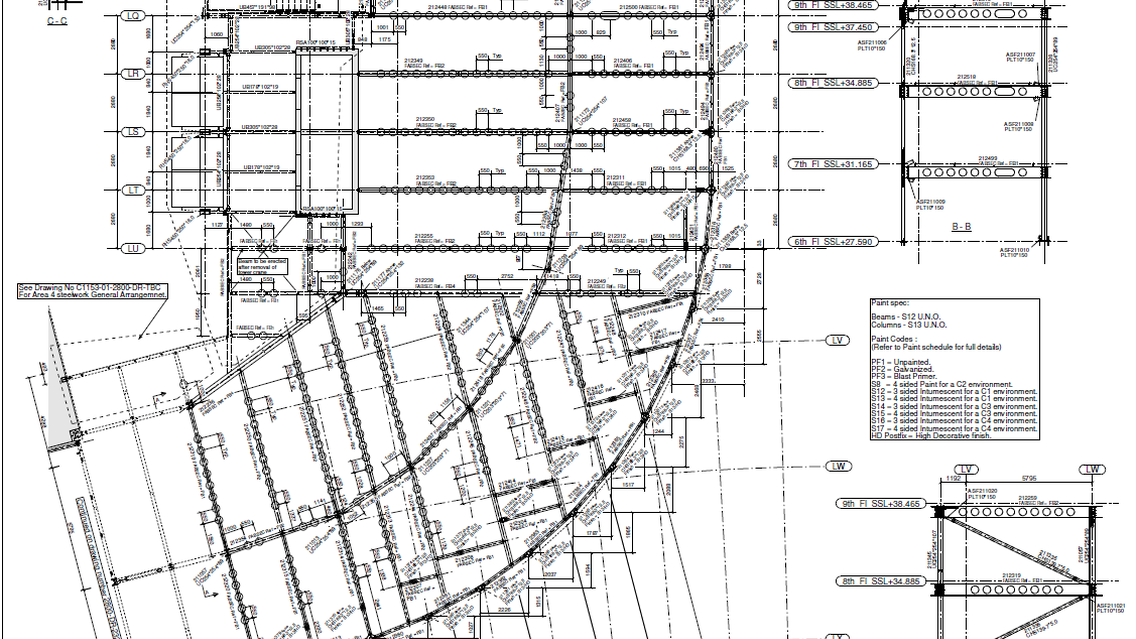

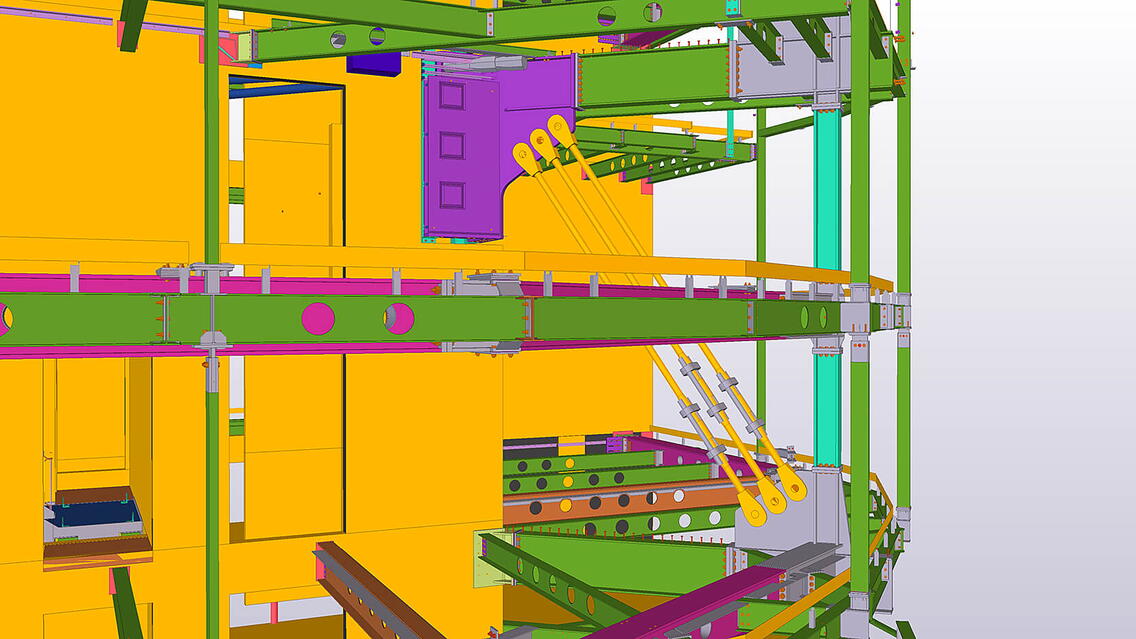

Due to the limited load carrying capacity of the existing structure the 11-storey extension of the tower was, in effect, hung from the extended central core using a combination of a tension bar system and cantilevering steelwork in conjunction with lightweight concrete floor slabs. A feature of which, was the use of solid steel billet ties between floors that provided a slim profile to integrate with the lightweight glazing system maximising the breath-taking views across London.

Cast-in connections from the steel tension hangers to the core extension in the tower were both critical to the overall structural design and complex to install on site. They were partially fabricated off site and then finished in-situ by site welding and needed to be detailed in conjunction with the core reinforcement, prior to connecting the tension bars.

Tekla avoids hitches on-site

Subsequently, the tendons were tensioned in-situ and used to raise the lower three levels of steel off a temporary support frame on the existing tower roof. To ensure this operation went without a hitch, at some 30 floors up in the air, elements of the jacking and tensioning gear were modelled in Tekla and coordinated with the final details. Many other bespoke fabricated sections were needed to satisfy floor depth restrictions, which required bespoke steel section profiles to be created in the Tekla Structures software

The use of Tekla to model and coordinate most of the site operations played a major part in the success of the construction of this project. Not only was the lotting facility used to assign load order to the Tekla model but also the model went through another process. The detailed member assemblies were arranged for best fit into bespoke cradles. These could be lifted from the lorry trailer on arrival at site directly to the point of construction, on what was a restricted access site in the very centre of London.