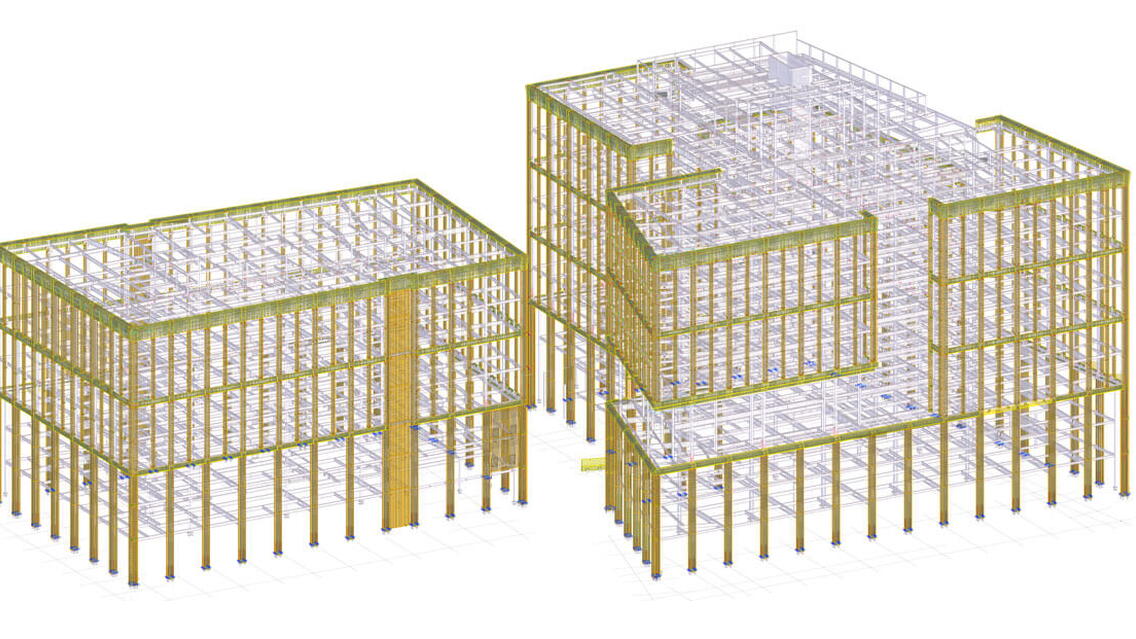

Situated on the banks of the River Lee in Cork, Penrose One & Two is a commercial development constructed by Hegarty Construction and designed by Wilson Architecture. The buildings enhance the emerging skyline at Cork’s docklands and deliver 250,000 square foot of sustainable, Grade A office space.

Situated in close proximity to the historical Penrose House, the buildings designs are based on classical proportions with the intention of embracing and enhancing their historical neighbour. Techrete was awarded the tender to design, manufacture and install the architectural precast concrete cladding façades for both buildings at Penrose Dock.

