The Sheikh Khalifa Bin Zayed Al Nahyan Masjed Project (SHKMP, Al Ain) is located at heart of Al Ain City, near U.A.E. University campus. This prestigious project is set to become one of the biggest mosque in U.A.E. with plot area of 256680 square meters and it will hold 20,000 worshippers when opens in 2016.

Designed with walk-friendly features, this Mosque is having easy access from the city by allowing old people to easily walk to the Prayer Halls without climbing any steps/escalators. This Project consists of the following structures.

1. Haram Building

2. Prayer Halls

3. Minaret Towers

4. Ablutions

5. Arcades

Eversendai Engineering LLC was awarded this complex project having the responsibilities of Detailed connections design and Engineering services, 3D Tekla Modeling works, Fabrication Drawings, Supply, Fabrication and Site Installation works. The total Tonnage of the project is 2,500 M Tons.

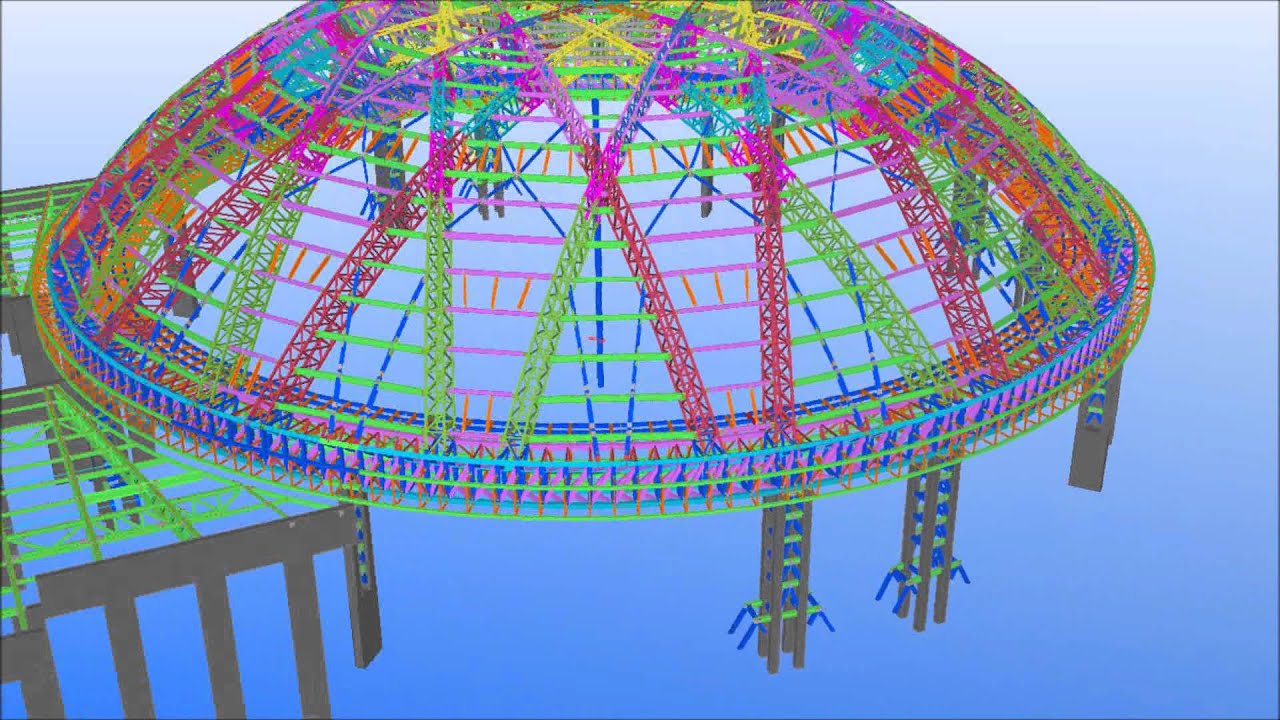

The Haram Building is a massive and complex steel dome structure supported by braced column frames at perimeter alone. This attractive large span steel dome structure is having exterior diameter of 86m and interior diameter of 75m and having interior height of 31.3m without having any internal columns. This dome structure is the largest among all mosques in U.A.E.

This Steel Dome is modeled by arranging 8 nos. of Main Rib 3D Trusses radially in plan. Each 3D Rib Truss consist of 2 top chords and 2 bottom chords connected by vertical members. Further, diagonal truss members were provided in both plan and side elevation thus forming complex 3D truss system for these main ribs. Another 8 Nos. of Secondary Rib Trusses arranged symmetrically between the Main Rib Trusses to form the dome 3D geometry. All these Main Rib Trusses and Secondary Rib Trusses were formed by using SHS sections and their connections were designed accordingly. Infill purlin members were provided in these Rib Trusses to support the cladding works above. These infill purlin members were formed by using UB/UC members.

