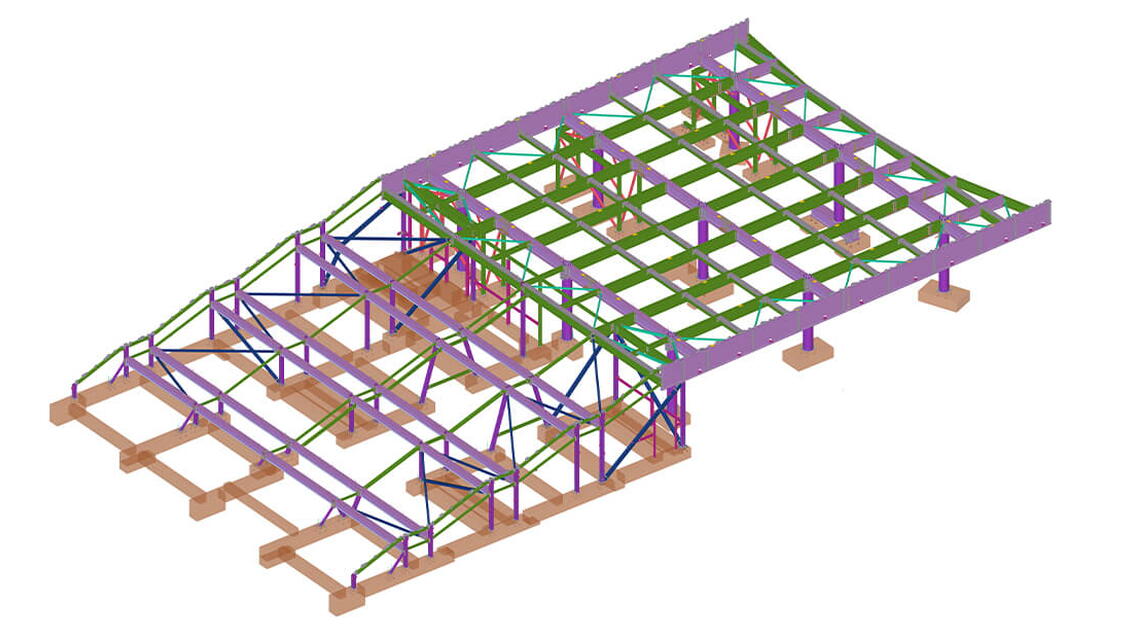

Hillcrest are thrilled to present the structural steel frame for the Olympic Way steps renovation to Wembley football stadium. The existing concrete ramp has been demolished and replaced with a feature staircase leading to the stadium entrance. Being the nations home stadium, we are honoured to have modelled, detailed, fabricated and erected such a prestigious project.

What were the challenges and what made the project successful?

