When Icarus LSF were appointed, the client and main contractor required confirmation that disruptions would be kept to a minimum throughout delivery and installation, as the existing building would still be in use.

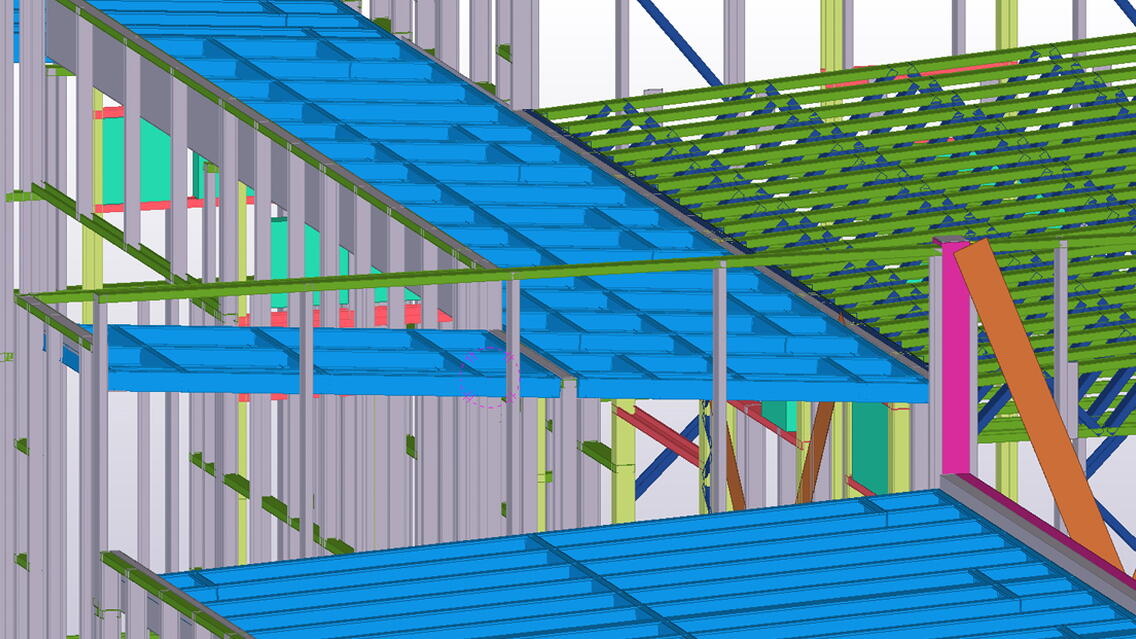

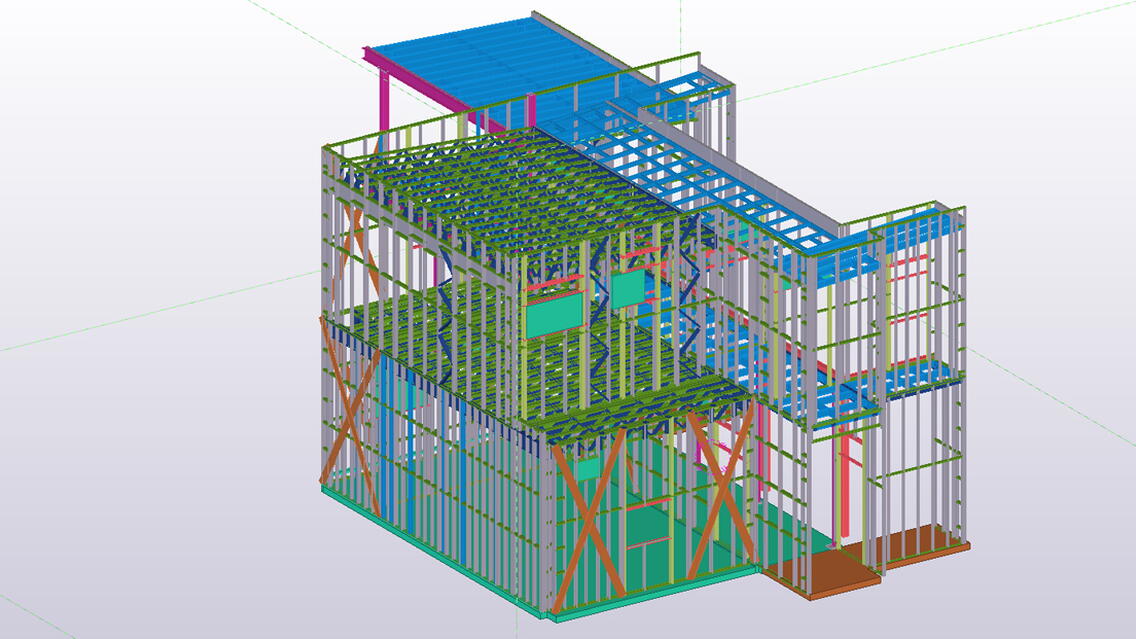

Whilst the extension would be independent of the existing building, it was still erected in a close proximity to the existing; only allowing for a 20mm tolerance to the finishes, which were applied prior to site installation. The frames directly facing the existing building were to be boarded with external board. Models and reference drawings for the existing building were crucial in identifying the affected frames.

There was also a walkway created from hot rolled steel connecting the extension and main hospital to design and install. We required third party information in order to create the required voids and services for the vast amount of services running through the build. Incorporating others models made this a lot easier to achieve the co-ordination. By using Tekla combined with the knowledge of our designers, when it came to planning deliveries the schedule was kept to a minimum by using the phasing and lotting tool to their full potential.

From the initial design inception, the client was given access to the Tekla model, which was used for the coordination of interfaces between the light gauge steel and other construction disciplines such as M&E. The ease of use of the model and various visualisation techniques allowed practical integration of other services as a timely cost effective process, which was important as function had priority in this project. The success of completing design and manufacture within the required timescales came from using a highly engineered product, using advanced CAD/CAM techniques. 3D modelling and BIM was used to ensure quality transpired through each stage of the project.