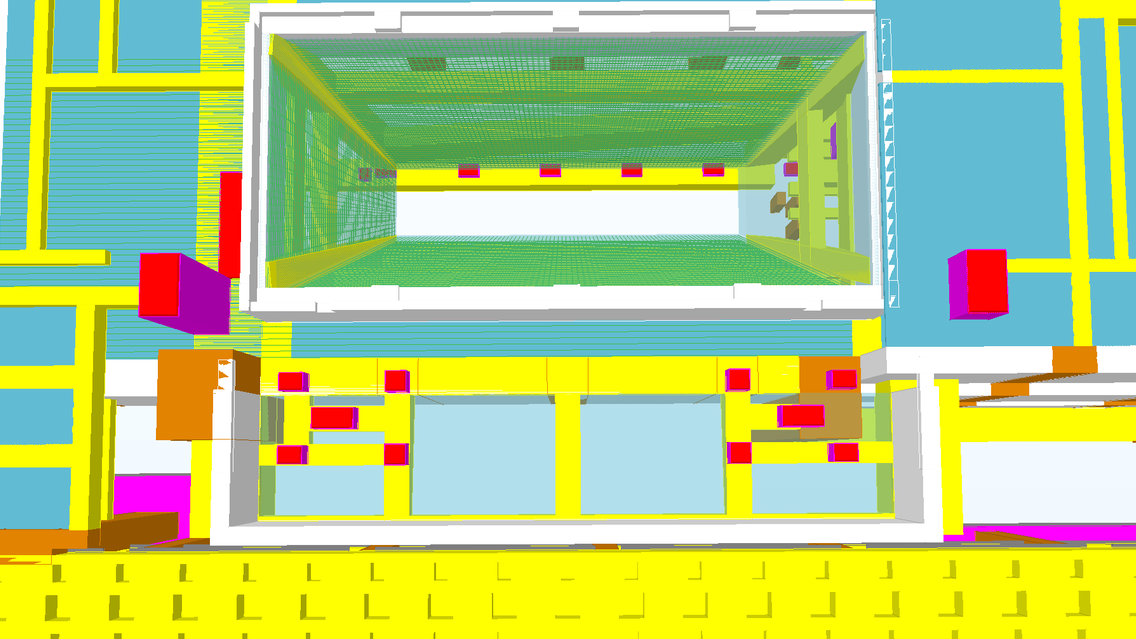

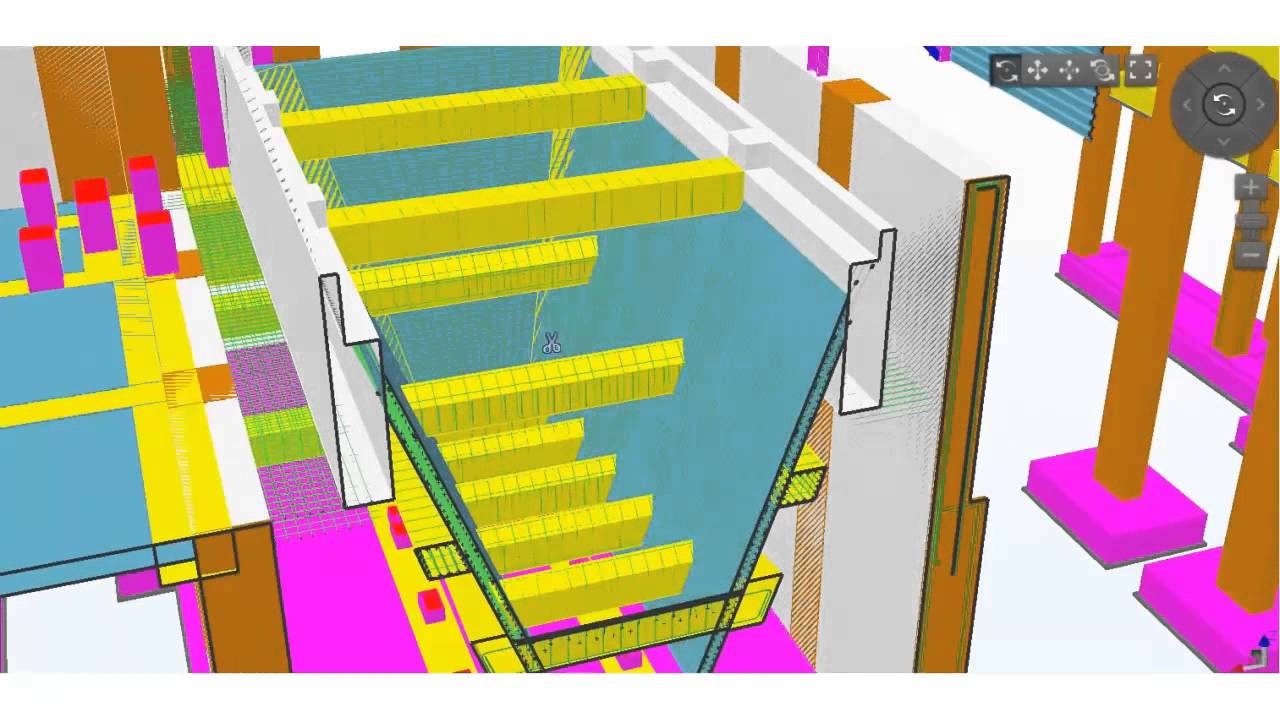

Wagon Tippler systems are generally provided in the power plants and ports for unloading the material from the wagons. The wagon tippling system consists of wagon tippler, the wagon positioning equipment, underground hopper, and feeder below the hopper for evacuating the material unloaded into the hopper. The unloading cycle starts when the wagon is positioned over the wagon tippler table and the wagon along with the table rotates and discharges the material into the hopper. There are two types of wagon tipplers viz. rotaside which rotates about 135º and another rotary type which rotates by 180º. The rotaside wagon tipplers are provided in most of the plants in India.