By continuously coordinating with the Project Architects, the design intended complex 3 Dimensional curved geometry of the Rib Trusses was simplified greatly using Tekla software so that these steel Rib Trusses shall be fabricated at workshop.

This steel dome is supported along its perimeter by using 3D Tension Ring Truss. This Tension Ring Truss consists of 2 top chords and 2 bottom chords, connected by verticals and diagonals at all 4 sides. In order to receive the Rib Trusses above, the SHS top chords of the Tension Ring Truss were arranged in Diamond Shaped cross section instead of Square cross section. By continuously coordinating with the Project Architects, this design intended complex Tension Ring Truss geometry with Diamond shaped cross sections were simplified greatly using Tekla software so that these trusses shall be fabricated at workshop. The complex connections of these Trusses (more than 10 SHS members connecting at same node) with precise load path were modeled with great ease in Tekla software by using its user friendly options.

Apart from the above, there were HVAC ducts passing through these Rib Trusses and Tension Ring Trusses along its axis. This was further coordinated with HVAC contractor and various clashes identified using Tekla and Bimsight softwares. These clashes were easily resolved through various BIM coordination meetings. Also, BIM coordination was carried out with other trades and their requirements were taken care well before generating the fabrication drawings.

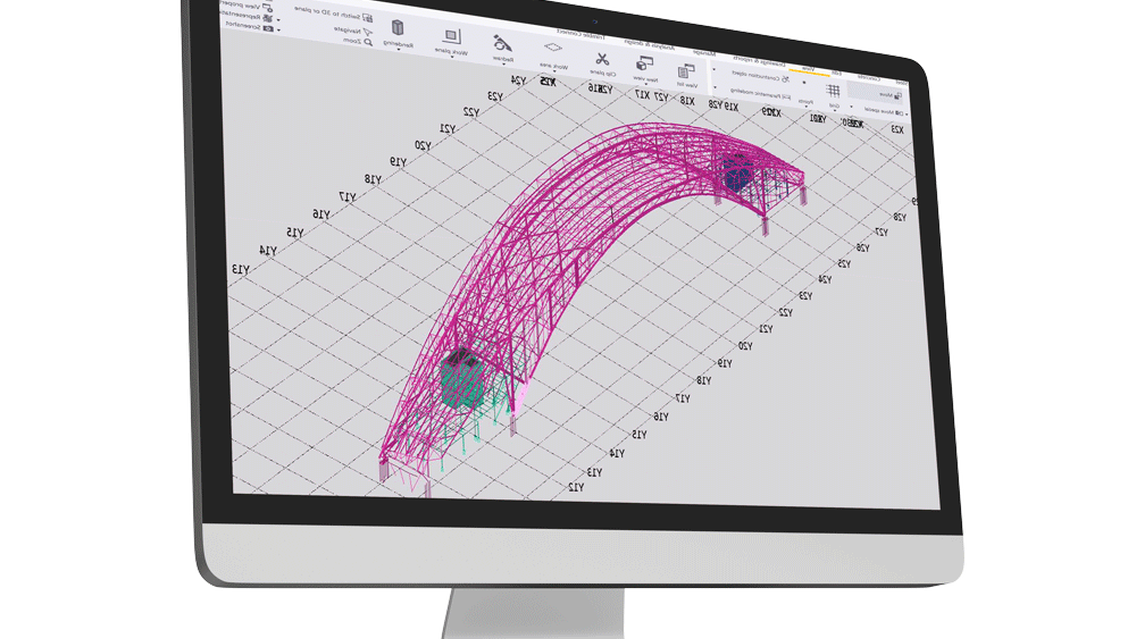

The Minaret Towers are approximately 75m high from the ground. Steel Structure for these Minarets start from level +36.9m. These Minaret Steel Structures consist of perimeter steel columns tied with main CHS Column at intermediate levels. The CHS Steel Column is supporting the spiral stair case, giving access to the top of the Minarets. Tekla and Bim sight were greatly helpful to identify and resolve the headroom clashes due to encroachment of intermediate tie beams in the spiral staircase welded with central CHS column. The arcades consist of steel arches whose geometry was arrived by continuous coordination with stone cladding contractor. The Prayer Hall consists of steel trusses supporting composite deck slab above.