With advances in technology and the associated ability to extend the productive life of existing mature gas reservoirs our client, Shell, have been going through a series of upgrade projects throughout the Southern North Sea to extend the life of many of their existing gas platforms. One such platform is the Leman Alpha installed in the late 1960’s. Pinnacle Consulting Engineers were engaged in early 2016 to structurally design and detail, in collaboration with Shell and their team of specialist contractors, two new I-tubes to be installed within empty conductor guides from the platform’s cellar deck to sea bed. These new I-tubes were to house cables to the seabed forming part of an Impressed Current Cathodic Protection (ICCP) system to extend corrosion protection, and thereby the serviceable life, of the Leman Alpha jacket structures.

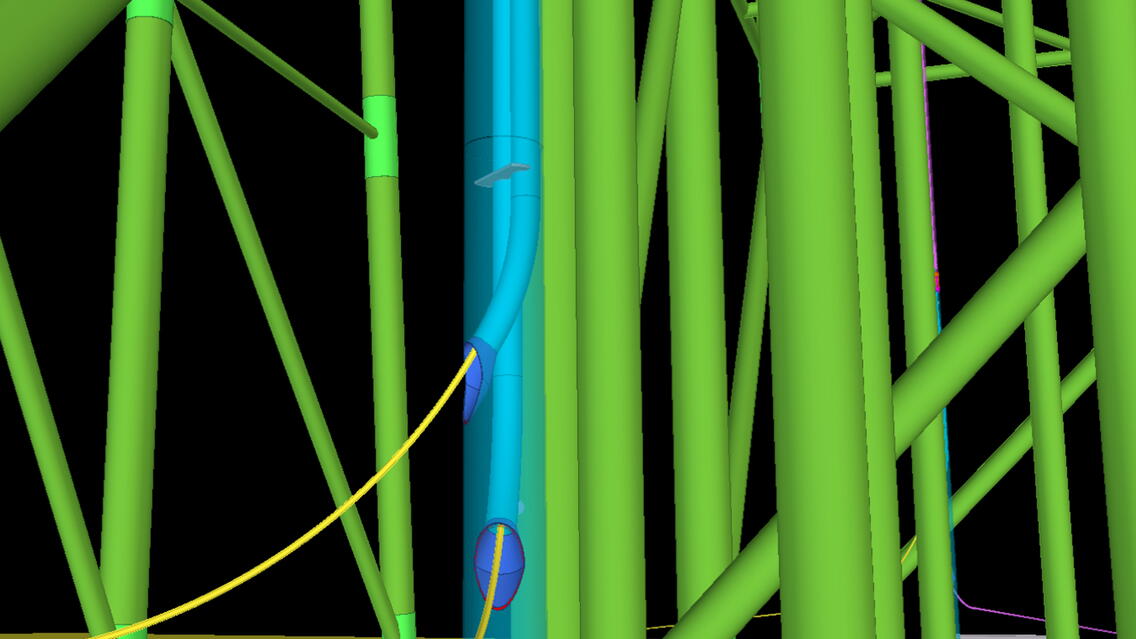

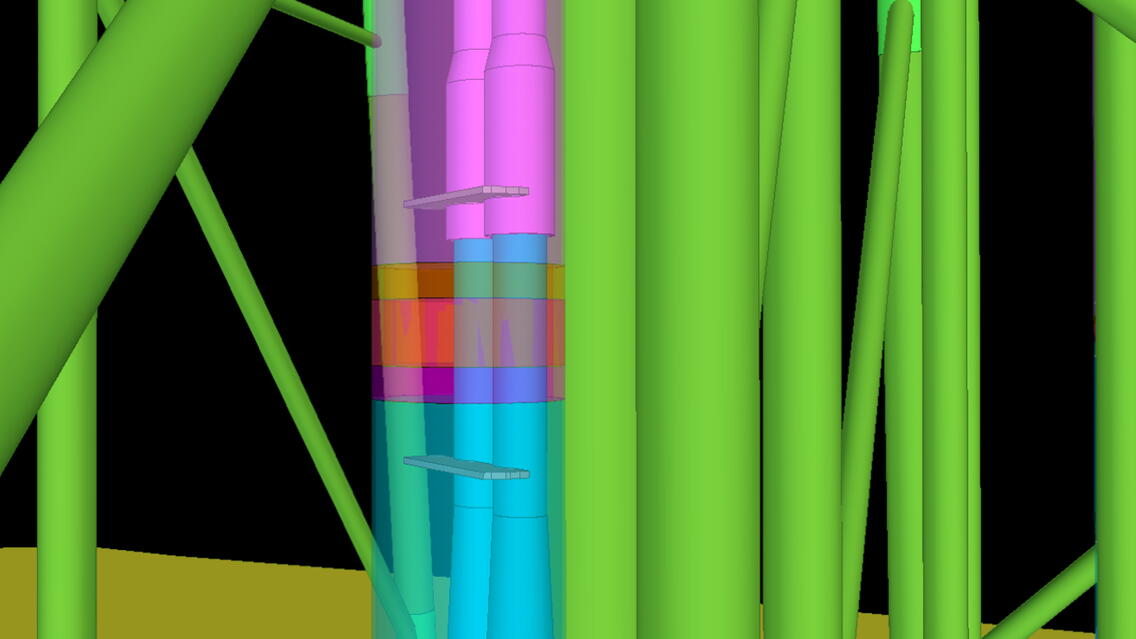

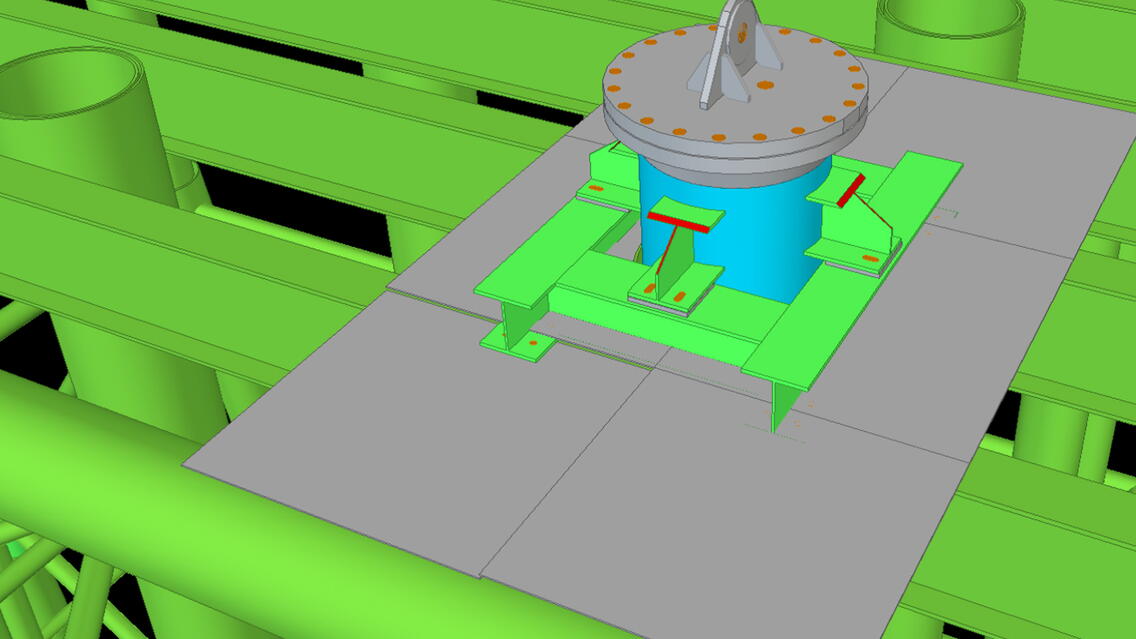

The ICCP process involved installing three Retrobuoys (a 500 Amp ICCP Anode Sled) on the seabed and connecting via power cable to the jacket structure. In order to protect the primary cables as they journeyed up to the platform deck level, two new 610mm diameter I-tubes were installed within two of the spare Conductor Guides, one each on the North Side and South side of the platform.

In each of the 610mm diameter tubes two new 210mm diameter, tapering to 168mm diameter, internal J-tubes had to be installed to allow messenger lines to be dropped from the Main Deck level to sea bed and then be retrieved by a ROV (Robotic Submersible) in order connect to the main cables which then had to be pulled up to the platform deck. These internal tubes had to keep the ICCP cables separate, and avoid any snagging whilst the main cables were being pulled up using a specialist pullhead mechanism. (Figure 1 shows the overall arrangement of Tubes within the sub-sea jacket structure)