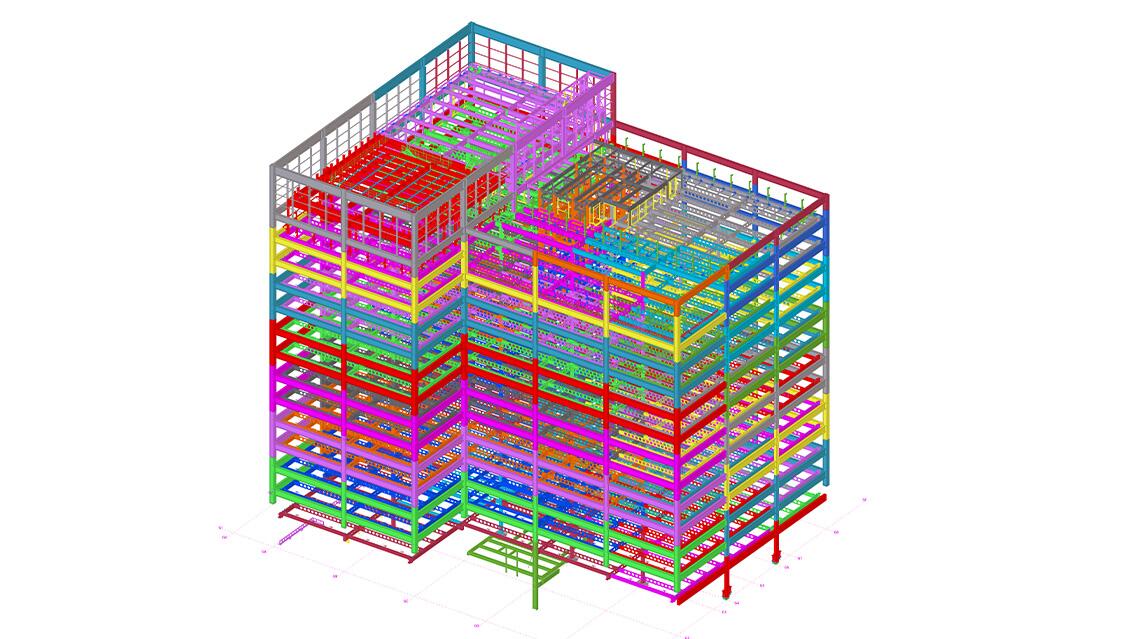

One Centenary Way is the first building within Phase 2 of the major regeneration project of the Paradise Circus area of Birmingham City Centre. It's one of the most sustainable buildings within the West Midlands.

One Centenary Way has a number of below-ground constraints, mainly the A38 Queensway Tunnel, which runs directly underneath the building. As a result, the building couldn't have a normal load-bearing core or columns coming into the ground to hold the building up. This makes the project one of the more elaborate buildings (spanning over 280,000ft2) due to its striking black exoskeleton frame that acts as the main source of stability for the building.

