The Gatwick Airport Station upgrade was undertaken to improve the facilities within the station, specifically addressing issues with overcrowding and to improve the passenger experience, while also ensuring additional capacity for future growth. It was a critical requirement for the project to try and deliver these works while maintaining near normal operations for the passengers using the station.

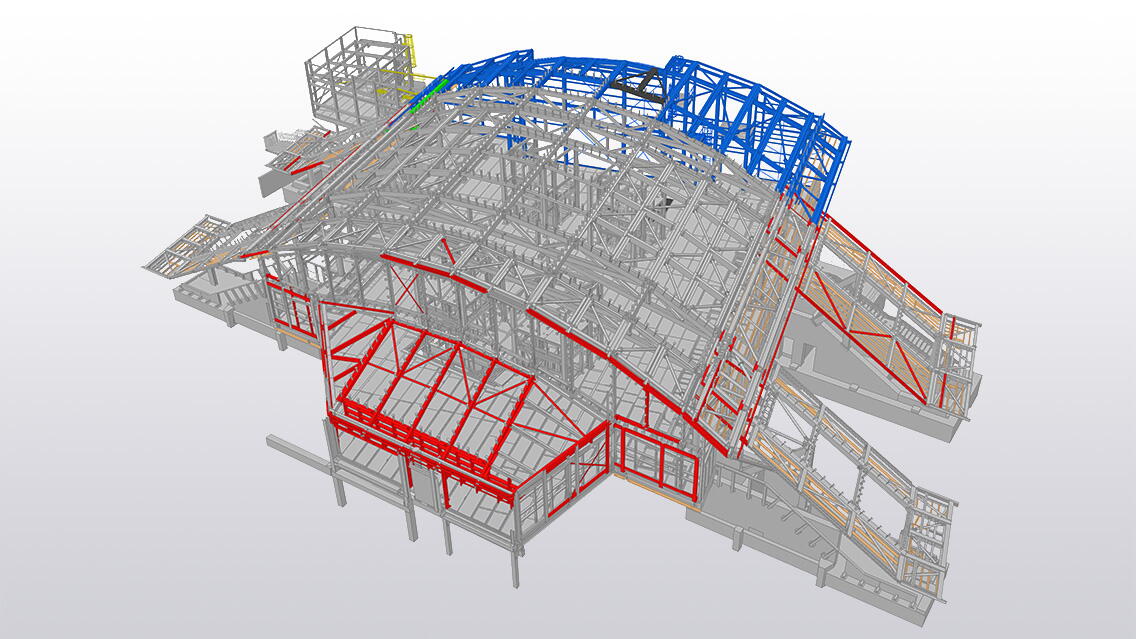

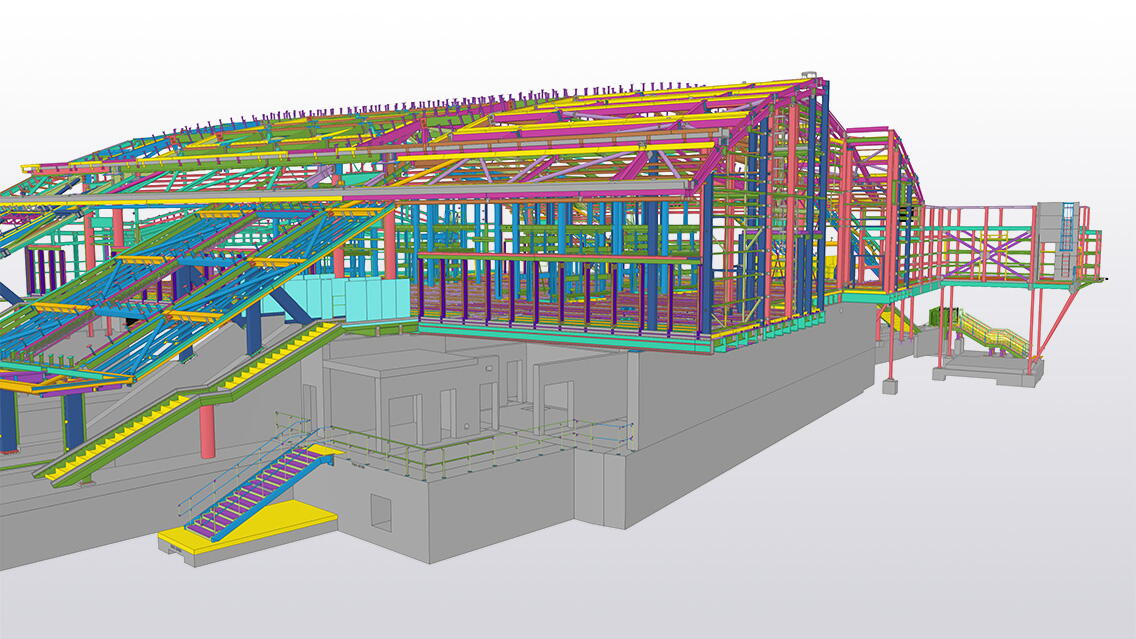

One of the key components of the Gatwick Airport Station upgrade was the expansion of the existing concourse, which had to be built over the top of four existing live tracks and platforms. This required the maximising of all DfMA opportunities, extensive advance coordination with MEPH and Finishes, while also ensuring full integration with existing structures and services.