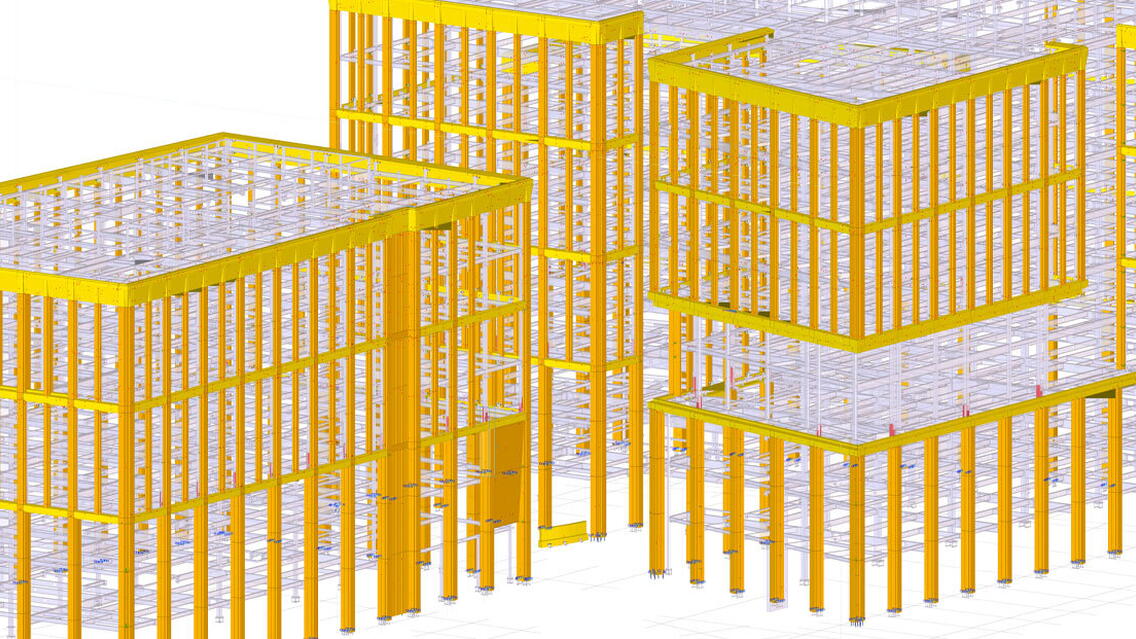

Penrose One is organised in three distinct vertical modules with Techrete’s double height vertical mullions elongating the building’s appearance. Structural precast concrete columns rise from ground level to the third floor, cast in three parts and stitched together, creating a grand entrance to the building and further elongating its appearance. The precast concrete façade of Penrose Two also consists of mullions and spandrels and the consistency of both façades provides a framing approach to the original Penrose House.

The chosen mix for the project was Techrete’s C190 with an acid etched finish, with provides a warm soft appearance to the façades. Cast-in lettering was used on panels for Penrose One and Two providing elegant signage for the two entrances.

What were the challenges and what made the project successful?

