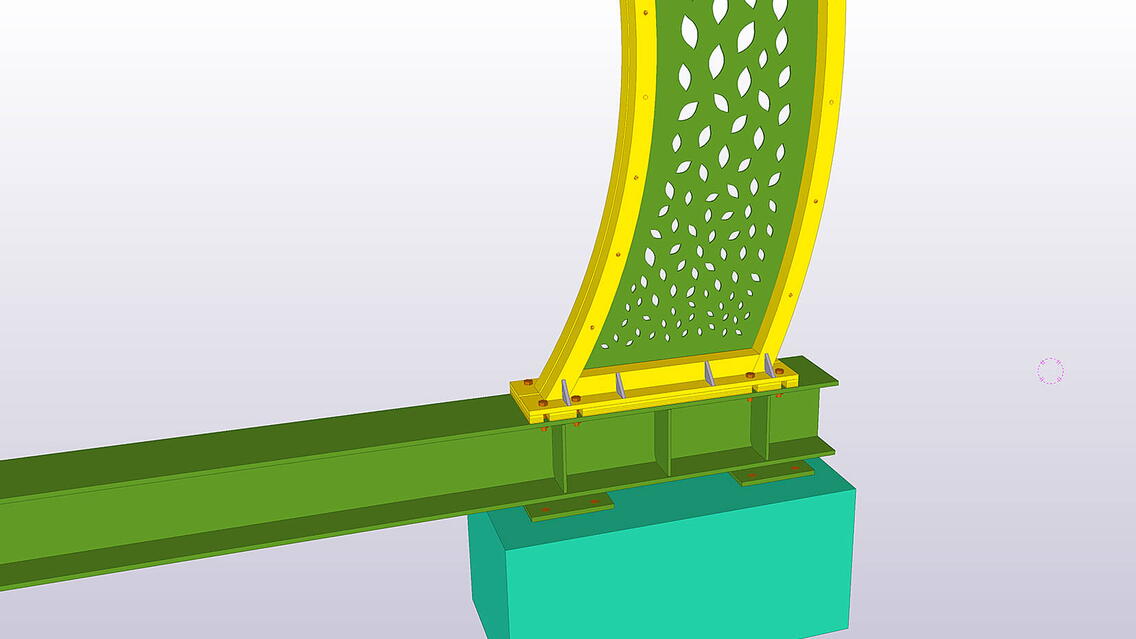

Intricate horseshoe entrance welcomes park goers

The horseshoe archway, approximately 3 metres high and 3 metres wide, is the entrance archway to The Horseshoe Park. The infill on the archway is 5mm thick corten steel, cut into three sections to aid manufacture and installation. The main frame comprises two curved SHS sections, which connect either side of the corten plates, with a SHS section running around both edges to create the horseshoe effect. Which dome head bolts are used to assemble the structure, but also to give the impression of tacks on a horseshoe.

Initially basic set out dimensions were issued. As changes throughout the project were likely, Tekla seemed the most appropriate software package with its 3D aspect making modifications easy.

Time saving technical features from Tekla

Working closely with metal fabricator The Metal Works to make manufacture as easy as possible, various connection designs were issued before a final connection pin was decided. Tekla’s 3D model view made it extremely easy to visualise and talk through any design queries that arose during the modelling phase.

The modelling was done using different elevations on the archway to ensure that it fulfilled the correct parameters, both vertically and horizontally. Polybeams made this much easier following construction lines and circles set out, ensuring the archway was within allowed tolerances.

Mathematical calculations were carried out to ensure the fixing pins were spaced equally, but also line through from on the outer SHS section to the inner SHS section. Naturally the spacing of the inner SHS section connection pins holes was closer because of the smaller radius. Copy Rotate ensured that the bolt spacing was central around the SHS and equal, as it offers the facility to copy around the centre of the radius. Tekla modelling ensured that the holes located through all appropriate materials on the fabrication drawings are in the correct place and, once fabricated, will fit together correctly.

Although the archway looks largely simple, there were much less tolerances allowed for to ensure that it all went together and to provide the best finish possible. The intricate parts that were modelled, took a lot of setting out and cutting to ensure that the archway was even and cut outs in the corten were all central, this was done by calculating each radius that the different parts are located along, which are all slightly increased through the archway moving closer to the top, with smooth, laser profiler produced edges.

Drawing in Tekla was much easier than comparative software and time saved was considerable. Similarly the software produces collated lists showing all materials and bolts, including quantities and specs.

Cost efficient NC file creation

Due to the complexity of the corten plates, The Metal Works outsourced these to a laser profiler with TDS producing the NC files in Tekla. This saved time for TDS by not having to detail each aspect of the corten profiles, also aiding the fabrication phase, as the laser profiler did not have to reproduce the drawings for the cutting machines.

AutoCAD was also used within the project to produce the text outline, as this was specified to be in a certain font and size. Tekla’s ability to interoperate these DWG drawings enabled the letters to be created as a 3D section that could be cut into the corten steel plate to the correct dimensions and font.