Kilnbridge Construction Services were tasked with delivering three structures within the scope of works, collaborating with Costain, Systra, Emico and others to deliver the project successfully.

Challenges and achievements

The challenges on the Gatwick Airport Station upgrade project were extensive and ranged from practical, to access, to geometrical. The main overarching challenge was the severe spatial constraints on the project, meaning that virtually every component had to arrive on the project for direct installation.

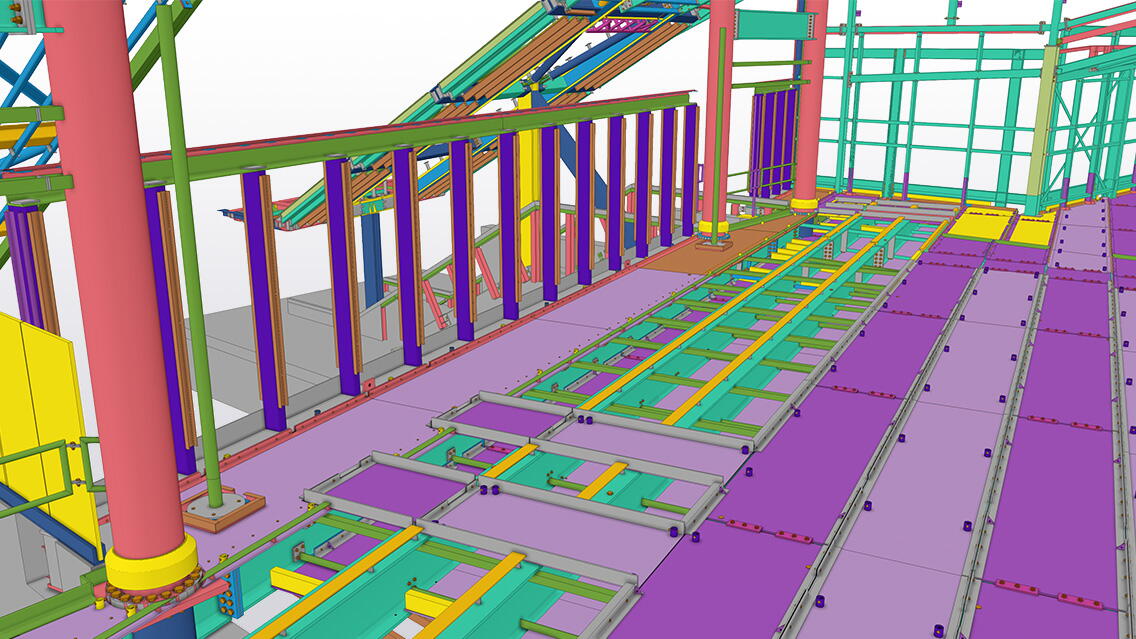

There was very little opportunity for retrofit work to take place once installed, due to the operational railway. In practice, this meant that Kilnbridge Construction Services needed to maximise the amount of work completed on all components off site through a number of ways:

- Ensuring exact build sequence management.