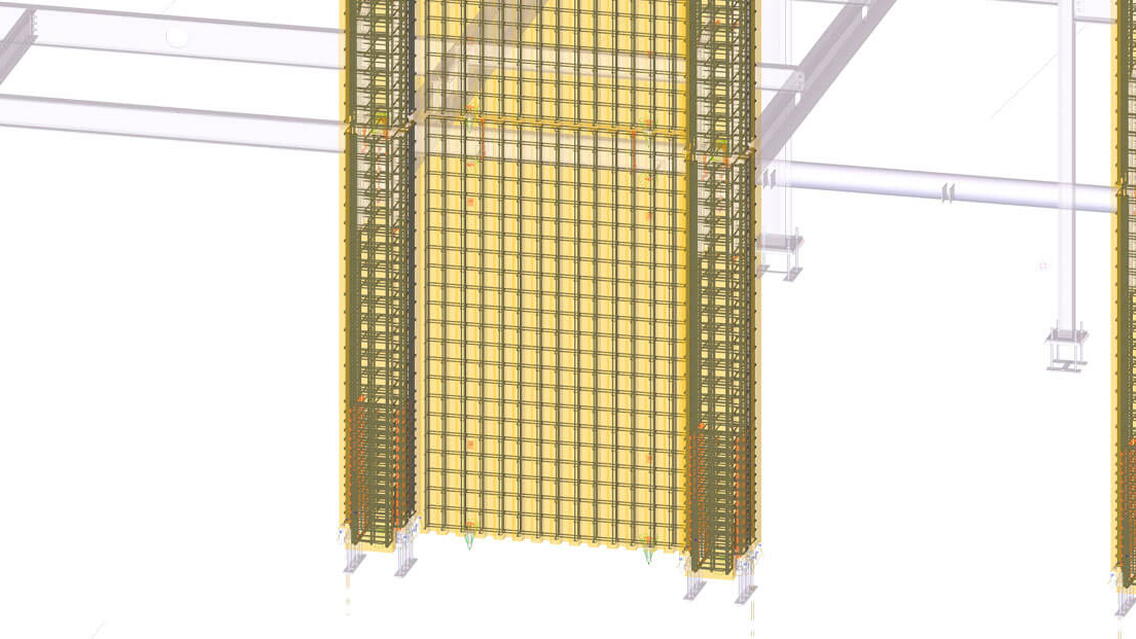

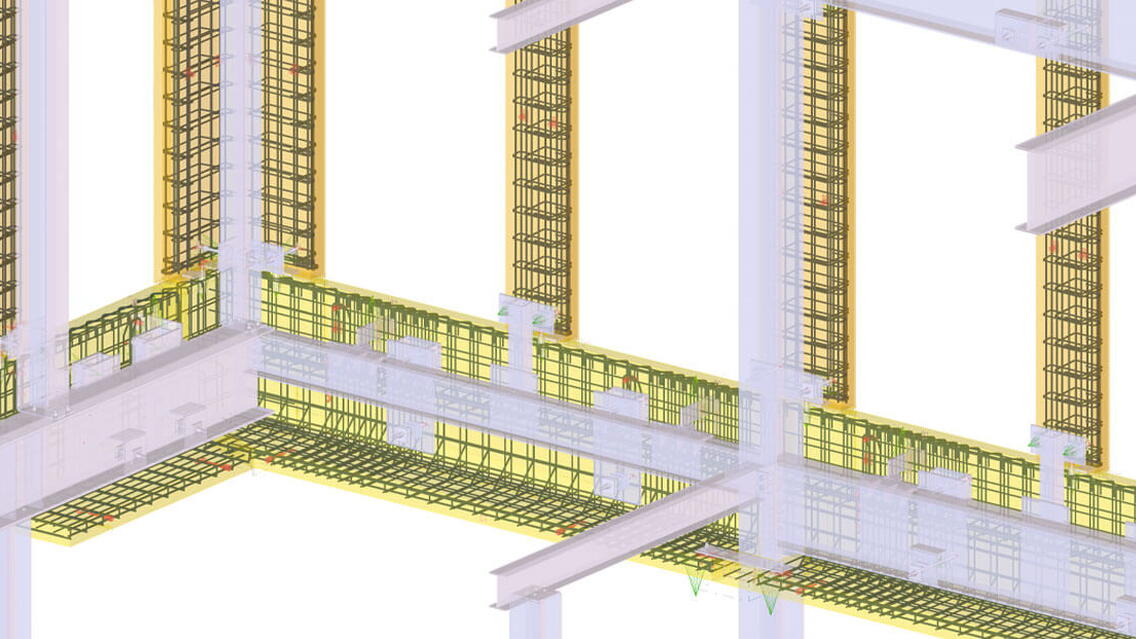

As this was our first job as a company to model the reinforcement for each unit and create BVB files, we had to liaise with the company that made our EVG machine for cutting and bending the reinforcement to get an update for the machines. We also had to adjust the lengths that Tekla rounded off the cuts to, which is default set to nearest 25mm for the BVB files. We also has to adjust the bending head radiuses for the reinforcement. The complex shapes of some of the units also lead to difficulty in modelling the reinforcement for some of the units. We also had to take the lead in getting other subcontractors to set up and use the project base point for coordination.

What benefits did utilizing BIM and Tekla software bring to the project?

Improved coordination and clash detection - Co-ordination with other contractors (steel frame, fixing locations, structural model etc.) greatly reduced the amount of clashes when the job went to site.

Tekla was very useful for quantifying the amount of reinforcement that was needed and also used on the job.

Better collaboration and communication - Sharing the model with all disciplines allowed a better visualization of the project from planning, installation, manufacture, costing, engineering design & architectural design.

The increased reliability of a coordinated model leads directly to greater building quality.

Overall the project was very successful for everyone that was involved and Tekla had a major input into this success.

The project in numbers

- Overall value of project to Techrete = €2.2m

- Steel tonne = 471t

- Total number of architectural precast concrete cladding manufactured and installed on Penrose Dock = 939 which covered 9,008m2

- Length & width, Penrose One = 32m x 50m wide and 32m high

- Length & width, Penrose Two = 62m x 60m wide and 38m high