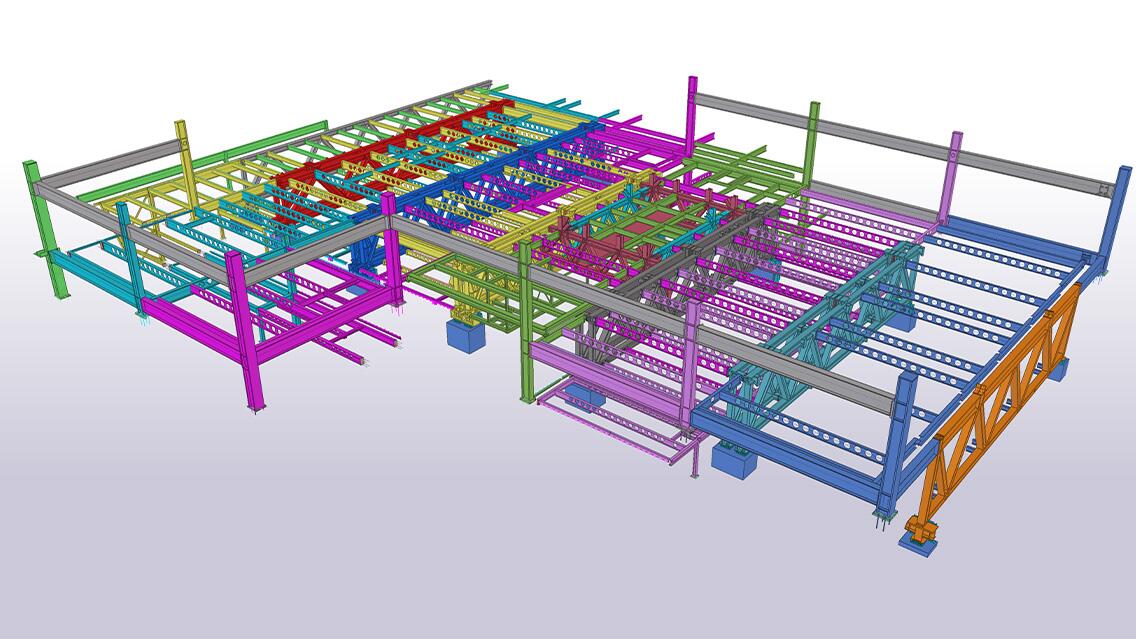

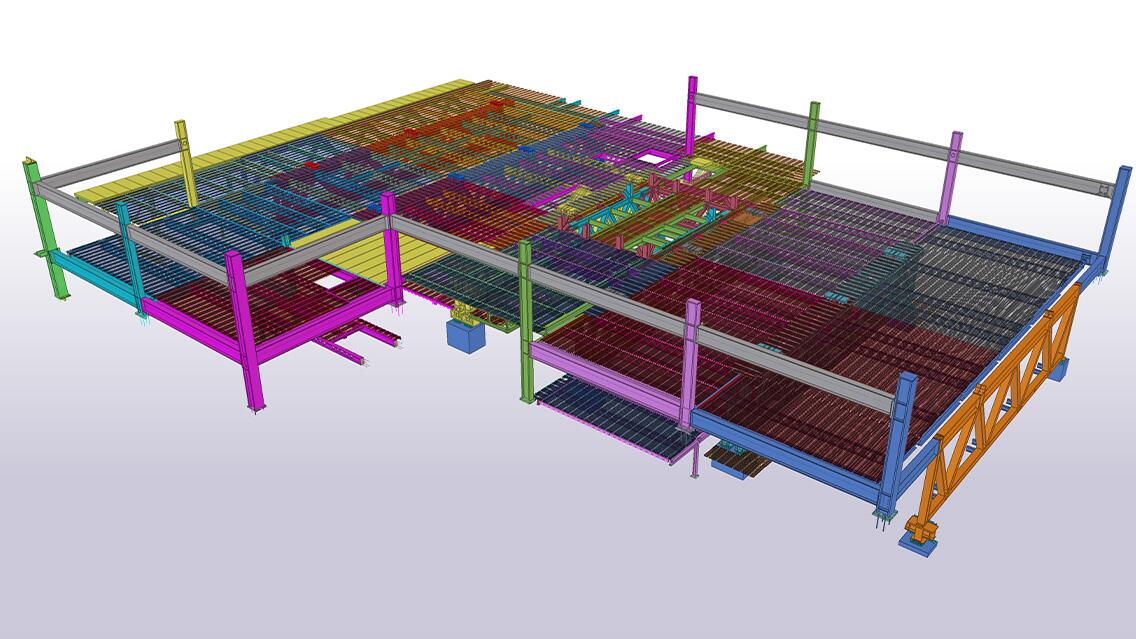

Sixteen trusses, totalling 1,156 tonnes (part of the B2 Structure), are among the largest ever designed and constructed in the UK for a commercial building. The enormous trusses form the foundation and podium level of the building which will act as a table for the rest of the building to be constructed upon.

The sixteen trusses ranging from approximately 30m long and 6m deep were transported to site as fully welded assemblies. This was a significant part of this project due to the prior research that had to be conducted, and liaison and communication with various authorities. A 1,200-tonne mobile crane with a full reach of eighty-nine metres was used to lift the transfer trusses, the largest of which is 34.6 metres in length and 5.2 metres wide. The heaviest truss weighs in at 119 tonnes.

We used Trimble Clarity to combine our Tekla Model of One Centenary Way with Google Earth, to illustrate what the structural steel frame would look like when erect.

Key challenges:

- 1156 tonnes of trussed to span over the live A38 tunnel

- Transportation ranging 28 tonne and 120 tonne

- The exoskeleton frame

- The building has a non-structural core

- Movement joints for thermal expansion joints

Key successes

- Delivery of the B2 transfer structure

- Saving on programme with the full welded assembly

Benefits of using BIM and Tekla software

By using BIM and Tekla Software we were able to coordinate with the cladding contractors and MEP Contractors as well as Engineers and Architects. Consistent communication across all areas of the project allowed for a smoother production.

Important points or benefits:

- BHC supplied, fabricated, and erected 6,286 tonnes of steelwork and installed over 34,000m2 metal decking to form the 13-storey mixed-use building

- 16 trusses totalling: 1,156 tonnes

- Largest transfer truss: 34.5 metres in length and 6.15 metres wide

- The heaviest truss weighs in at: 119 tonnes

- Precast stair flight: 68No.

- Precast slabs: 52No.

- Barings:24No.

- 1200 tonne mobile crane with 89m reach used to lift the transfer trusses

- Trimble Clarity used to combine our Tekla model of One Centenary Way with Google Earth