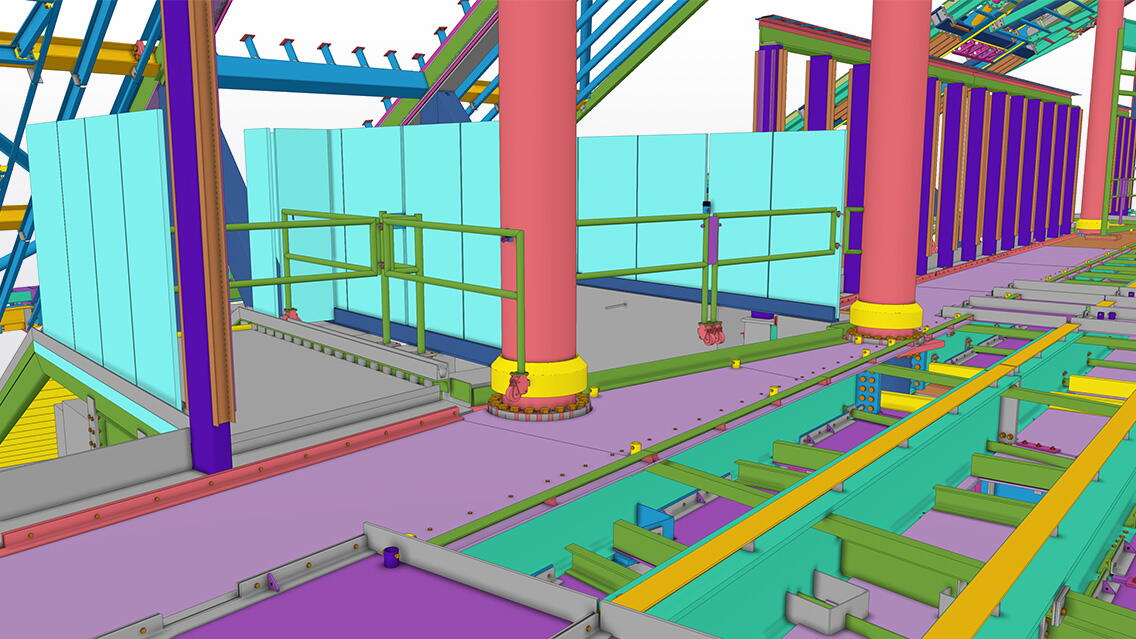

- Extensive coordination and allowance for cladding and MEPH support structures and penetrations, to ensure they were fully integrated at design stage.

- Development and integration of connections and interfaces with all balustrades and glazing by third parties.

