Digital fabrication: The Integrated Construction and Prefabrication Hub

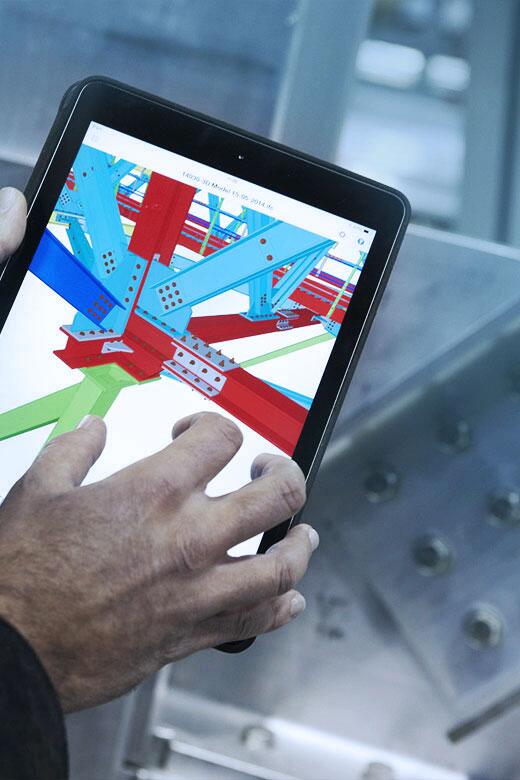

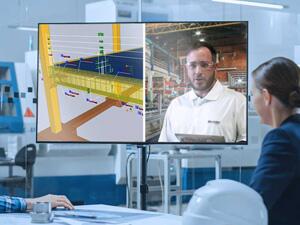

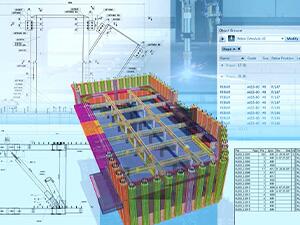

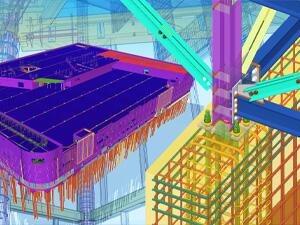

Learn how the fabrication process at SoilBuild’s Integrated Construction and Prefabrication Hub (ICPH) is driven by the Tekla BIM solutions and how Tekla Structures became central to their operations.