THE PROJECT

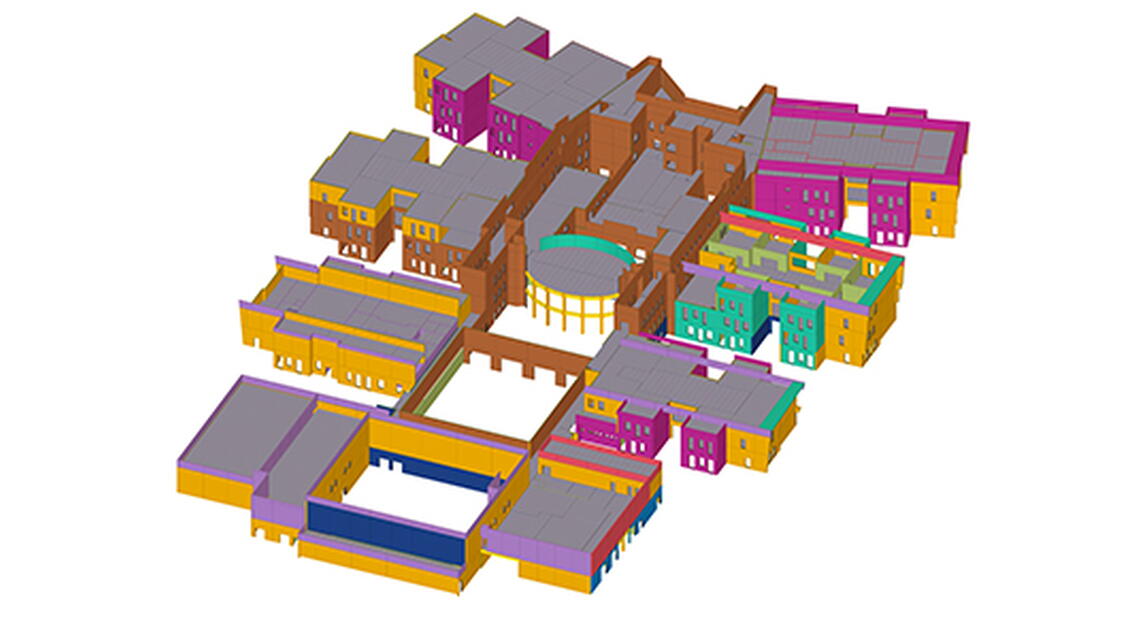

The project consists of ‘12’ blocks with different floors starting from Ground + roof till G + 2nd + Roof, with different types of precast/pre-stressed elements (precast & Pre-stressed Beams, solid slab and Hollow core slabs, precast columns, insulation walls with different thickness, solid load bearing wall, Non-Load bearing wall and staircases with different designs.

CHALLENGE AND SUCCESS FACTORS

GULF PRECAST CONCRETE CO LLC had taken on big challenge with this project as the baseline programme was very tight after obtaining the approval on drawings form very difficult consultants, in addition, huge efforts were required from all departments to achieve the project's target in a short-time, therefore, the most important success factor that leas to a speedy start of this project was the hard work and effort of the engineers. They carried out a high degree of coordination in terms of drawing submissions, fabrication drawings for MEP, production, and installation.

The engineers even coordinated several meetings with the main contractors finalizing MEP and other services as well.

WHY TEKLA

Tekla helped a great deal for the entire design team to successfully work collaboratively. BIM is a great way to work collaboratively with the entire design team. If used correctly, it allows you to check that the design is fully co-ordinated in a way that traditional methods could never have allowed for. This reduces error, which makes the process run much more smoothly as well as protecting the initial concept.

ABOUT GULF PRECAST CONCRETE CO L.L.C.

Gulf Precast is a UAE Leader in Precast Manufacturing. With more than 30 years of experience, it has expanded from its original United Arab Emirates center of operations and is now active in Saudi Arabia as well. It proposes a wide range of Precast Products, holds main contracting licenses and is constantly increasing its market share. Based on a strategy of international expansion, Gulf Precast has been awarded several major developments in the Kingdom of Saudi Arabia.

With six fixed precast manufacturing factories, four in Abu Dhabi and two in Dubai, the Company can produce up to 1,240 M3 per day, which is the largest precast capability in the UAE