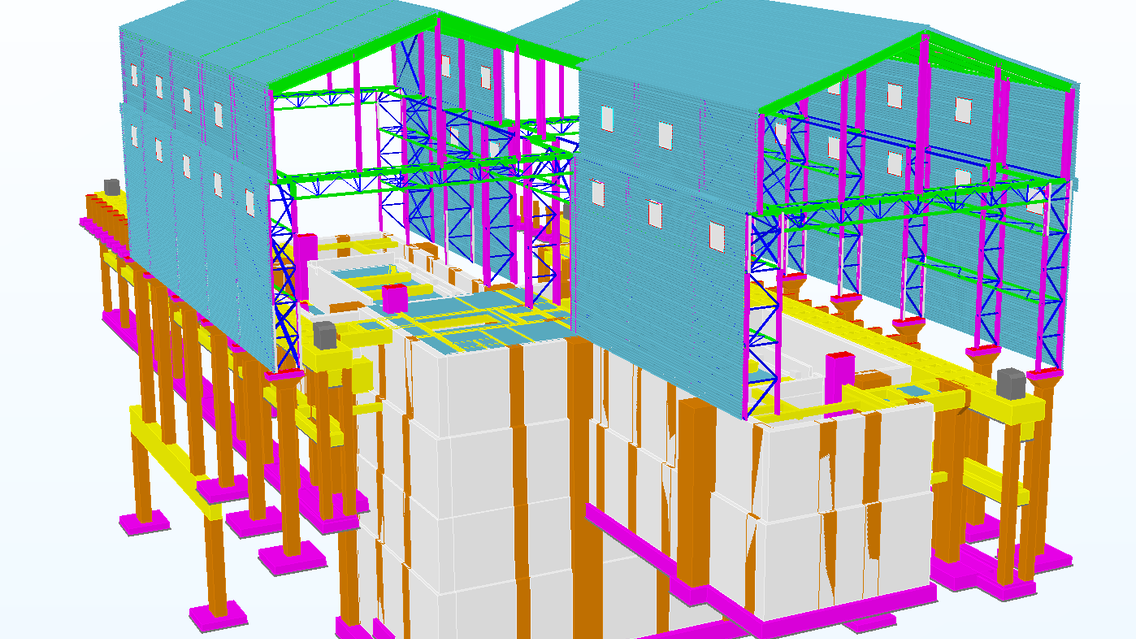

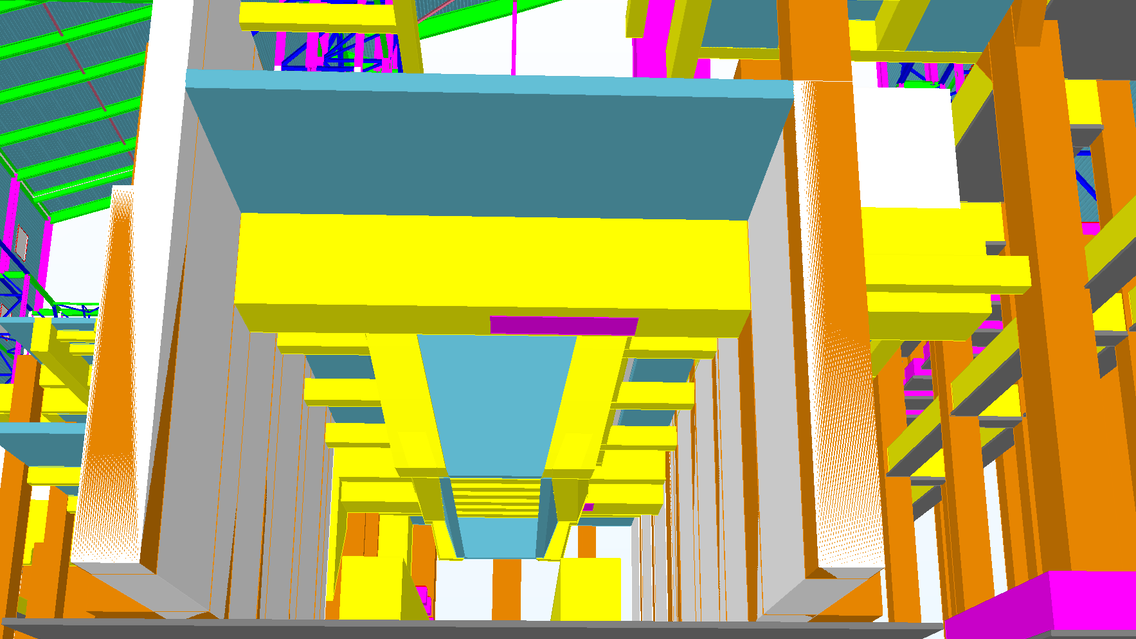

The Wagon Tippler Complex consists of both super structure shed with EOT Crane and Underground RCC structure. Overall dimension of 85 (L) x 40 (W) x 32 (H). Hoper with grizzly grating is provided at the side of Wagon Tippler facilitates the material to pass apron feeder located below the hopper and finally gets discharged into the Conveyors.

Material Quantity :-

a) Concrete quantity – 5900 Cu. M.

b) Formwork – 15375 Sq. M.

c) Rebar – 905 MT.