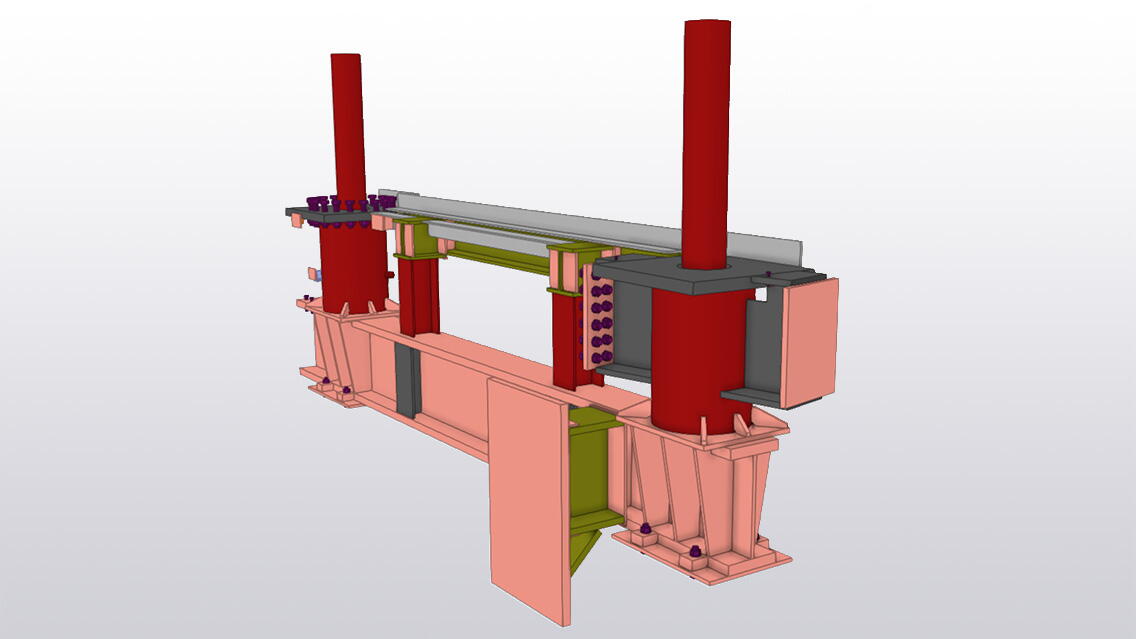

- Developing highly loaded connection designs that delivered on structural and security requirements while also meeting both the architectural and spatial requirements whether they remained visible or interfaced with the cladding finishes.

The above challenges were further exacerbated by the arrival of COVID. With all parties working remotely, IFCs, clash detection and Trimble Connect became absolutely critical tools to enable development, coordination and communication of the design challenges that had to be overcome.

Developing the buildability of what was a large and challenging structure with complex connections, geometry and interfaces, and then for that to later lead to successfully delivering the project in the most complex of environments is a challenge worthy of celebration.

Using Tekla software

- The majority of profiling, cutting and drilling was undertaken by specialist suppliers with full CNC operating systems. They were provided with both the NC and PDF files for each component, exported directly from Tekla Structures.

- In order to maximise DfMA targets and minimise work on site, once assemblies were initially developed and modelled, IFCs for the individual assemblies were used to assess transportation constraints. This included swept path analysis, and also to review crane lifting operations to ensure weights and size were compatible with site restrictions. Many times this review process triggered a change to the design that proved critical later on site.

- “Marked Category” was used to create additional sub-phases that allowed better management of the process of issuing components to manufacture. This also helped where certain parts of a work phase could not be issued due to an ongoing design change, for example, ensuring additional sub phasing was possible to better track these components.

- Proposed connections would first be modelled in Tekla and then the files exported to the connection design software where calculations would be run and further development of the connections undertaken. This process ensured the practical requirements were understood from an installation perspective by the structural engineer, thereby ensuring an element of autonomy for them to develop the final calculations or make amendments with a high degree of confidence that no rework would be required.

- Due to the complexity of the connection and loading arrangements, IDEA StatiCa was utilised to develop the connection design. The process for communicating any updated connection design from IDEA StatiCa to Tekla followed a more traditional approach in that, the connection design report was issued to the detailers along with the updated connection model from IDEA StatiCa and changes were subsequently updated directly by the detailer within the main Tekla Structures model.

- Changes communicated by the design team would be incorporated into Kilnbridge Construction Services’s Tekla model and would then be reviewed as part of a regular model exchange process, to ensure that any updates would not cause any secondary clashes or impacts as a result.

What does Kilnbridge Construction Services Limited say about the project?

“Over the last number of years, we have always had the goal of having a Steel Structures entry into the Tekla awards, but we also felt it needed to be the right project and we believe this one is. Steelwork detailers normally operate in the background of every construction project and are rarely if ever exposed to the external appreciation or plaudits that the more visible construction roles are. They provide a critical role in the planning, Health and Safety, construction methodology development, as it is in this design phase of the project that the majority of those decisions are made and on this project alone, our detailers were responsible for identifying and flagging numerous emerging issues during the model development that may otherwise have gone unnoticed and proved costly later in the project. The Tekla Awards provide a unique opportunity not only for the companies who undertake these projects to be recognised, but just as importantly, to acknowledge specifically, the invaluable contribution made by the individuals involved in design and detailing roles by giving us a platform to promote their achievements.

The continued development of Tekla meant that in recent years its increased versatility and capabilities has meant that virtually all our detailing responsibilities for our works can be delivered within one software package (Tekla) meaning we have been able to more effectively coordinate not only our own works, but with other interfacing contractors on our projects. This capability to incorporate such a diverse range of work into one model has allowed us to not only streamline our design process but also to better support our client with their coordination also.”

- Terry Murphy, Technical Director at Kilnbridge Construction Services Limited