EVERSENDAI Engineering LLC U.A.E was awarded 6,500 M Tons of CRESCENT CITY TOWER Project lacated in Baku. The scope of Eversendai was to provide Detailed Connection Design, Shop Drawings, BIM Implimentation & Coordination, Erection Engineering Study & Stage Analysis, Workshop Fabrication Drawings, Supply, Fabrication, Painting, Fire Proofing, Composite Floor Decking, and Erection of Structural Steel Works. All the above scope of works was completely taken care in-house and successfully completed in line with project schedules.

The Gilan Holding LLC are the client, AECOM are the Construction managers & Supervision Consultant, Derby Consultants are Structural Engineers for the Crescent City tower project.

The Crescent City” tower is part of a prestigious 450,000 square-meter mixed-used development “The Crescent Development Project” in the heart of Baku, Azerbaijan; on the banks of Caspian Sea.

The Crescent City, is a 192 meter skyscraper with 41 over ground levels. The building is elliptical shaped cylinder and slightly flattened at the north-south direction. The bottom of the tower is narrow, widens up to Level 29 and slightly narrow as it approaches the top, which includes a slanted cut notch at top. The shape of "The Crescent City" is architecturally designed to resemble a Torch.

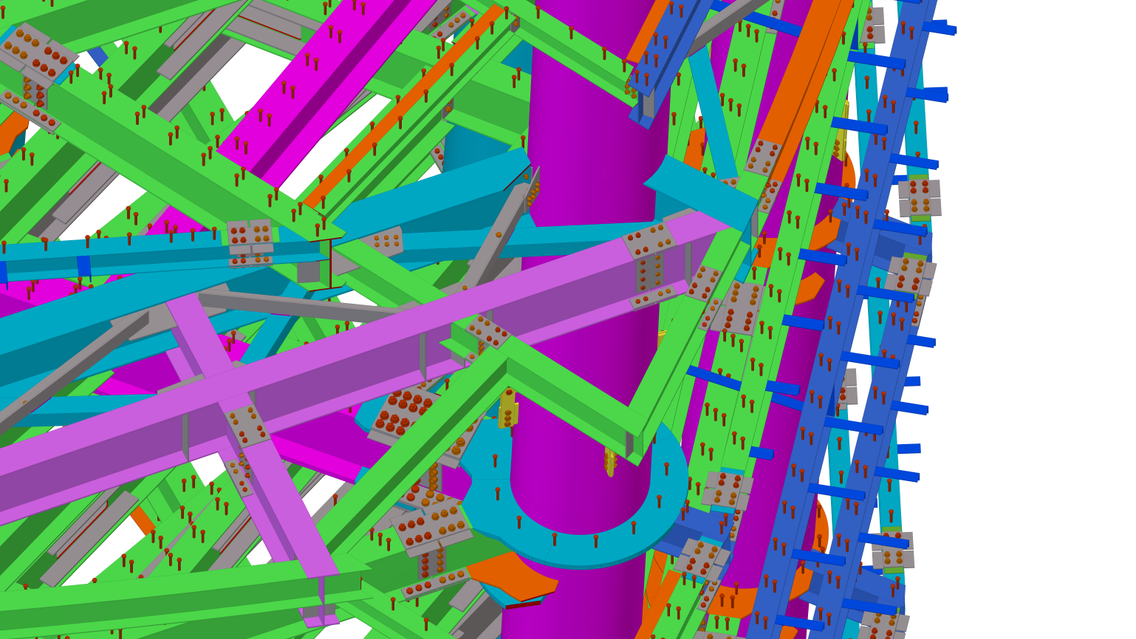

Structurally the Tower is having dual system with central concrete core wall and circular steel shelled concrete infill composite columns around the perimeter. The steel shell of the Columns are of size 1300mm dia x 25mm thk & 1000mm dia x 20mm thk up to level 20 and are of 1000mm dia x 20mm thk & 850mm dia x 20mm/16mm thk above level 20. The typical floor height is 4200mm. The floor system consists of deck slab with radial composite steel beams supported between core wall & composite columns and the steel tie beams between composite columns around the perimeter. The floor beams are coped near the core wall and provided with web openings along the span for the purpose of MEP ducts to pass through.

A strong structural steel outrigger bracing system provided between levels L19 & L20. The concrete core wall is reinforced with full length centrally placed steel placed for the full height between the outrigger floor levels.

The Top four levels of the Crown structural steel framing consists of free standing columns and curved rolled pipe sections to support the glass façade brackets.

TEKLA 3D software is used for the complete 3D modeling of this structure precisely in line with the architectural geometry and with all structural steel components including steel members, emdeds, connections, web cutouts, strengthening plates, curved members etc. The same 3D model is effectively used to coordinate and incorporate the concrete contractor’s slip form penetrations requirements at outrigger levels and the façade contractor’s bracket requirements at Crown level.