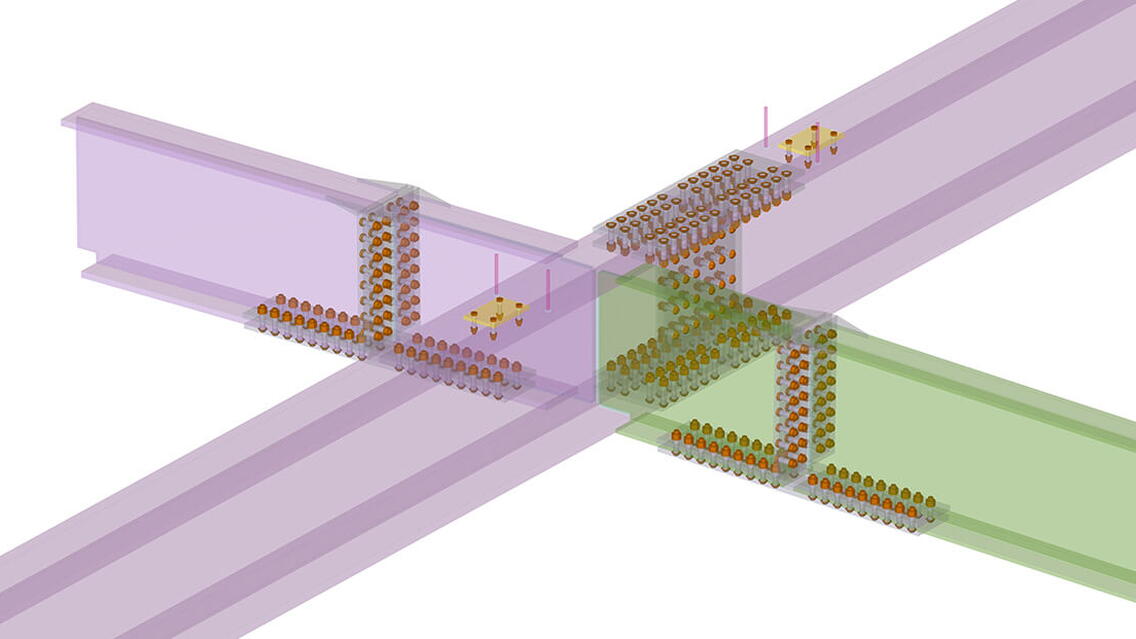

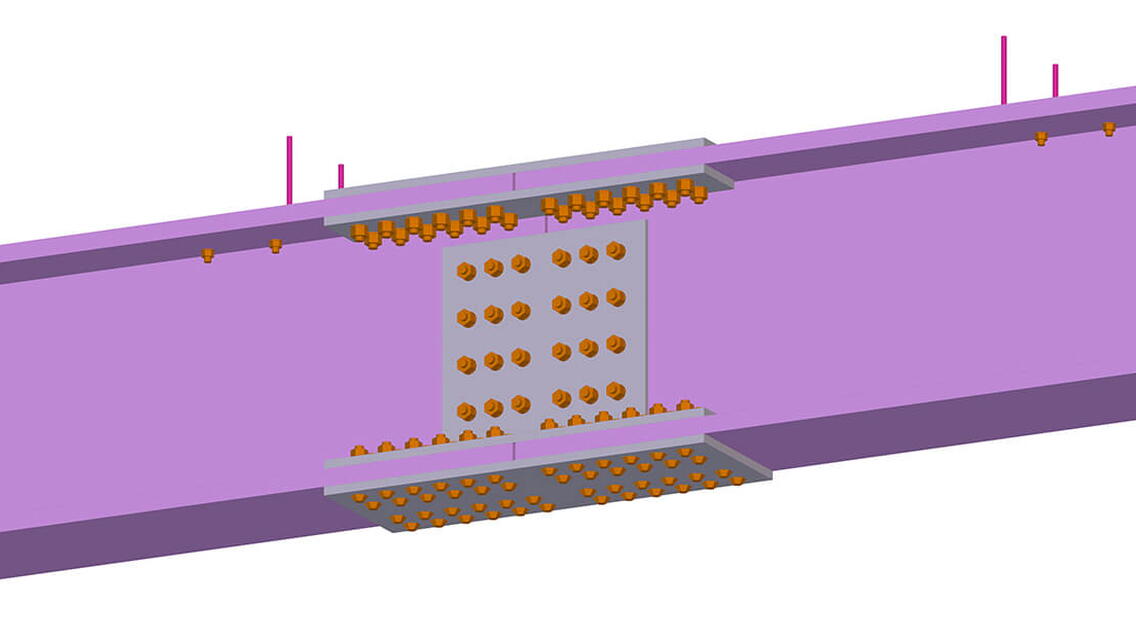

The structure utilizes 38 meter long fabricated beams along the length of the structure, standing 2 meters deep and weighing 14.6 tonnes per spliced assembly. The detail, fabrication, transport and erection of these members caused unique problems that required innovative solutions to solve.

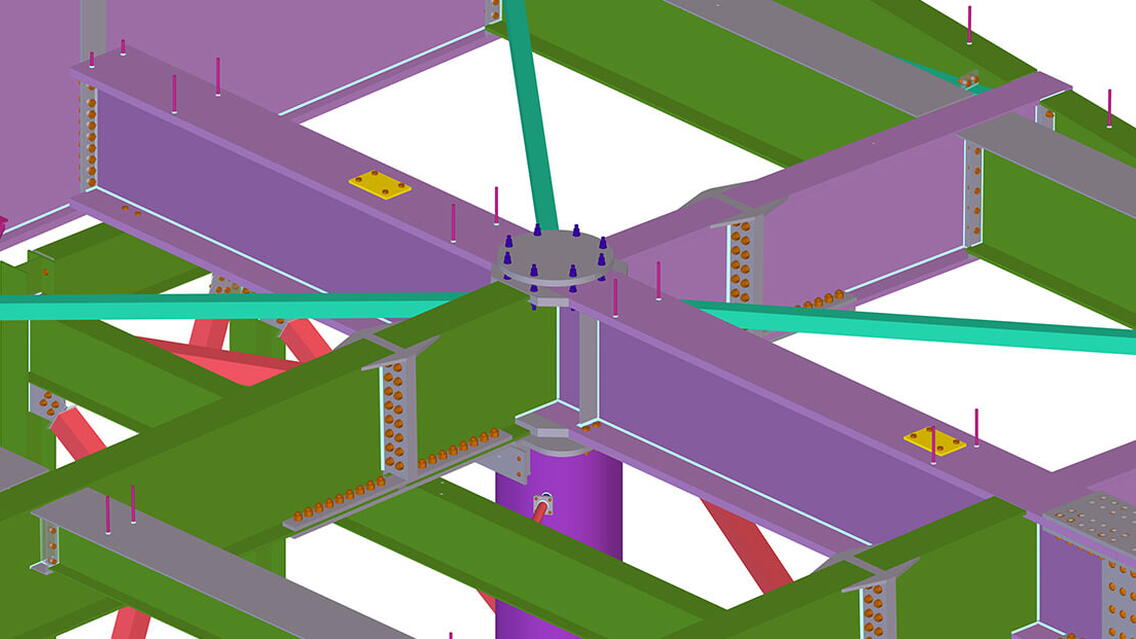

Adjustable lamppost bases were integrated within the structural frame which had a large effect on the connection design and detailing. Welded stubs to large fabricated sections and immense splice connections were exercised as a result.

BIM coordination was a large part of this project, more-so than others we've worked on. The BIM procedures followed by all sub-contractors were a key factor to the overall success of the design. High detail 3D models and survey data were supplied by all contractors, providing refence models for everything from handrailing, existing structures and pre-cast slabs. Regular meetings took place to review clash checks between the models and offer opportunities for sub-contractors to evaluate the progress of the project thus far.

The project in numbers

- The design was for the footfall of 80,000 people on the steps at any one time.

- 38 meter long fabricated beams along the length of the structure, standing 2 meters deep and weighing 14.6 tonnes per spliced assembly.

- Value - £1.75m

- Tonnage - 427 tonnes

- Assemblies - approx. just over 900 No.

- Size 69.5 meters long, 36 meters wide and 8m tall